Shift register, driving method thereof, gate driving circuit and display device

A technology of shift registers and potentials, which is applied in static memory, digital memory information, instruments, etc., can solve the problems of inability to realize low-frequency, low-power drive, etc., and achieve the effect of low-power drive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

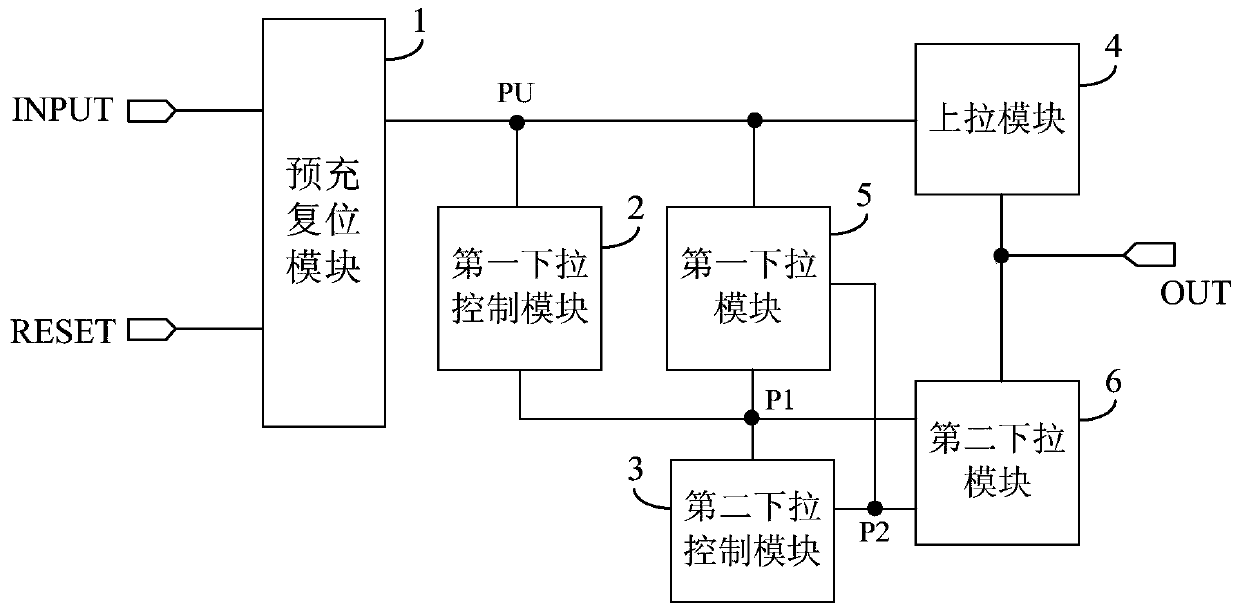

[0053] figure 1 A schematic structural diagram of a shift register provided in Embodiment 1 of the present invention, as shown in figure 1 As shown, the shift register includes: a pre-charge reset module 1, a first pull-down control module 2, a second pull-down control module 3, a first pull-down module 5, a second pull-down module 6 and a pull-up module 4, wherein, The pre-charge reset module 1, the first pull-down control module 2, and the pull-up module 4 are connected to the pull-up node PU, and the first pull-down control module 2, the first pull-down module 5, and the second pull-down module 6 are connected to the first pull-down node PU. The pull-down node P1, the second pull-down module 6, the first pull-down module 5, and the second pull-down module 6 are connected to the second pull-down node P2, and the second pull-down control module 3 is also connected to the first pull-down node P1.

[0054] The precharge reset module 1 is used to precharge or reset the pull-up ...

Embodiment 2

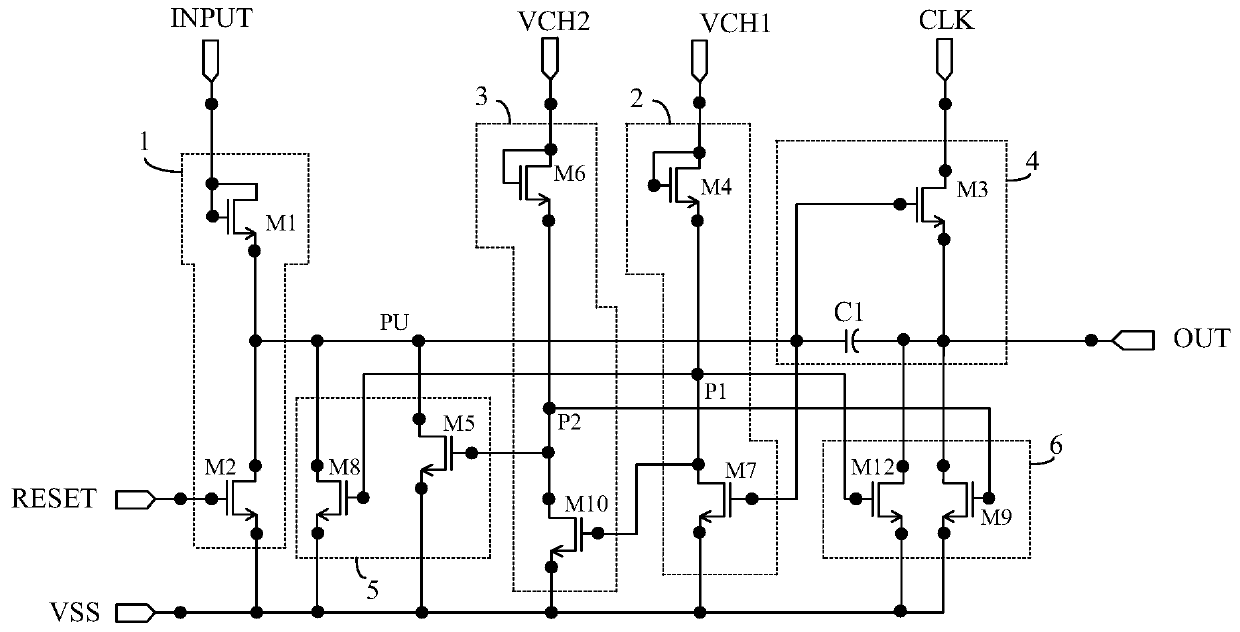

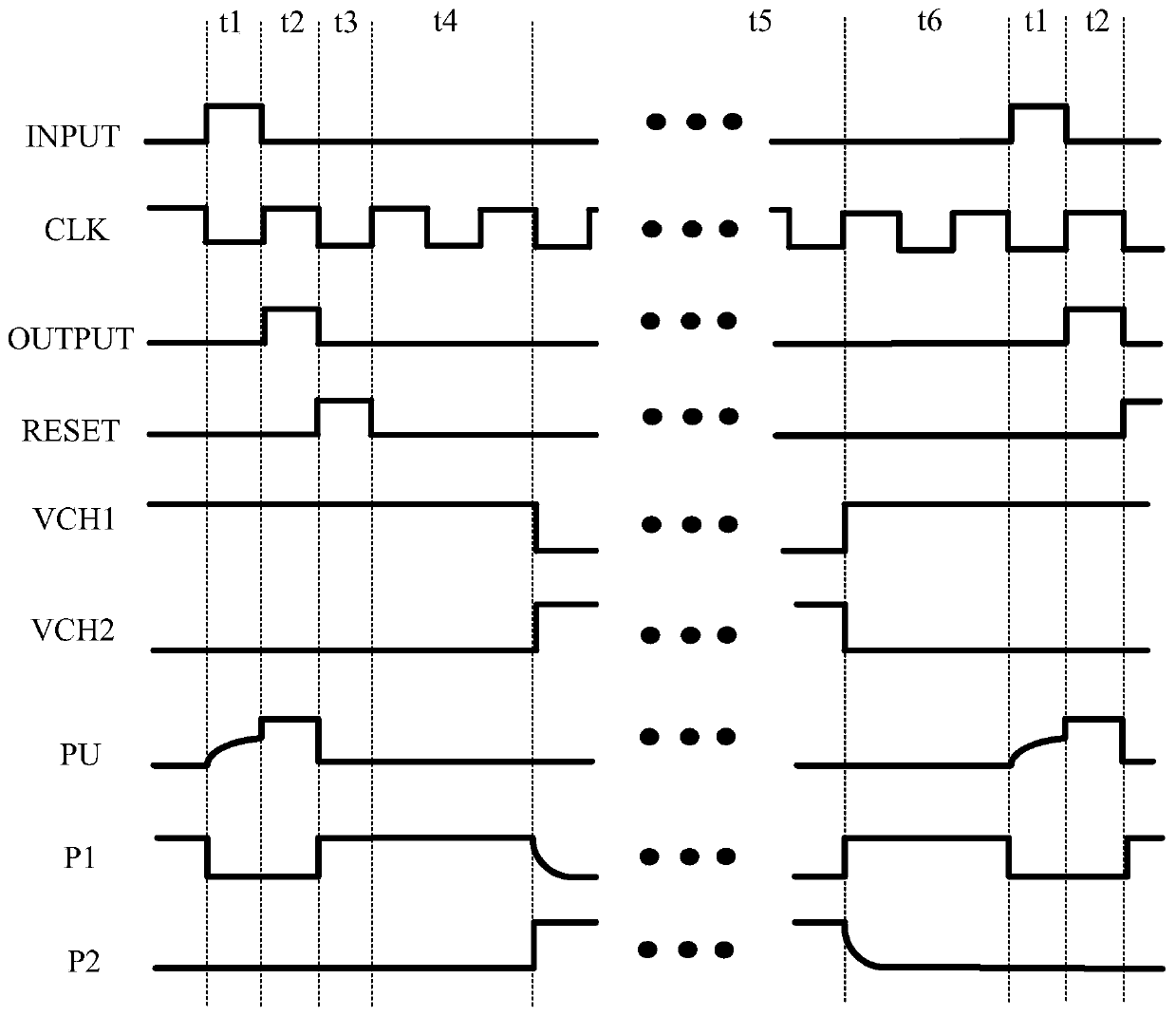

[0063] figure 2 It is a schematic structural diagram of a shift register provided by Embodiment 2 of the present invention, image 3 for figure 2 The working timing diagram of the shift register shown, such as figure 2 and image 3 as shown, figure 2 The shift register shown is based on figure 1 One specific implementation of the shift register shown.

[0064] Optionally, the first pull-down control module 2 includes: a fourth transistor M4 and a seventh transistor M7; wherein, the control electrode of the fourth transistor M4 is connected to the first electrode of the fourth transistor M4, and the first electrode of the fourth transistor M4 pole is connected to the first variable power supply terminal VCH1, the second pole of the fourth transistor M4 is connected to the first pull-down node P1; the control pole of the seventh transistor M7 is connected to the pull-up node PU, and the first pole of the seventh transistor M7 It is connected with the first pull-down no...

Embodiment 3

[0111] Figure 4 A flow chart of a driving method for a shift register provided in Embodiment 3 of the present invention, such as Figure 4 As shown, wherein, the shift register adopts the shift register provided in the first embodiment or the second embodiment above, and the driving method of the shift register includes:

[0112] Step S1 , the precharge reset module precharges the pull-up node under the control of the precharge signal input from the precharge signal input terminal.

[0113] Step S2 , the pull-up module sends the clock control signal in the clock control signal line to the signal output terminal under the control of the potential of the pull-up node, and the signal output terminal outputs a driving voltage.

[0114] Step S3, the pre-charge reset module resets the pull-up node under the control of the reset signal input by the reset signal input terminal, and the second pull-down module outputs the signal under the control of the potentials of the first pull-d...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap