Robot for monitoring warehoused materials in real time

A real-time monitoring and robotics technology, applied in the field of robotics, can solve the problems of loss, expanding the scope of detection and monitoring, deep storage grain deterioration and prone to accidents, etc., and achieve the effect of wide application range and expanding the scope of detection and monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

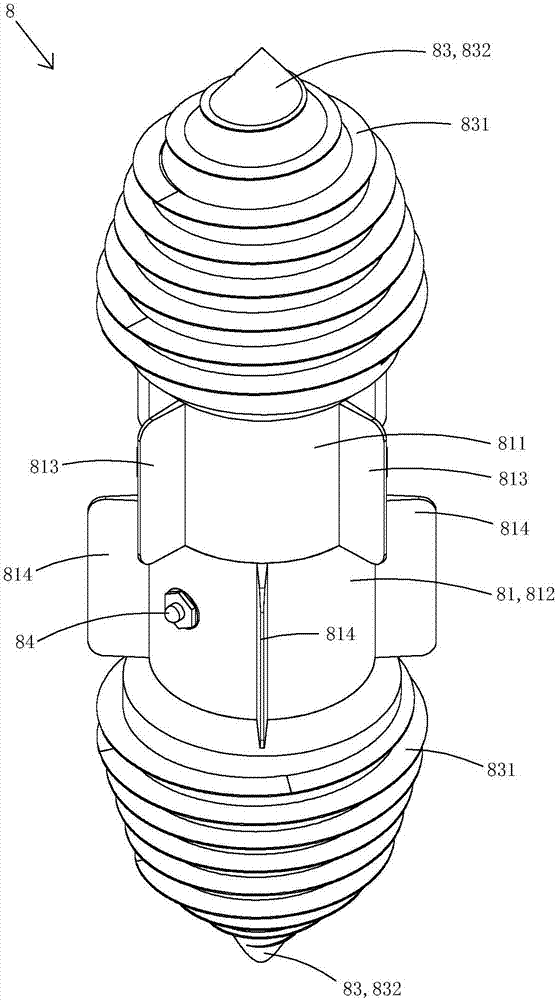

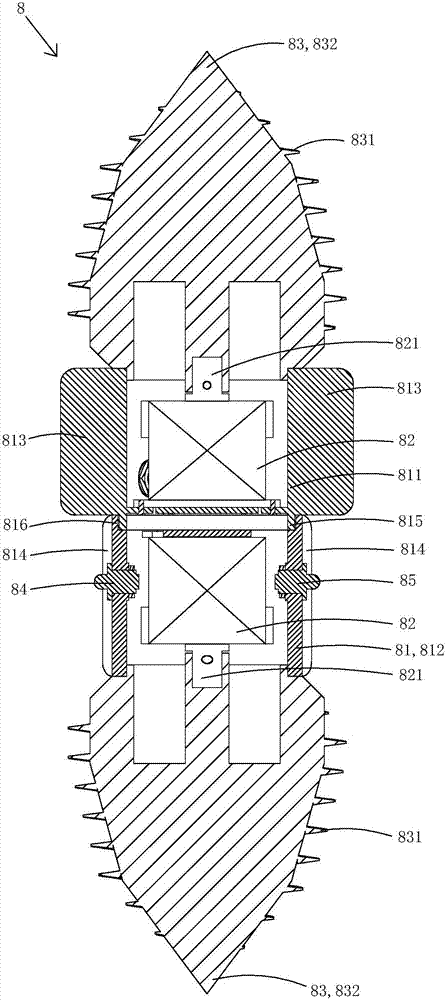

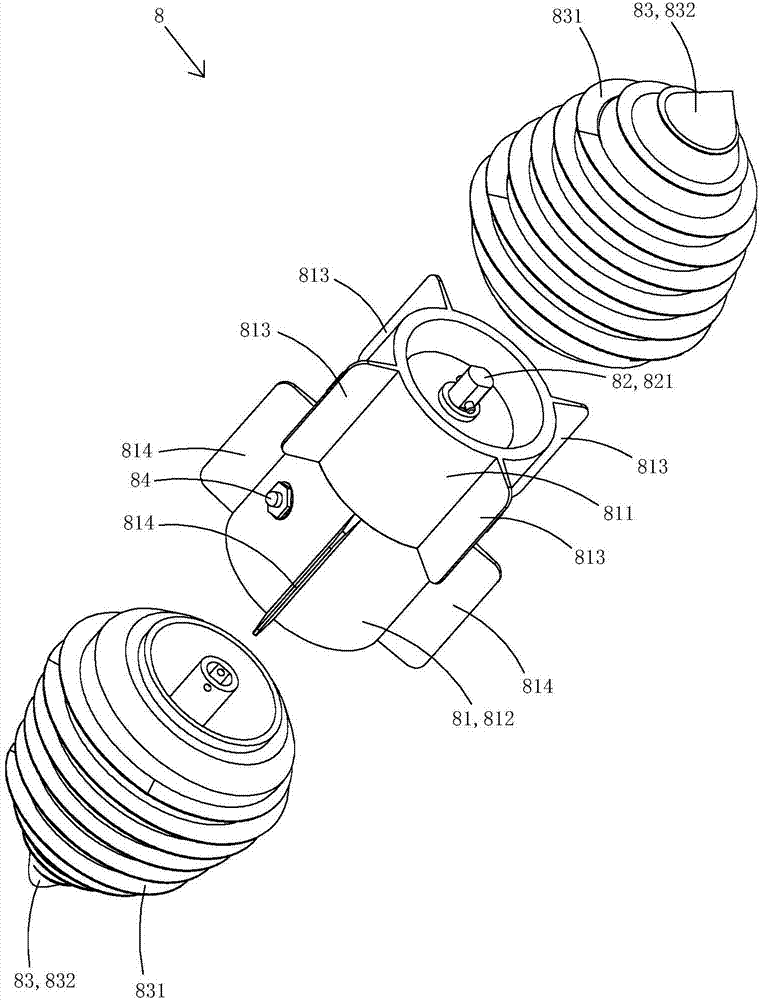

[0021] Figure 1 to Figure 3 One specific embodiment of the invention is shown.

[0022] This embodiment is a robot for real-time monitoring of storage materials, see Figure 1 to Figure 3 As shown, the robot 8 includes a cylinder shell 81, two drive motors 82 fixedly arranged at both ends of the cylinder shell, and a drilling cap 83 fixedly disposed on the output shaft 821 of the drive motor. The motor drives the drilling cap and the helical plate to rotate synchronously back and forth; each drilling cap is provided with a conical tip 832 for reducing resistance. The spiral plate is arranged on the peripheral wall of the drilling cap along the helical direction, and the spiral plate obtains thrust to advance or retreat by stirring the material in its slot.

[0023] The spiral plate can be made of metal or plastic material, preferably metal.

[0024] The shell comprises a circular upper half pipe 811 and a circular lower half pipe 812, each of the upper half pipe and the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com