Seals for sealing high-pressure media in cylindrical spaces

A technology of high-pressure medium and seals, which is applied in the direction of engine seals, engine components, mechanical equipment, etc., can solve the problems of main seals being easy to break, and achieve the effect of preventing breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

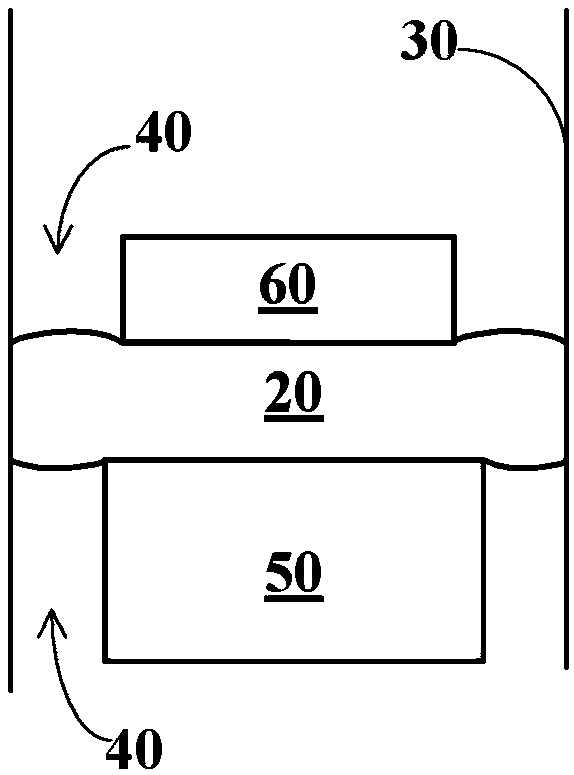

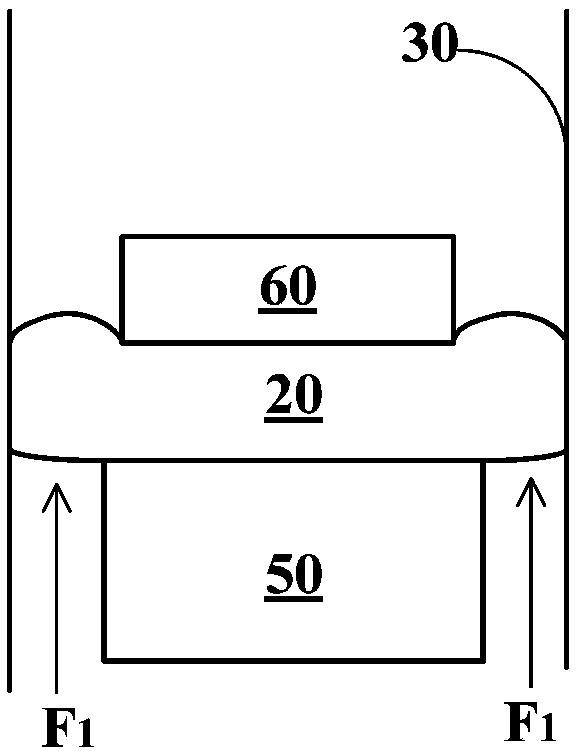

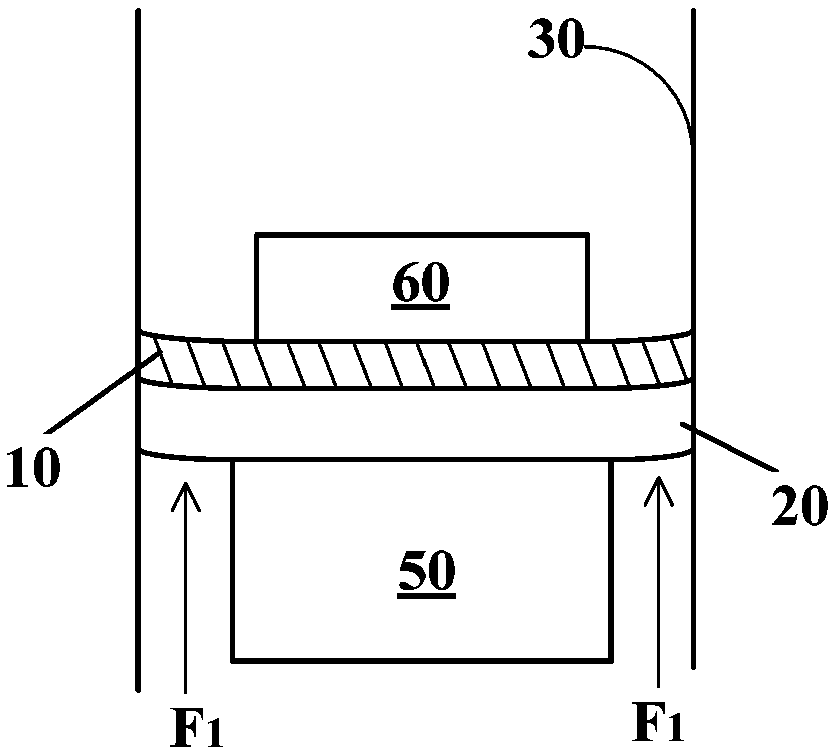

[0051] The terms "longitudinal", "transverse", and "upward" described below are preceded by image 3 as a benchmark.

[0052]An auxiliary seal 10 for sealing a cylindrical space 40, the hardness of the auxiliary seal 10 is greater than that of the main seal 20 and has elasticity. When the auxiliary seal 10 and the main seal 20 are both placed in the cylindrical space 40 extending in the longitudinal direction formed by the first member to be sealed 30, the pressure applying member 60 and the pressure receiving member 50, and the auxiliary seal When 10 and the main seal 20 interfere with each other in the longitudinal direction and are placed on the pressure-bearing member 50, the auxiliary seal 10 is defined as using the pressure applicator 60 to apply longitudinal sealing pressure to the auxiliary seal 10 and the main seal 20, When the primary seal 20 deforms laterally and seals against the first member 30 to be sealed, the auxiliary seal 10 deforms laterally and interferes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com