Testing device for dynamic rigidity of engine suspension

An engine mount and testing device technology, which is applied in the testing of machine/structural components, measuring devices, and elasticity testing, etc., can solve the problems of low testing accuracy of engine mount dynamic stiffness, and achieve the effect of accurate dynamic stiffness value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

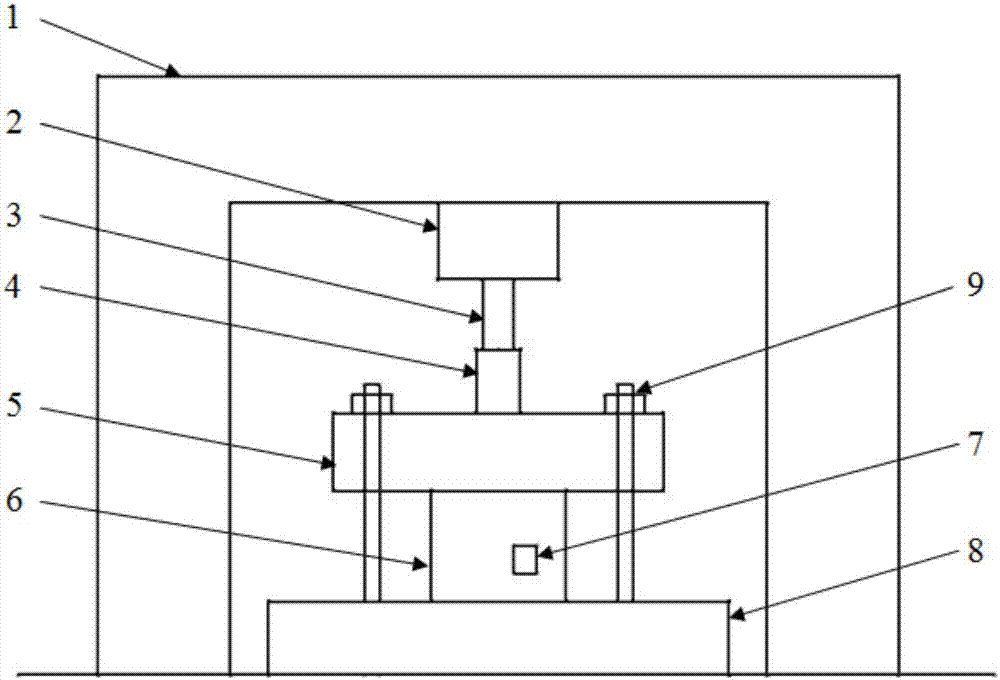

[0027] Utilize the present invention to test the dynamic stiffness of the engine rubber mount provided by a military diesel engine research institute, including a control system 1, a vibrator 2, an exciting rod 3, a force hammer 4, a preloaded mass 5, a mount to be tested 6, Sensor 7, base 8 and bolt 9; as figure 1 shown.

[0028] Connection relationship:

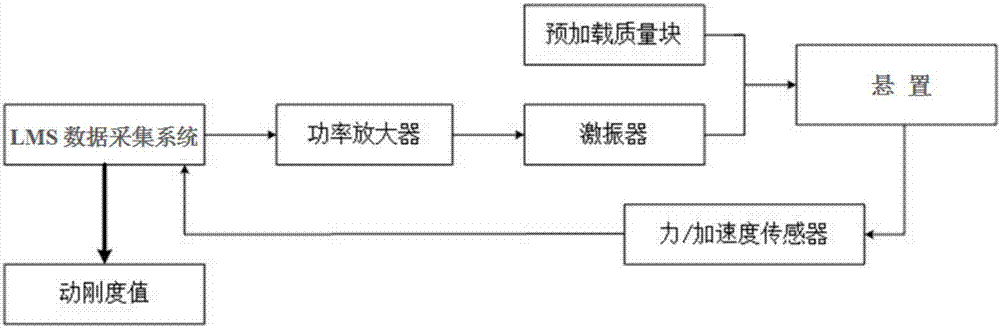

[0029] The control system 1 includes a 32-channel LMS data acquisition system and a power amplifier; one end of the power amplifier is connected to the 32-channel LMS data acquisition system, and the other end is connected to the exciter 2;

[0030] The suspension to be tested 6 and the preloaded mass 5 are placed in sequence above the base 8, and then the suspension to be tested 6 and the preloaded mass 5 are fixedly installed on the base 8 through the bolt 9; the suspension to be tested can be adjusted by adjusting the bolt 9 Set 6 to apply different preloads; the top of the preloaded mass 5 is fixedly connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com