Centrifugal compressor

A technology for centrifugal compressors and casings, applied in mechanical equipment, engine control, engine manufacturing, etc., can solve problems such as performance degradation, air leakage, and complex drive mechanisms, and achieve the effect of reducing surge limit flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

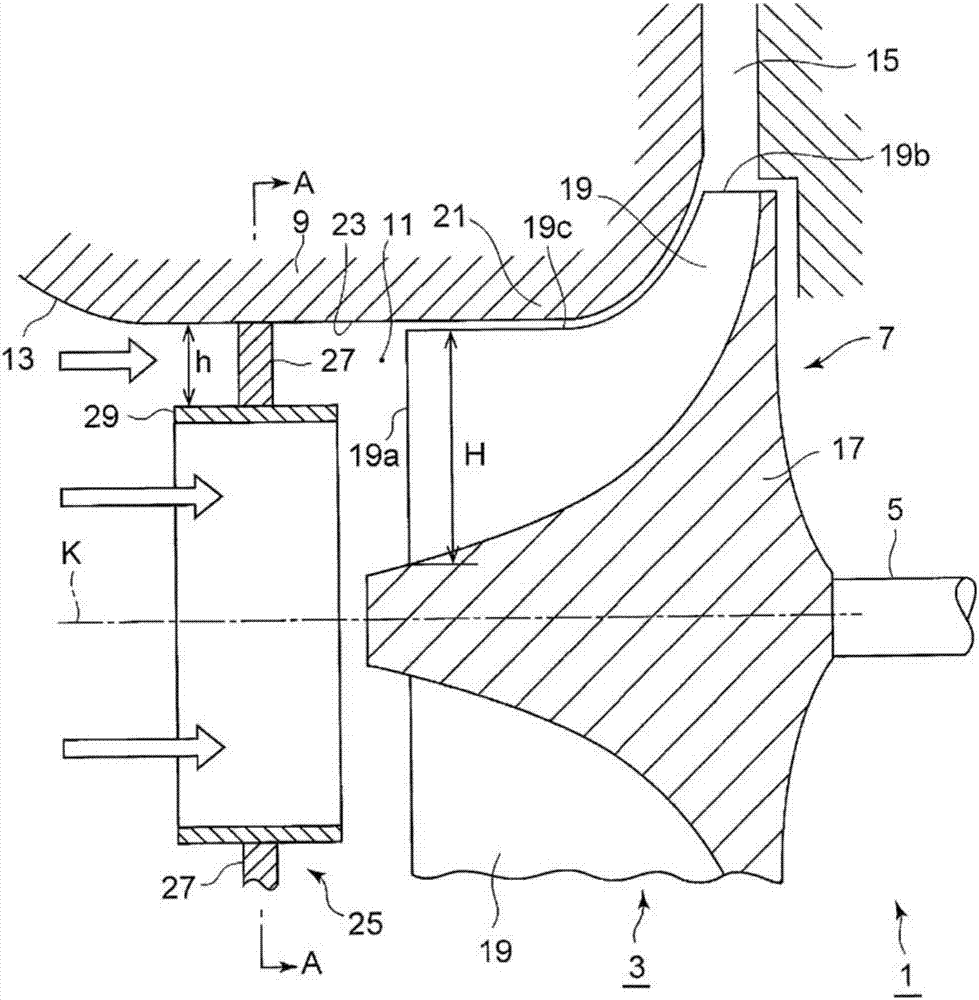

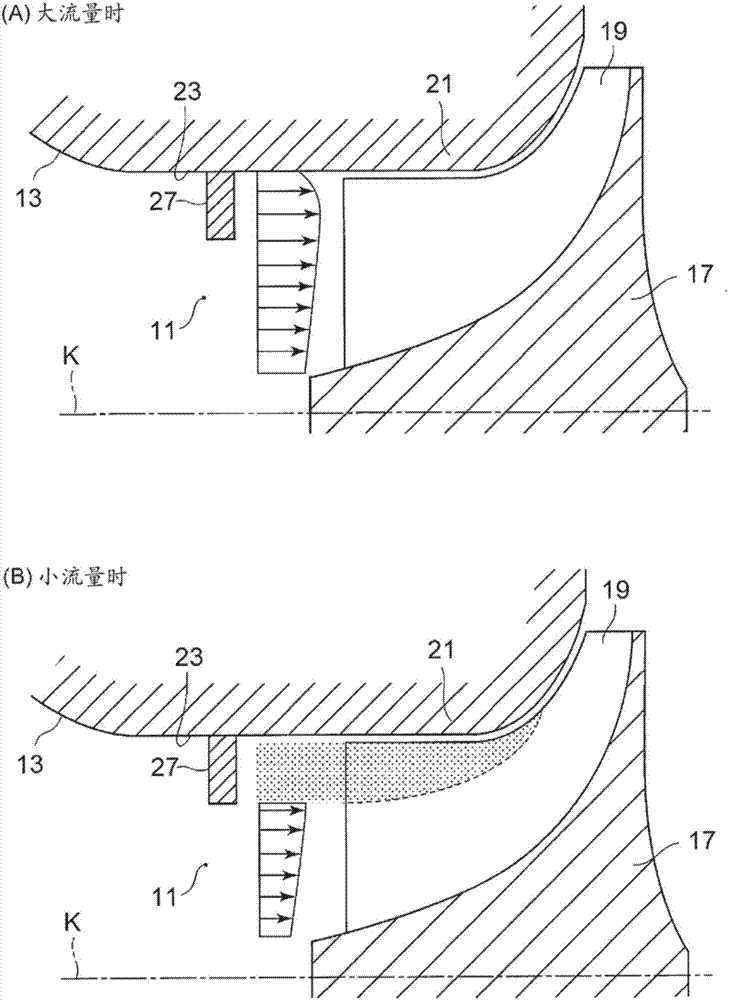

[0073] refer to Figure 1 ~ Figure 4B The first embodiment will be described.

[0074] The first embodiment is an embodiment in which the inner peripheral wall 23 of the intake passage 11 is provided with an inner peripheral resistance body 25 constituting a resistance body against the intake air flow.

[0075] The inner peripheral resistance body 25 is provided on the inner peripheral wall 23 between the air inlet 13 of the air inlet passage 11 and the vanes 19 , and is formed of an annular plate member 27 . The outer peripheral end of the plate member 27 is attached to the inner peripheral wall 23 of the intake passage 11 , and a cylindrical guide portion 29 extending in the axial direction of the intake passage 11 is attached to the inner peripheral end.

[0076] The center line of the guide part 29 coincides with the rotation axis k. By forming the guide part at the center part of the intake passage 11, the directivity of the intake air flow flowing in the center part of ...

no. 2 approach

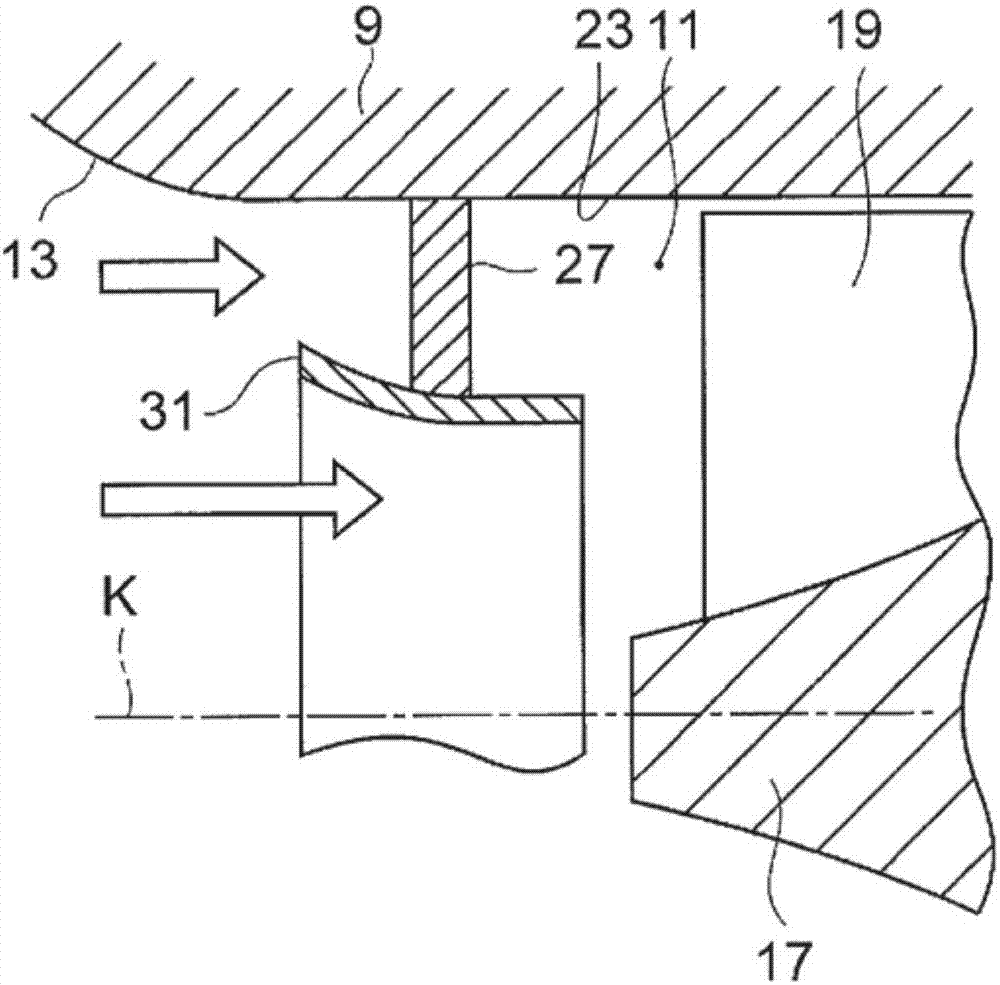

[0087] Next, refer to Figure 5 ~ Figure 7B A second embodiment will be described.

[0088] In the second embodiment, a central resistance body 41 is provided, and the central resistance body 41 is arranged at the central part of the intake passage 11 to form a resistance body against the intake air flow.

[0089] The central resistance body 41 is provided around the rotation axis k between the air inlet 13 of the air inlet passage 11 and the vane 19 , and is formed of a disc-shaped plate member 43 .

[0090]A cylindrical guide portion 45 extending in the axial direction of the intake passage 11 is attached to cover the outer periphery of the plate member 43 . The outer peripheral portion of the guide portion 45 is attached to the inner peripheral wall 23 of the intake passage 11 via struts 47 provided at four locations along the peripheral direction.

[0091] In this way, the central resistance body 41 is provided inside the guide portion 45 , and the guide portion 45 can s...

no. 3 approach

[0100] Next, refer to Figure 8 A third embodiment will be described.

[0101] In the third embodiment, the plate member 43 of the second embodiment is made into a rotating valve body 51 .

[0102] Such as Figure 8 As shown, the disc-shaped central resistance body 53 is composed of an openable and closable valve body 51. The openable and closable valve body 51 takes the radial direction of the intake passage 11 as the central axis of rotation, and is fully open along the intake air flow. Rotate between closed and fully closed to block the intake air flow.

[0103] A valve body rotation shaft 55 is connected to the rotation center axis of the valve body 51, and the valve body rotation shaft 55 penetrates the guide portion 45. Furthermore, only one support 47 is made into an internal through structure, and the valve body rotation shaft 55 connects the support 47. Or, the valve body rotating shaft 55 is provided in its place instead of a support 47, and penetrates the compres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com