Stepping type micro piezoelectric motor and working method thereof

A piezoelectric motor, stepping technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., can solve difficult problems such as motor stator displacement output performance, Achieve the effect of low production cost and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

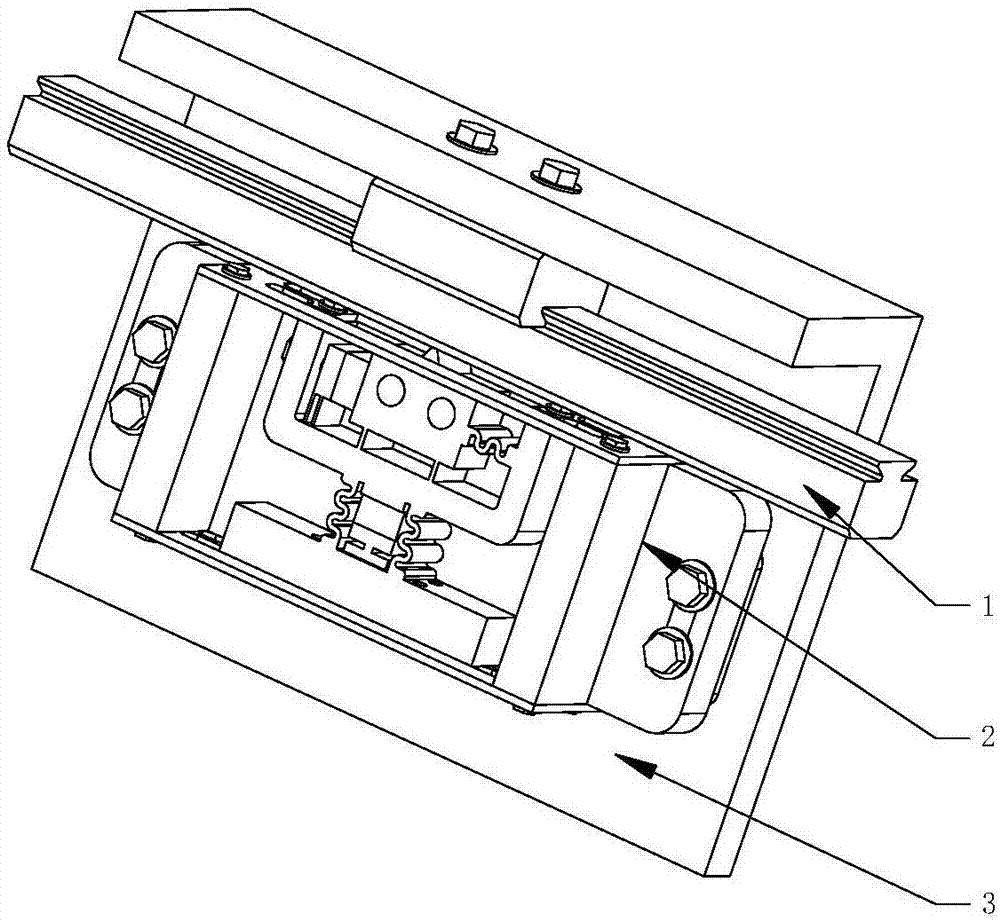

[0049] like figure 1 The stepping micro piezoelectric motor structure shown includes mover 1, stator 2 and base 3; the mover is fixed on the side plate of the base by bolts; the stator is fixed on the bottom plate of the base by bolts; The front and rear positions of the base can control the initial pressure between the stator and the mover.

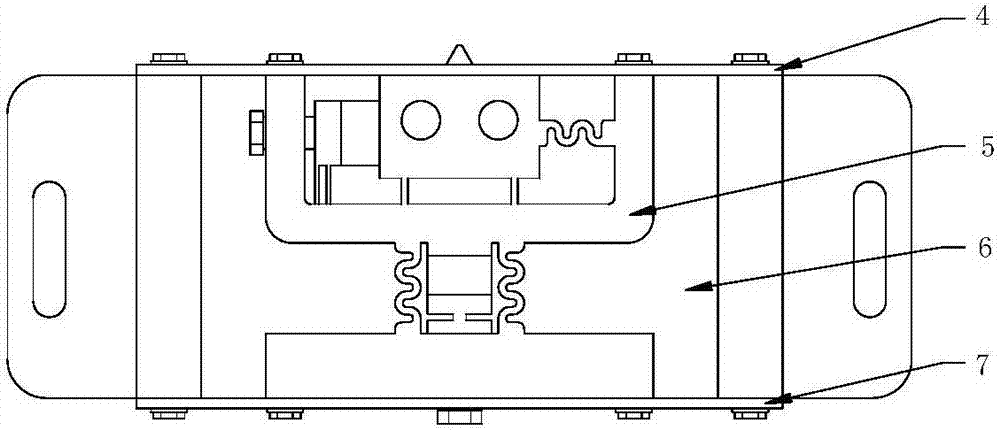

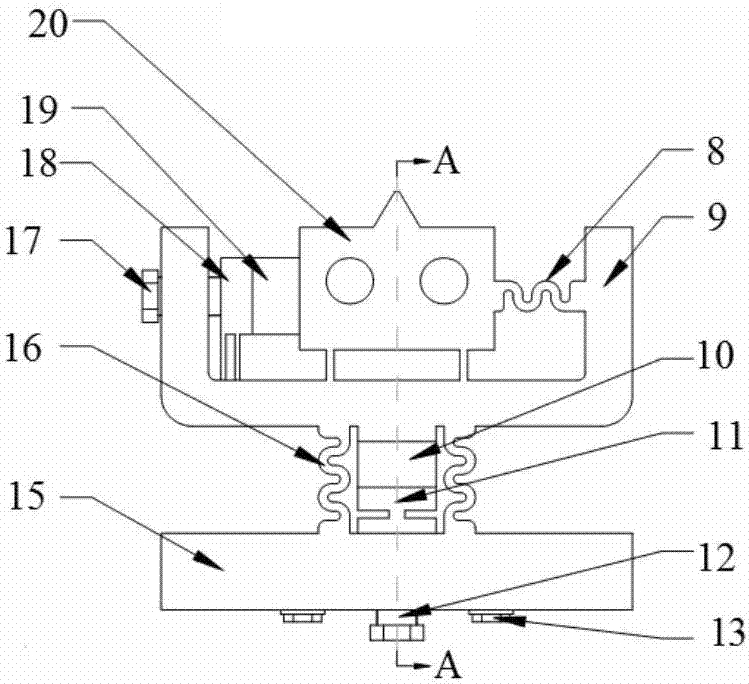

[0050] like figure 2 The stator structure of the stepping micro piezoelectric motor shown includes the driving foot 5, the support 6 and two pre-compression leaf springs; the upper and lower ends of the driving foot are respectively fixed on the square plate of the pre-compression leaf spring by bolts; the pre-compression leaf spring The ring frame is fixed on the support by bolts.

[0051] like figure 2 The clamping mechanism of the stepping micro piezoelectric motor shown is two pre-compressed leaf sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com