Magnetic centrifugal concentrating machine

A centrifugal concentrator and magnetic technology, applied in centrifuges, magnetic separation, solid separation, etc., can solve problems such as difficult ore unloading, low concentrate grade, difficult to popularize and apply, and achieve enhanced adaptability, flexibility and adaptability High performance, simple structure, compact and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

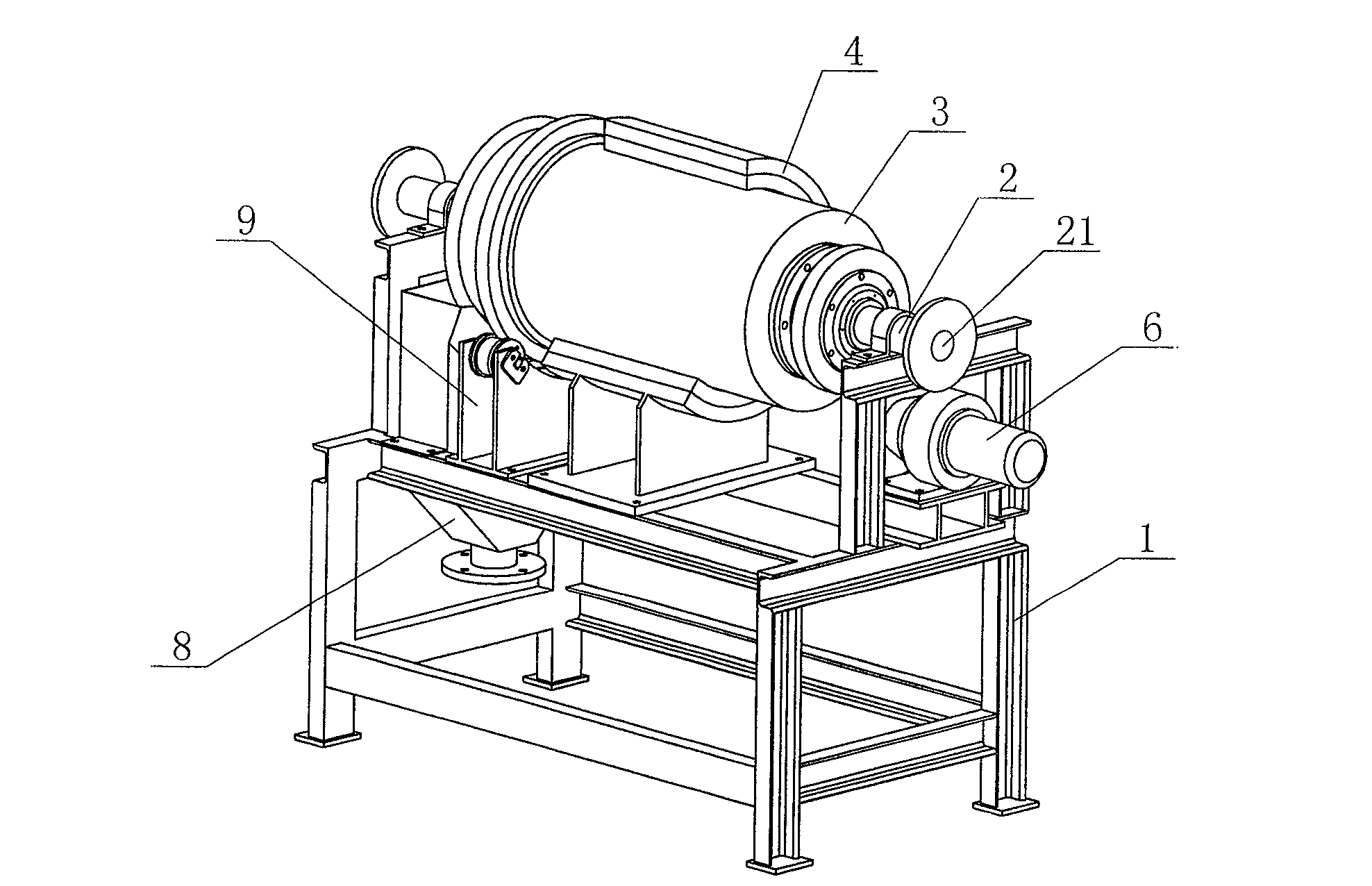

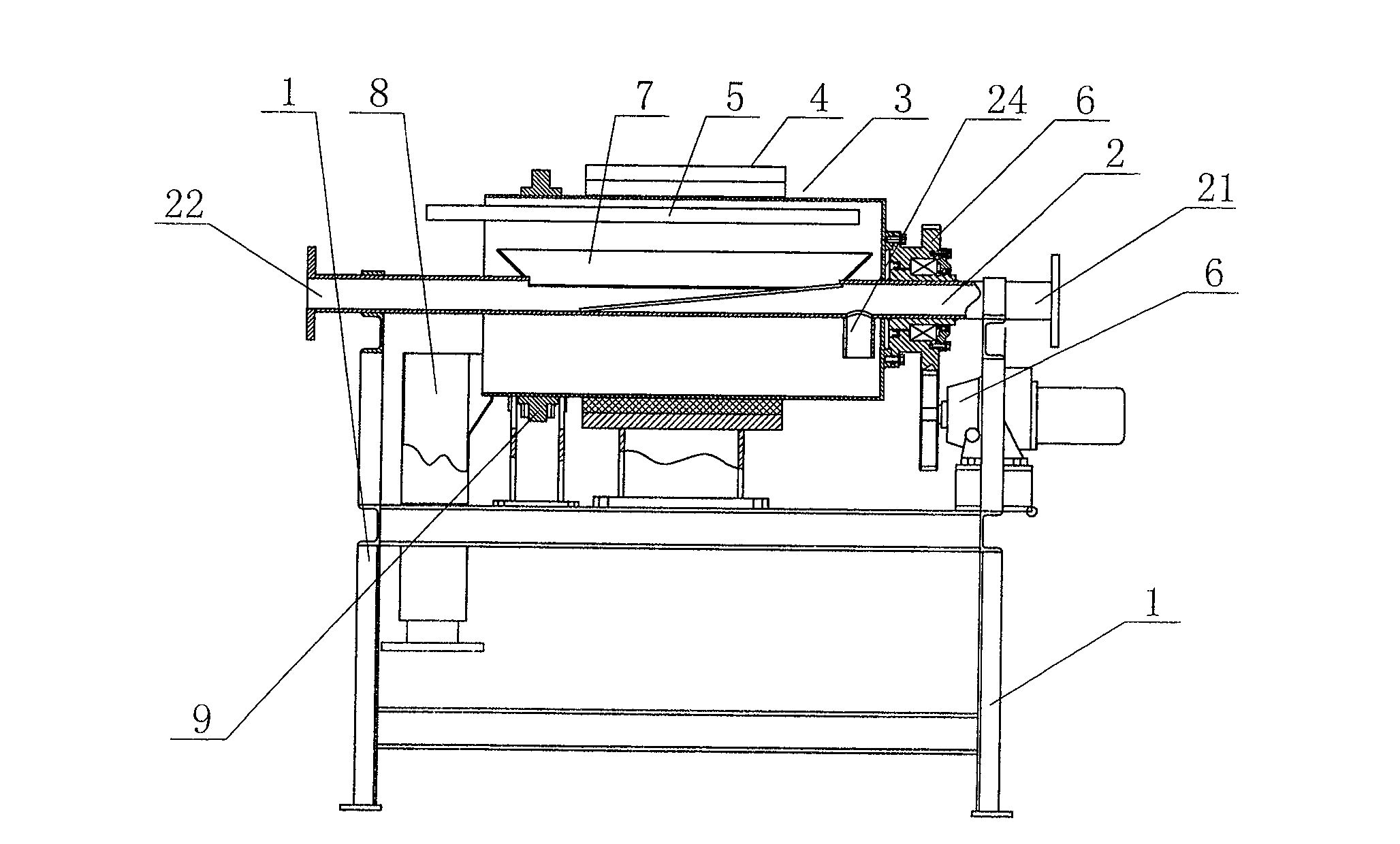

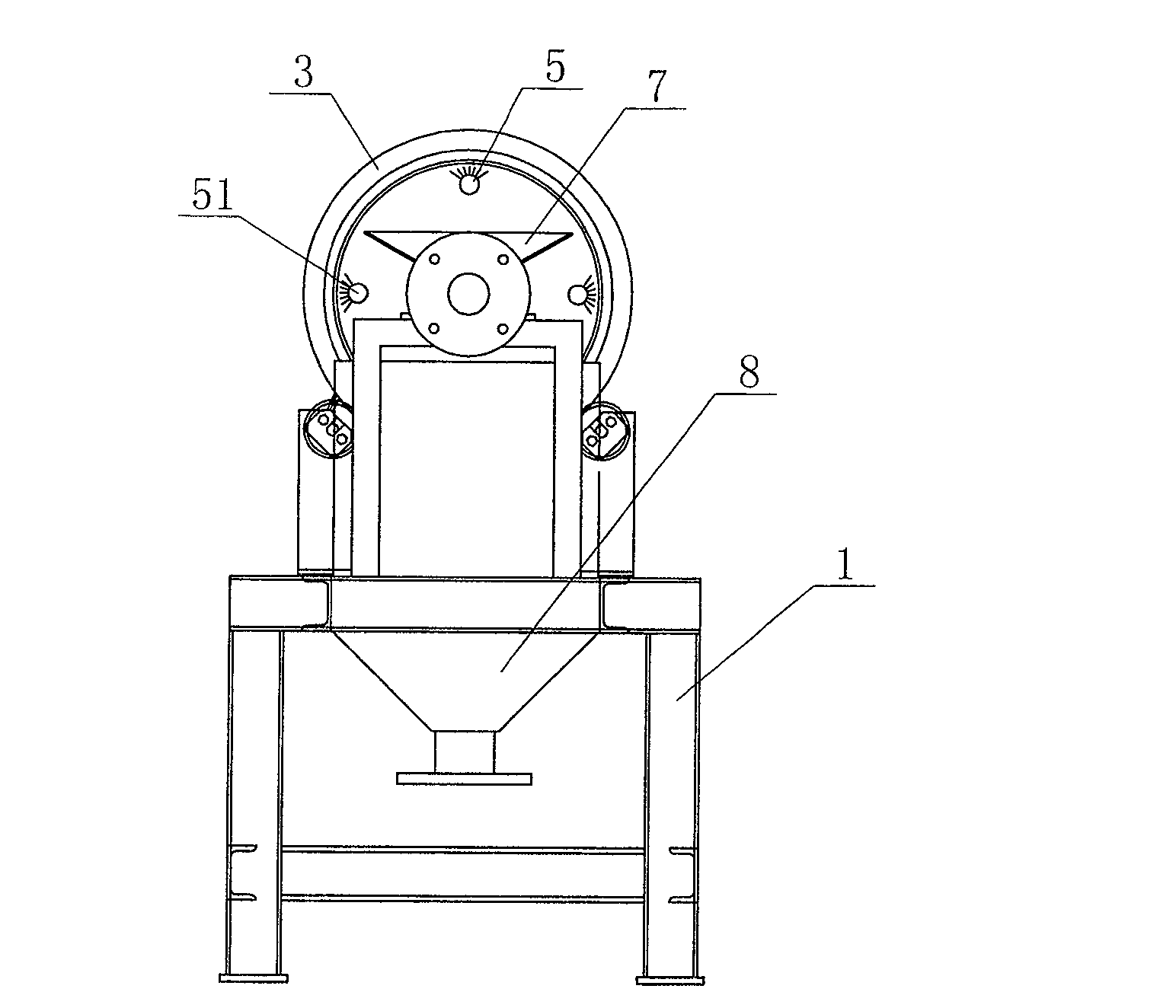

[0015] like Figure 1 ~ Figure 4 As shown, a magnetic centrifugal concentrator according to the present invention is characterized in that it includes a frame 1, a main shaft cylinder 2, a sorting cylinder 3, a half magnetic ring 4, a concentrate flushing water pipe 5, power and its transmission device 6, Wherein the main shaft cylinder 2 is supported and fixed on the frame 1, one end of which is connected with the ore hopper to form an ore feeding opening 21, and the other end is a concentrate ore outlet 22, and a partition plate 23 is arranged in the middle thereof, the said Between the partition plate 23 and the ore inlet 21, there is an ore inlet 24 that allows minerals to enter the separation cylinder 3 from the main shaft cylinder 2, and the separation cylinder 3 and the main shaft cylinder 2 are coaxially installed on the frame 1 and can rotate around the main shaft barrel 2 at a high speed driven by the power and its transmission device 6. The power and its transmissio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com