Direct current ventilation and heat dissipation type electric heater

A technology of ventilation and heat dissipation, electric heater, applied in the direction of fluid heater, air heater, lighting and heating equipment, etc., can solve the problems of unsatisfactory ventilation and heat dissipation effect, poor heat dissipation effect, increased material cost, etc. and ventilation effect optimization, eliminate the limitations of production height, improve the effect of profit margins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

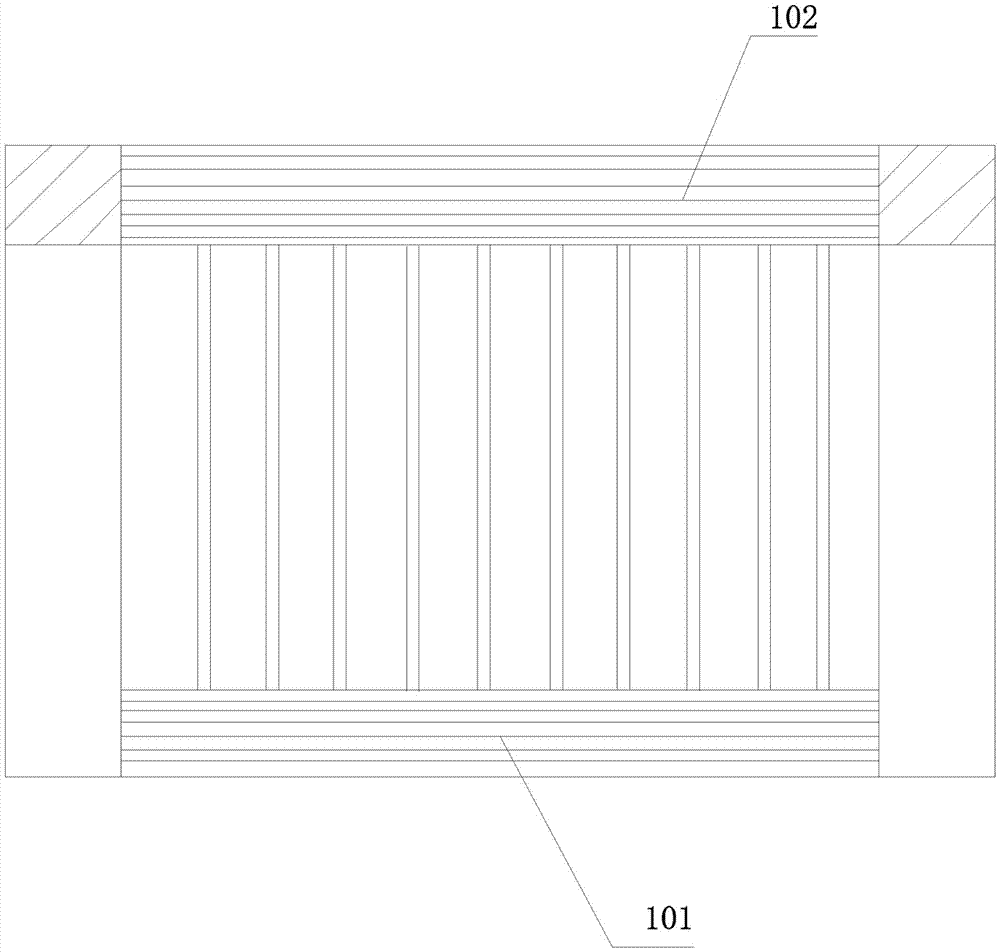

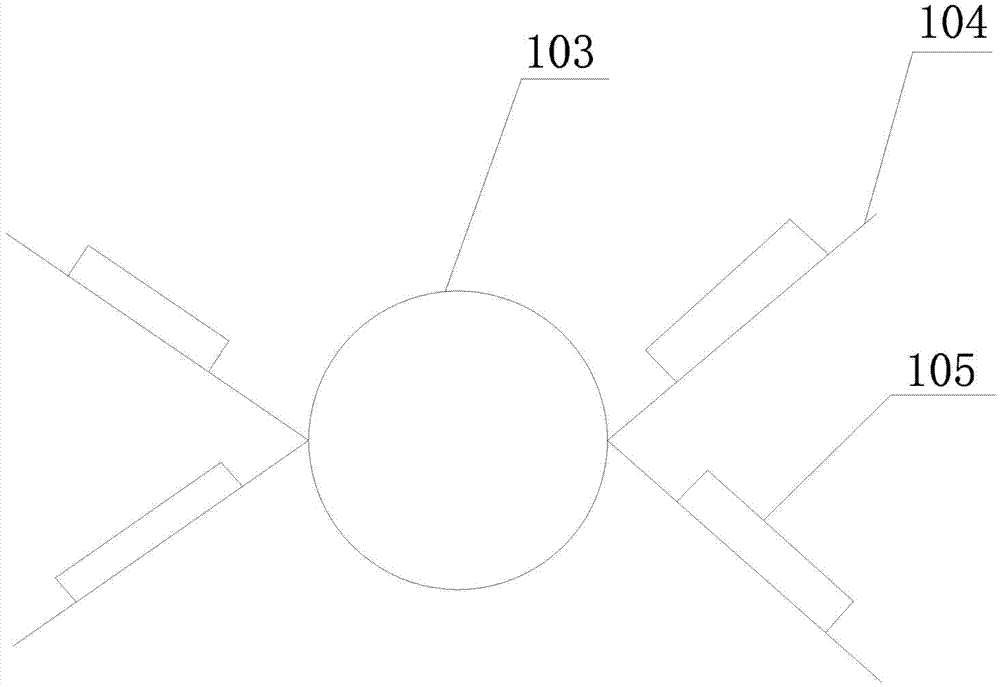

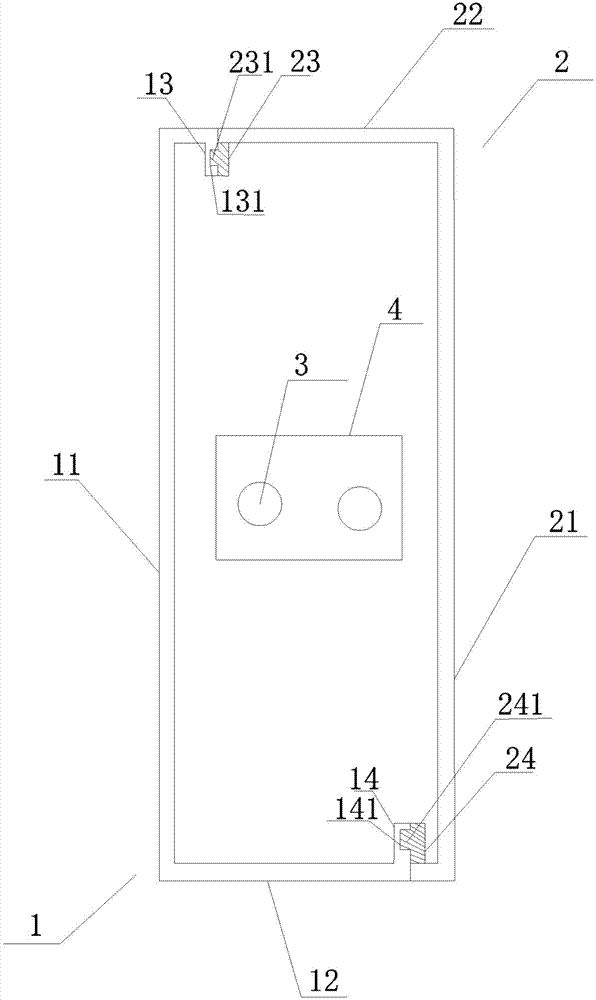

[0028] Such as Figure 3-Figure 7 As shown, the present invention provides a direct current ventilation and heat dissipation electric heater, comprising a hollow heat dissipation shell 7 and a heating pipe 3 located in the hollow heat dissipation shell 7, and a plurality of heat dissipation fins 4 uniformly arranged in a horizontal direction are arranged in the hollow heat dissipation shell 7, The heating pipe 3 runs through all the cooling fins 4, and the top and bottom surfaces of the hollow heat dissipation shell 7 are respectively provided with an upper ventilation grille window 121 and a lower ventilation grille window 221, and the lower ventilation grille window 221 is located on the upper ventilation grille window. Directly below the grille window 121, the heat sink 4 is located between the upper ventilation grille window 121 and the lower ventilation grille window 221, and both ends of the hollow heat dissipation shell 7 are welded and encapsulated by a plastic packagin...

Embodiment 2

[0030] The wind enters the hollow heat dissipation shell 7 from the lower ventilation grille window 221 at the bottom of the hollow heat dissipation shell 7 and keeps the original wind direction and passes through the heat sink 4 and the heat pipe 3 through the space between the adjacent heat sinks 4, and finally from The upper ventilation grille window 121 flows out, and the wind direction maintains a direct current mode during the whole process, and the wind force and wind speed can be maintained. The ventilation and heat dissipation performance in the hollow heat dissipation shell 7 is very good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com