New energy automobile charging pile with high safety

A new energy vehicle and safety technology, applied in electric vehicle charging technology, charging stations, electric vehicles, etc., can solve the problems of fire, bulky charging piles, low safety, etc., to improve stability and improve charging safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

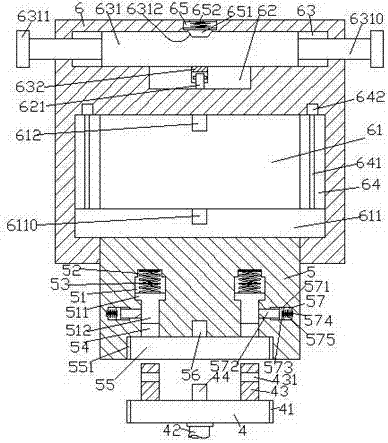

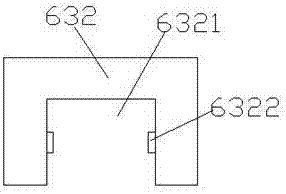

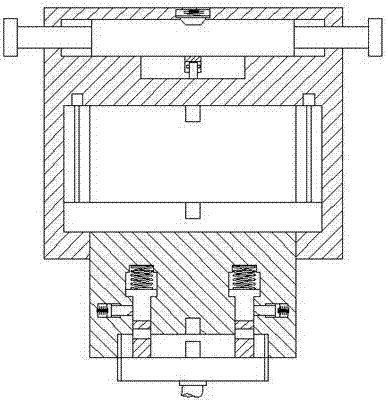

[0022] Such as Figure 1-Figure 8 As shown, a high-safety new energy vehicle charging pile of the present invention includes a body 6 and a charging gun head 4 provided at the bottom of the body 6. The bottom of the body 6 is provided with an accommodation chamber 61, and the accommodation chamber The left and right sides of 61 are provided with sliding grooves 64, and the described sliding grooves 64 are provided with screw rods 641, the top of the described screw rods 641 is connected with the power of the motor 642, and the accommodating cavity 61 is provided with moving beams 611. Both ends of the beam 611 extend into the sliding groove 64 and are threadedly connected with the screw rod 641. The bottom of the moving beam 611 is provided with a connecting block 5, and the bottom of the connecting block 5 passes through the bottom wall of the body 6 and slides Cooperate with the connection, the inside of the connecting block 5 is left and right symmetrically provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com