Compartment dumping mechanism of agricultural carrier vehicle

A technology of dumping mechanism and transport vehicle, which is applied in the direction of tilting and carrying vehicles, and can solve the problems of low ground height of dumping and flipping hinges and small dumping and flipping angles of carriages, and achieves simple structure and large dumping and flipping angles Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

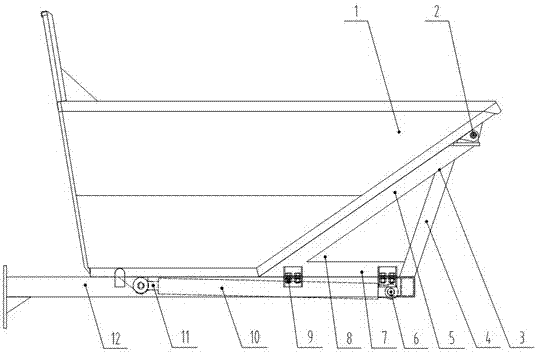

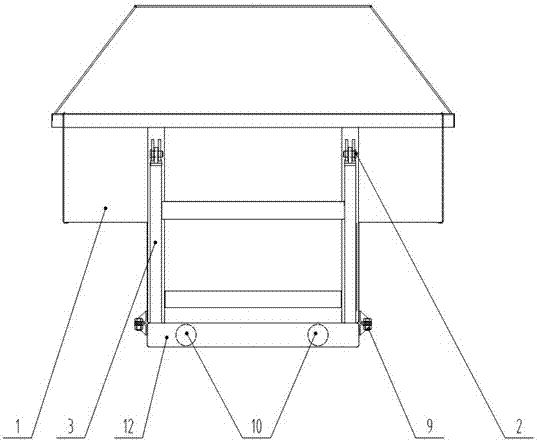

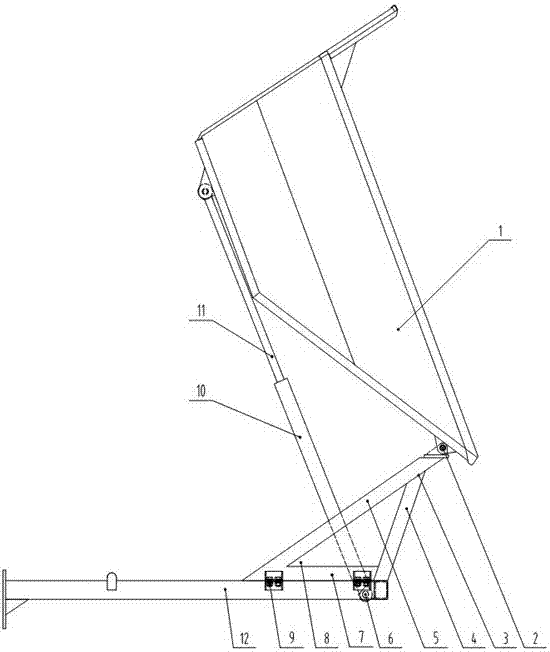

[0013] like figure 1 , figure 2 , image 3 As shown, the present invention mainly includes a carriage assembly 1 and a vehicle frame assembly 12 . figure 1 Shown is the front view structure of the present invention, the rear view structure of the present invention and figure 1 The main view structure of is the same, in order to describe more simply and clearly, this embodiment only figure 1 The main view structure is described. like figure 1 The vehicle frame assembly 12 shown in the present invention is used to carry the carriage assembly 1 , and is realized by the lifting cylinder 10 and the vehicle frame turning frame assembly 3 . At the rear of the vehicle frame assembly 12, the vehicle frame overturning frame assembly 3 is fixed by a combined bolt 9, and the vehicle frame overturning assembly 3 is connected in a triangle by the overturning frame fixing rod 7, the overturning frame supporting rod 4 and the overturning frame connecting rod 5. composed as figure 1 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com