Filter press protective cover

A technology of protective cover and filter press, applied in the direction of filtration and separation, separation methods, chemical instruments and methods, etc., can solve the problems that cannot be easily opened at any time, operation is not very convenient, and has no effect, so as to achieve convenient observation work Progress, light weight, time-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be described in detail below in conjunction with examples. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

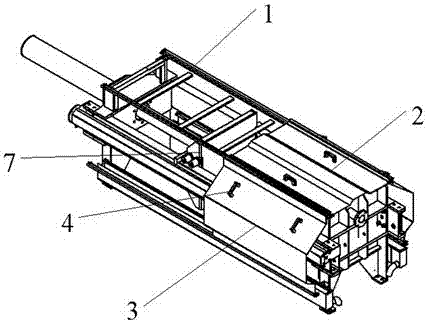

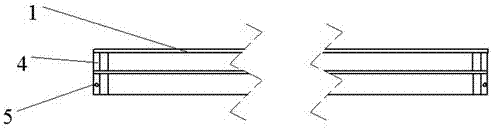

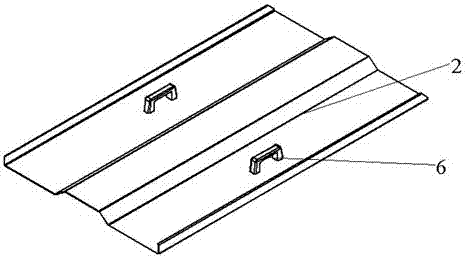

[0021] Such as Figure 1-4 The filter press protective cover in the shown embodiment includes a protective frame 1 , a top door protective cover 2 , and a side sliding door protective cover 3 . There are four protective frames 1 in total, each of which is made of stainless steel, and its shape is a combination of triangle iron type and groove type. There are screw holes 5 and limit blocks 4 at both ends. The material of limit block 4 is rubber, and the top door protective cover 2 and The integral material of side sliding door protective cover 3 is plexiglass, handle 6 is all arranged above, the length of top door protective cover 2 and side slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com