Centrifugal type overrunning clutch

An overrunning clutch and centrifugal technology, applied to clutches, one-way clutches, mechanical equipment, etc., can solve the time-consuming and labor-intensive problems of starting the machine, and achieve the effect of optimizing the machine starting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

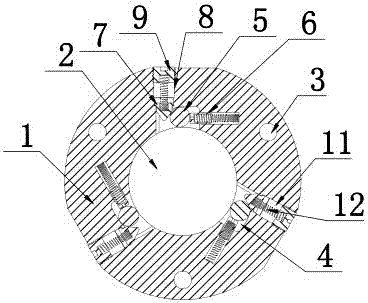

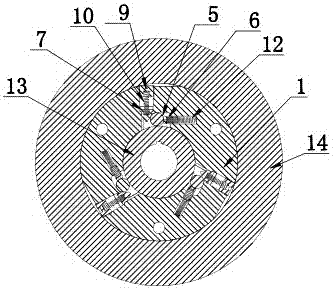

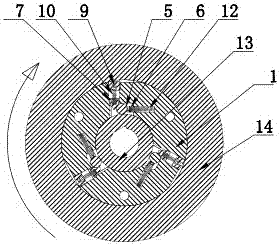

[0020] See attached figure 1 with 2 , the centrifugal overrunning clutch in the figure includes a clutch disc 1, a clutch shaft installation hole 2 located in the center of the clutch disc 1, at least three installation holes 3 evenly distributed around the clutch shaft installation hole 2, and the installation holes 3 run through the clutch disc 1 two discs; it is characterized in that:

[0021] At least three round roller installation sinks 4 are arranged at the position of the hole wall of the clutch shaft installation hole 2, and the round roller installation sinks 4 are located on the disc body of the clutch disc 1, and the round roller installation sinks 4 There are two open surfaces, the two open surfaces are two adjacent surfaces, one of the open surfaces is flush with a disk surface of the clutch disc 1, and one of the open surfaces is flush with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com