A shaft-disc type take-up and pay-off device for vibration and shock real ship testing

A technology of take-up and pay-off device and shaft disc, which is applied in the field of shaft-disk type take-up and pay-off devices, can solve the problems of messy take-up, heavy workload, and long wiring time, so as to improve experimental efficiency, control the margin, avoid The effect of cross-winding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

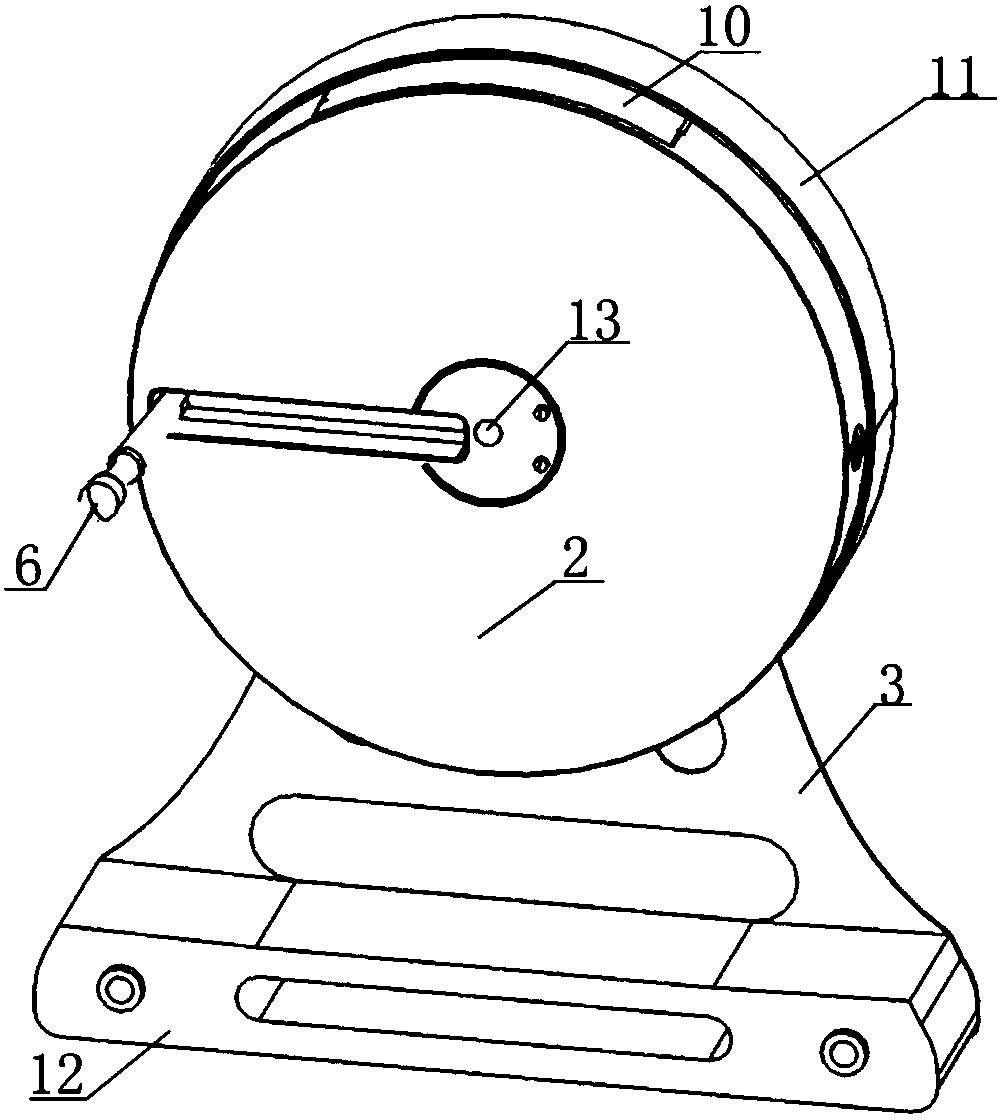

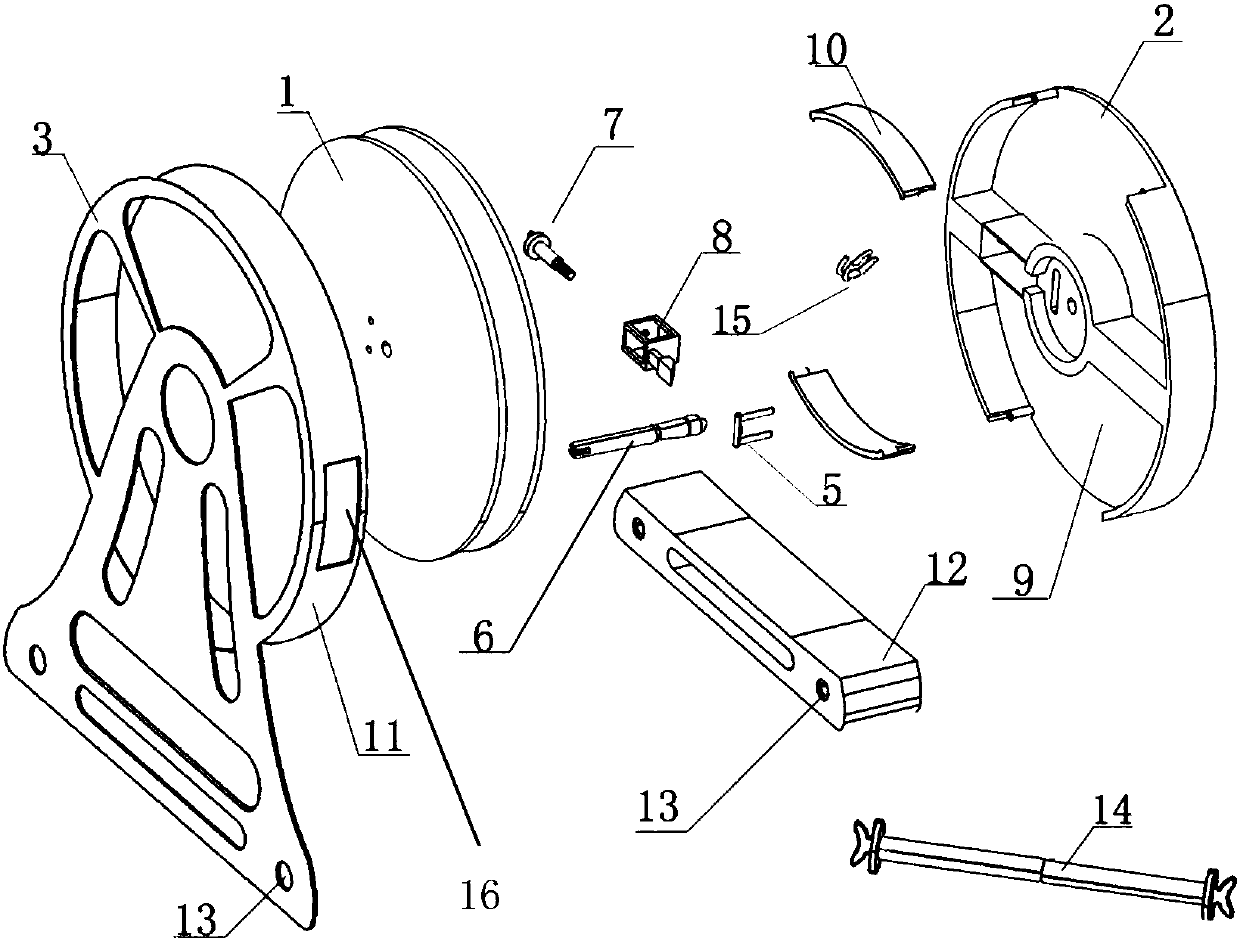

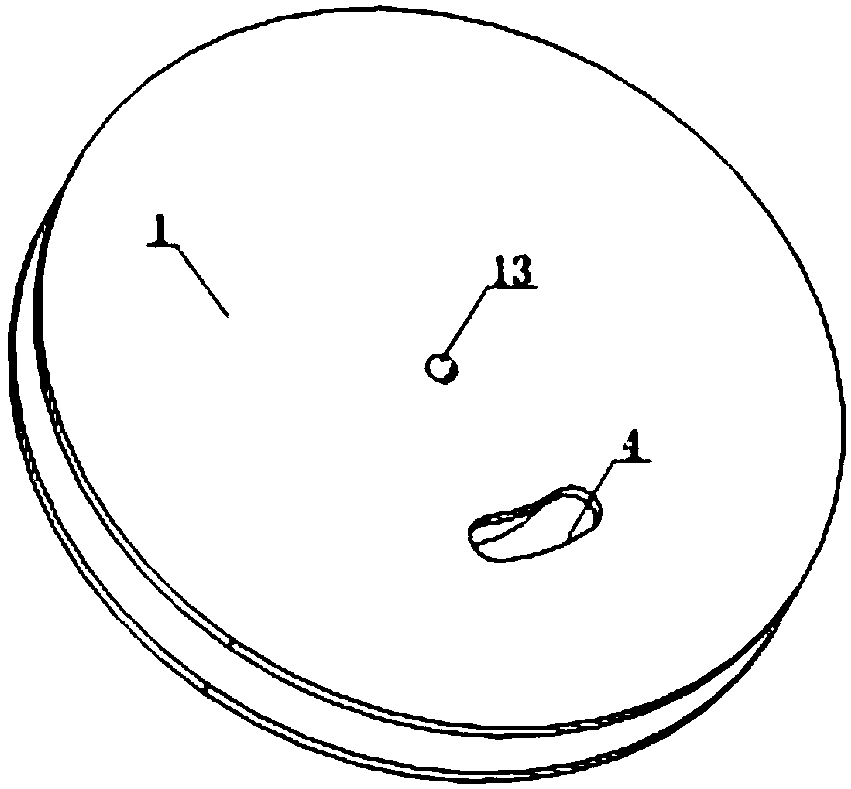

[0019] to combine Figure 1 to Figure 4 , the present invention is described in detail in a row arrangement: the reel 1 of the present invention is fixed to the bobbin reel 2 with a buckle through the central shaft 13, and a wire hole 4 is provided between the two; two holes are arranged on the outer side of the reel 1 , used to match and connect with the double round rods 5; the outer surface of the buckle spool 2 is embedded with a groove, and a folding rocker 6 is provided; the inside of the buckle spool 2 is provided with a knob buckle rod 7, through the rod end The screw thread of the part is connected with the square frame side of the push block 8; the return spring 15 is arranged in the middle of the push block 8, and is connected with the rigid structure of the buckle holding bobbin disk; The double round rods 5 are in slidin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com