Heat radiation unit

A heat dissipation unit and heat dissipation part technology, applied to electrical components, modification through conduction heat transfer, cooling/ventilation/heating transformation, etc., can solve the problems of poor heat exchange efficiency, inability to have uniform temperature and remote heat dissipation at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The above-mentioned purpose of the present invention and its structural and functional characteristics will be described based on the preferred embodiments of the accompanying drawings.

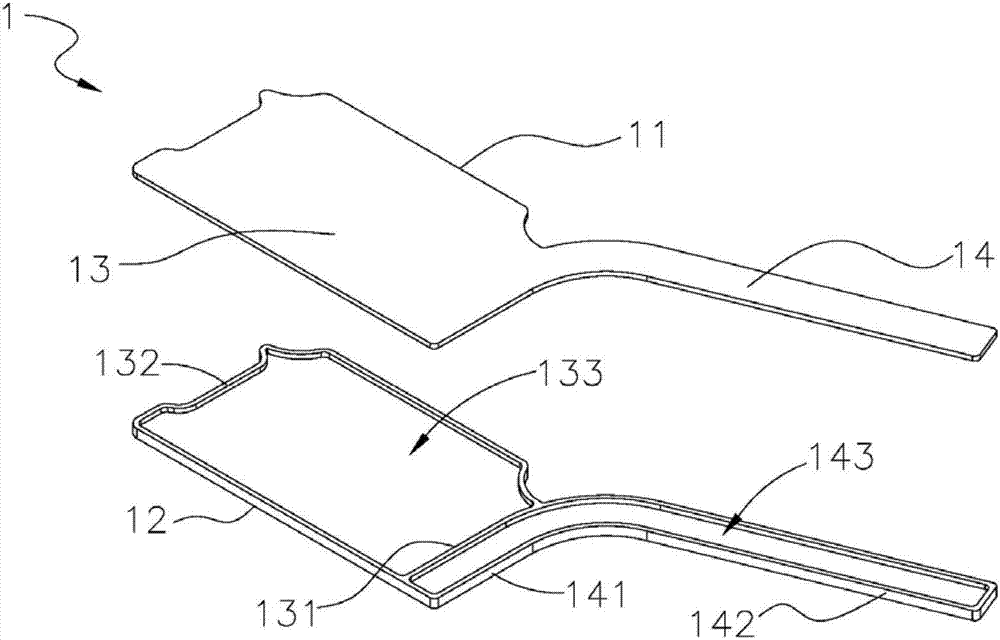

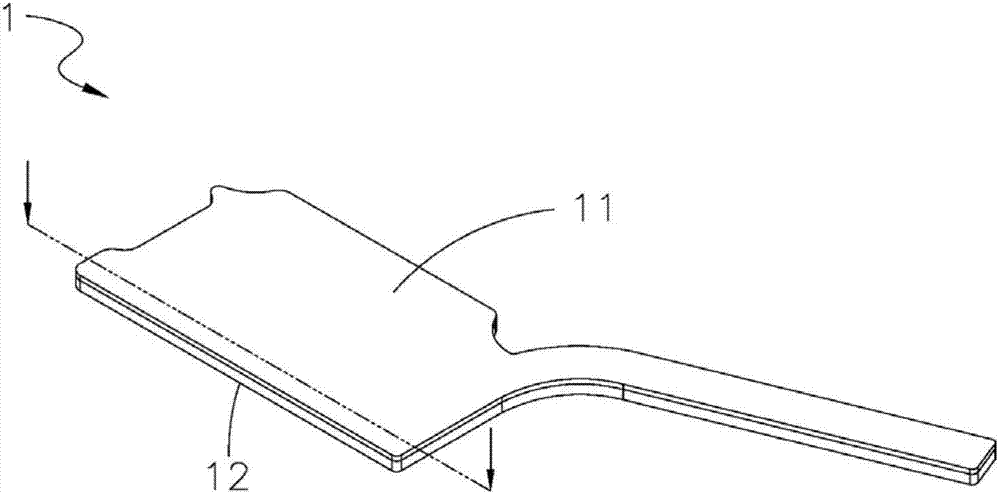

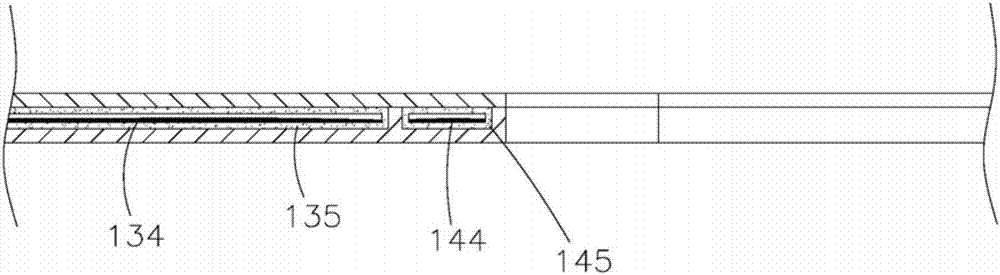

[0040] see figure 1 , 2 , 3, is the three-dimensional exploded view, the three-dimensional assembly view and the cross-sectional view of the first embodiment of the heat dissipation unit of the present invention, as shown in the figure, a heat dissipation unit includes an integrally formed body 1, and the body 1 has a first A plate body 11 is correspondingly covered with a second plate body 12. The body 1 has a first heat dissipation portion 13 connected to at least one second heat dissipation portion 14. In this embodiment, the first heat dissipation portion 13 is equivalent to a uniform temperature plate structure, but it is not limited thereto, in actual implementation, it can be other equivalents same as the vapor chamber, and the second heat dissipation part 14 is equivalent to a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com