Automobile sheet metal member reference coordinate system establishing method

A technology of automobile sheet metal parts and establishment methods, applied in the field of measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

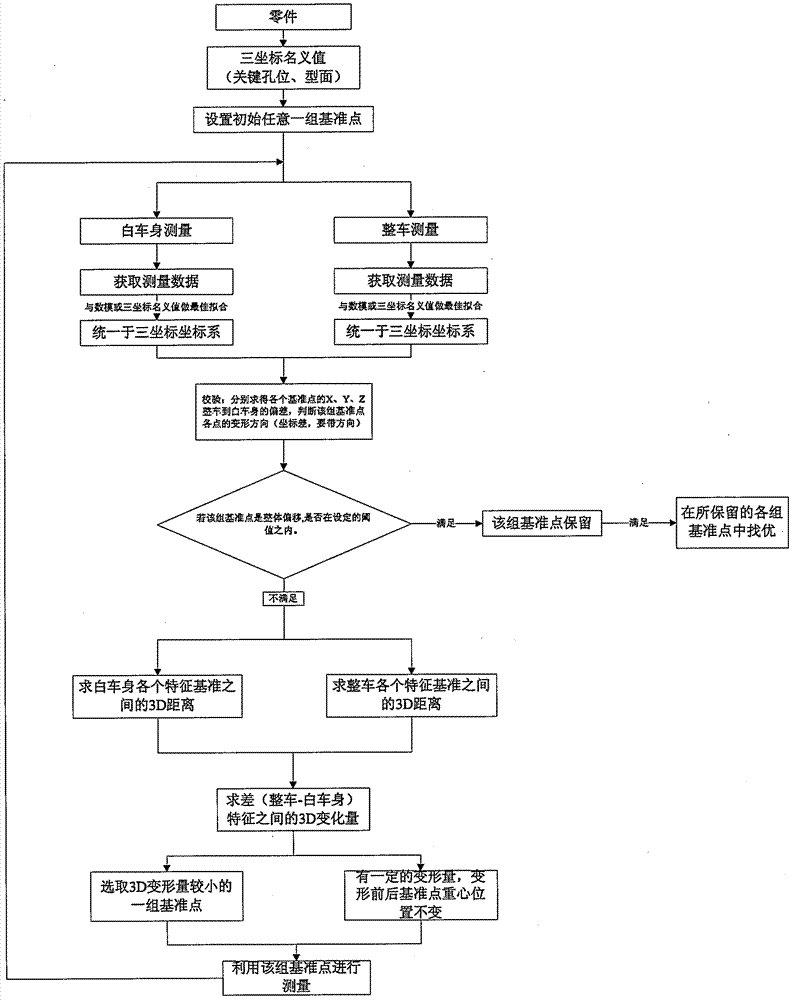

[0011] Hereinafter, the method for establishing the reference coordinate system of the automobile sheet metal part of the present invention will be described in detail with reference to the accompanying drawings.

[0012] The part has been severely deformed during several processing, and the nominal value provided by the digital model is meaningless. Under the condition that there is no part digital model, use the existing sheet metal parts, measure the key hole position or surface point data of the part through three coordinates as the nominal value, and set any initial set of reference points to unify in the three-coordinate coordinate system , to measure the parts features of the body-in-white and the vehicle state respectively;

[0013] Taking the measured value of the body-in-white as the nominal value and the measured value of the whole vehicle as the actual measured value, the measured value and the nominal value are fitted through the measured data, and the reference c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com