Pressing-riveting punching die

A stamping die and riveting structure technology, which is applied in the field of riveting stamping dies, can solve the problems of low production efficiency, high production cost, labor and equipment investment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

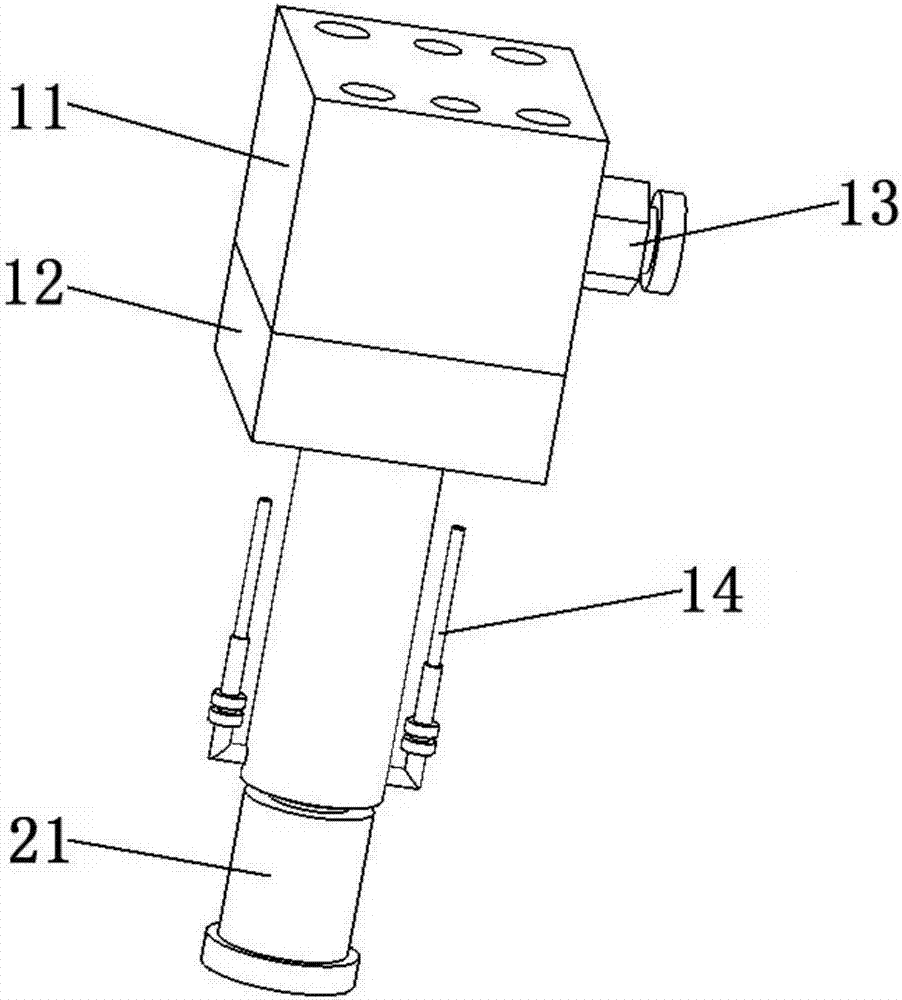

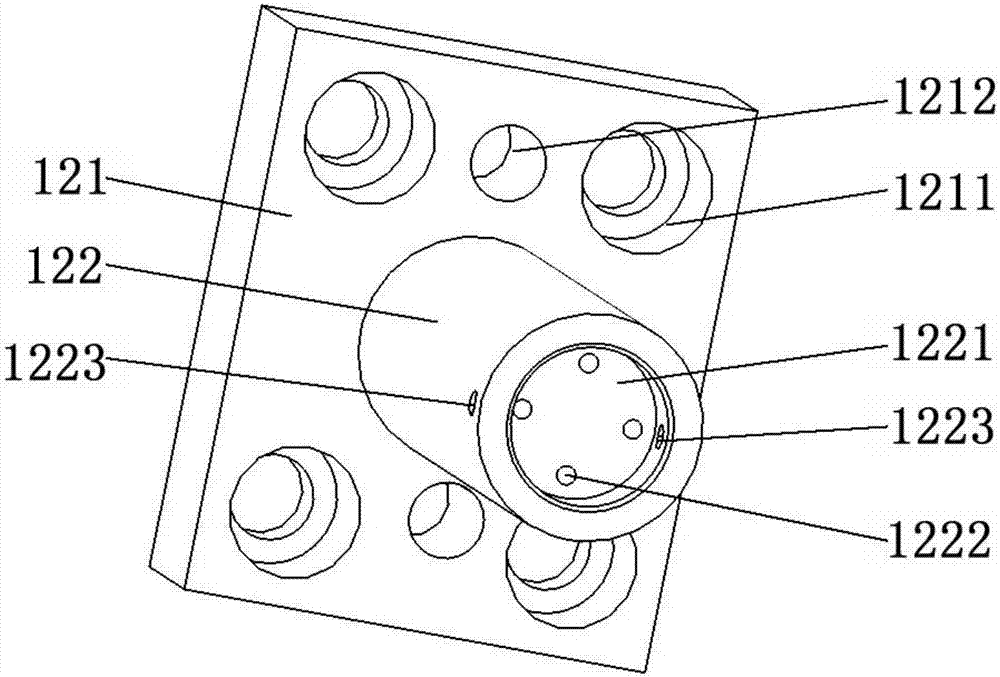

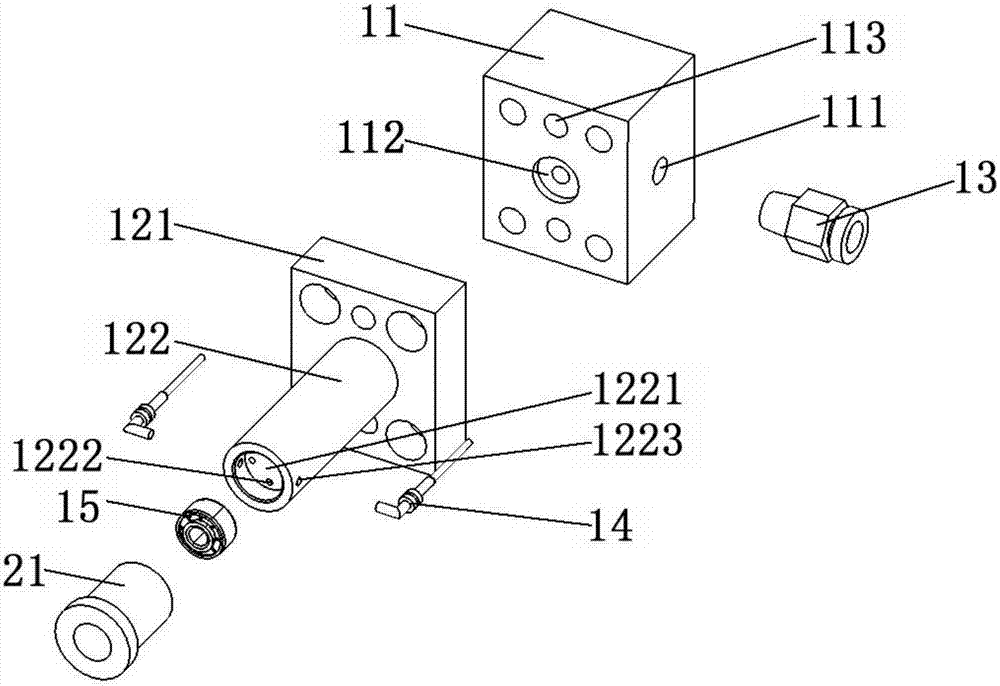

[0028] The invention discloses a riveting stamping die, see Figure 1 to Figure 3 , comprising: spacer 11, rivet fixing block 12, rivet 15 and riveting die 21, spacer 11 is fixedly arranged on the upper mold, can move with the upper mold, rivet fixing block 12 is connected with spacer 11, specifically, see figure 2 and image 3 , The rivet fixing block 12 is divided into two parts, the fixed installation part 121 and the rod part 122, these two parts are fixedly connected, of course, in a preferred embodiment, these two parts are an in...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap