A differential linear piezoelectric motor and its working method

A piezoelectric motor, working method technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., can solve problems such as low positioning accuracy, achieve low production cost, The effect of long life and self-locking after power failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

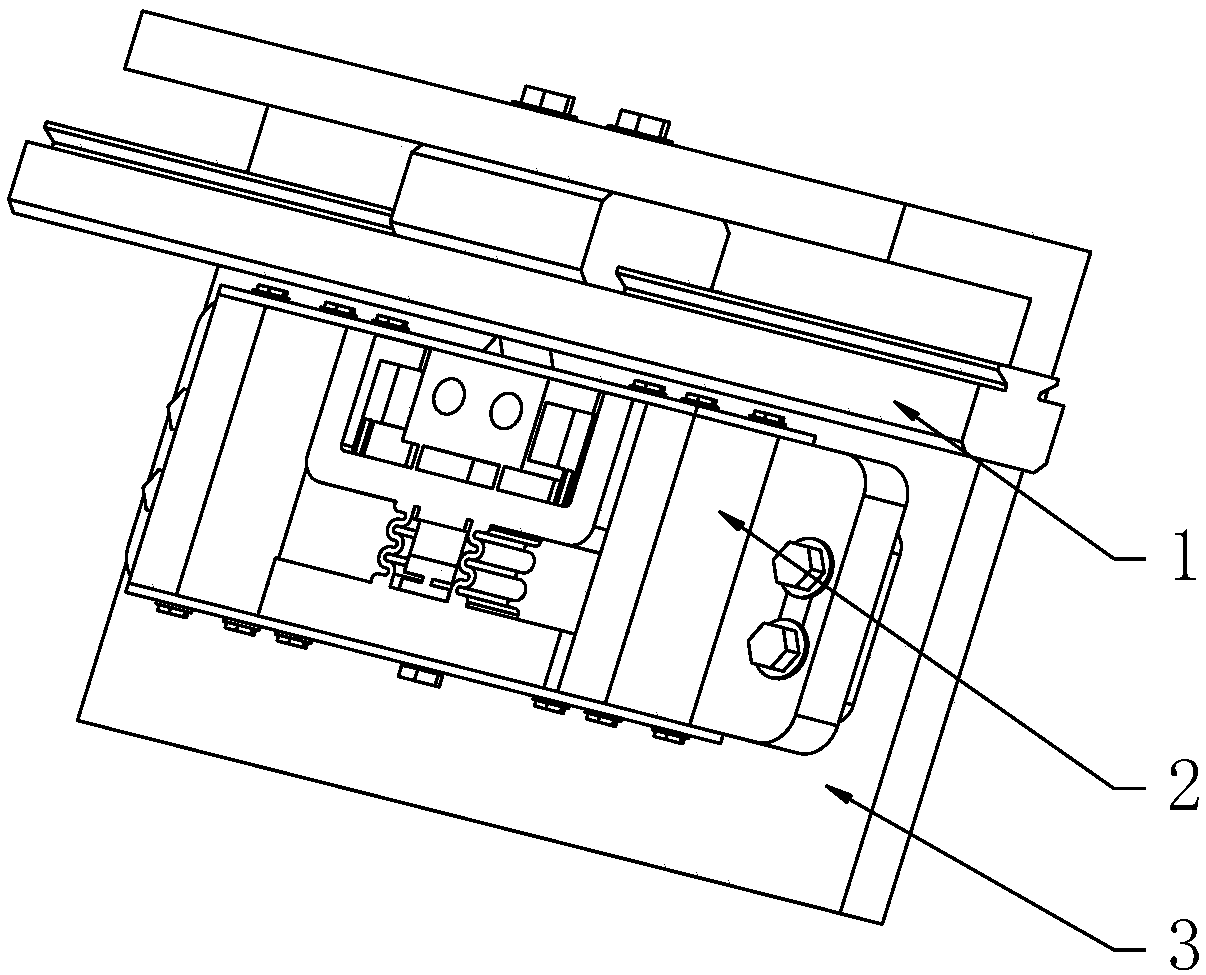

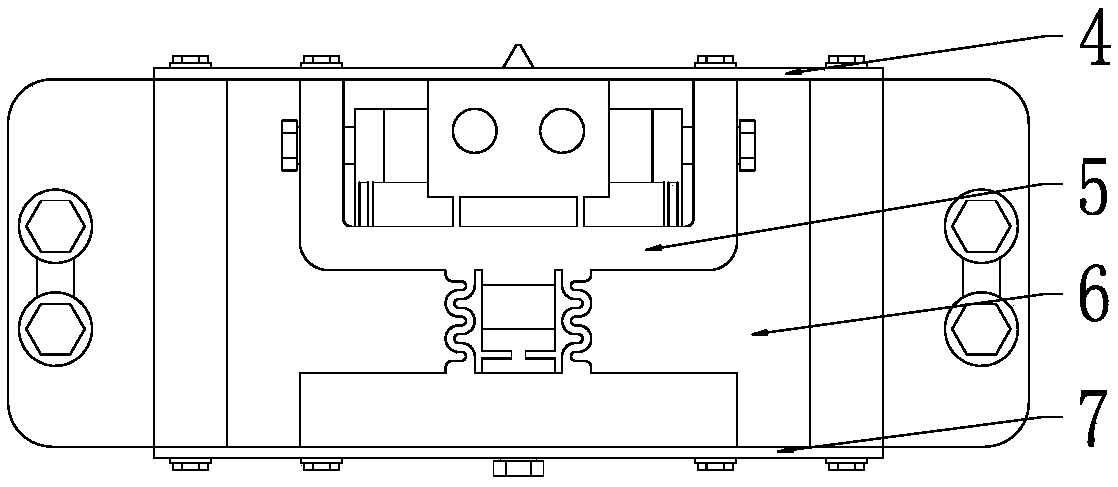

[0045] Such as figure 1 The structure of the differential linear piezoelectric motor shown includes a mover 1, a stator 2 and a base 3; the mover 1 is fixed on the side plate of the base by bolts; the stator 2 is fixed on the bottom plate of the base by bolts; by controlling the stator 2. The front and rear positions of the base can control the initial pressure between the stator 2 and the mover 1.

[0046] Such as figure 2 The elastic clamping mechanism shown is two symmetrically arranged pre-compressed leaf springs.

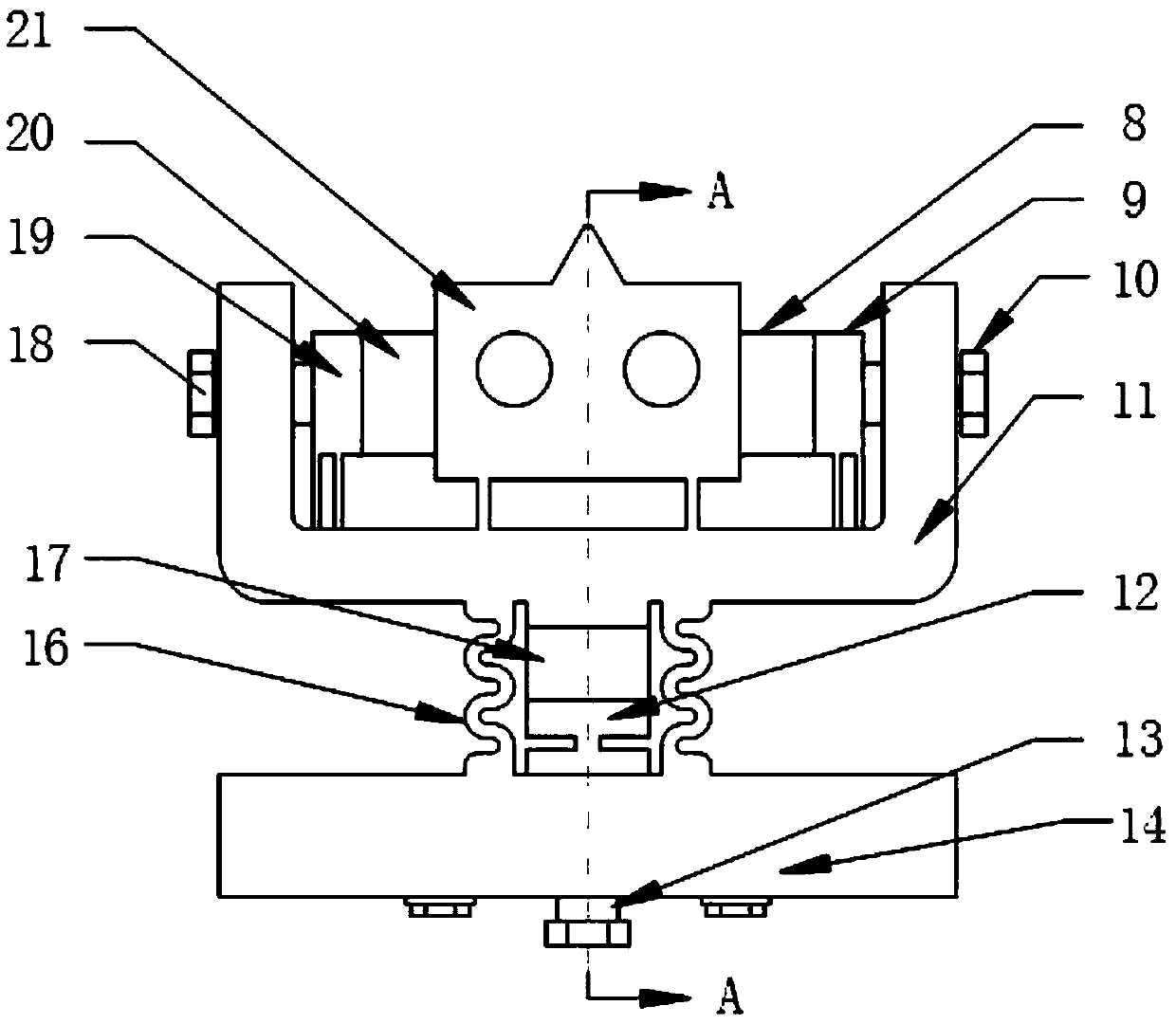

[0047] Such as Image 6 As shown, the preloaded leaf spring includes a ring frame structure, a flexible hinge and a square plate; the short side of the ring frame structure and the square plate are connected by a flexible hinge; the ring frame is provided with threaded holes, which can be fixedly connected with the support 6; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com