Exploring robot for warehouse

A robot and warehouse technology, applied in the field of robots, can solve problems such as loss, expanding the scope of detection and monitoring, deep storage grain deterioration and prone to accidents, etc., and achieve the effect of wide application range and expanding the scope of detection and monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

[0027] Figure 1 to Figure 5 A first embodiment of the invention is shown.

[0028] The present embodiment is a kind of detection robot for warehouse, see Figure 1 to Figure 5 As shown, the warehouse inspection robot 6 includes a cylindrical shell 61, a traveling roller tube 62 rotatably arranged on the outer wall of the cylindrical shell, a transmission gear 63 fixedly arranged on the traveling roller tube, and a driving motor 64 for driving the transmission gear to rotate.

[0029] The transmission gear is fixedly arranged on the inner wall of the traveling roller tube, the inner peripheral wall of the transmission gear is provided with a transmission tooth portion 631, and the driving motor is provided with a driving gear 641, which is adapted to the transmission tooth portion of the transmission gear. In this embodiment, the number of driving motors is two. In this embodiment, the traveling roller tube and the transmission gear are an integral part. In practice, it is e...

Embodiment 2)

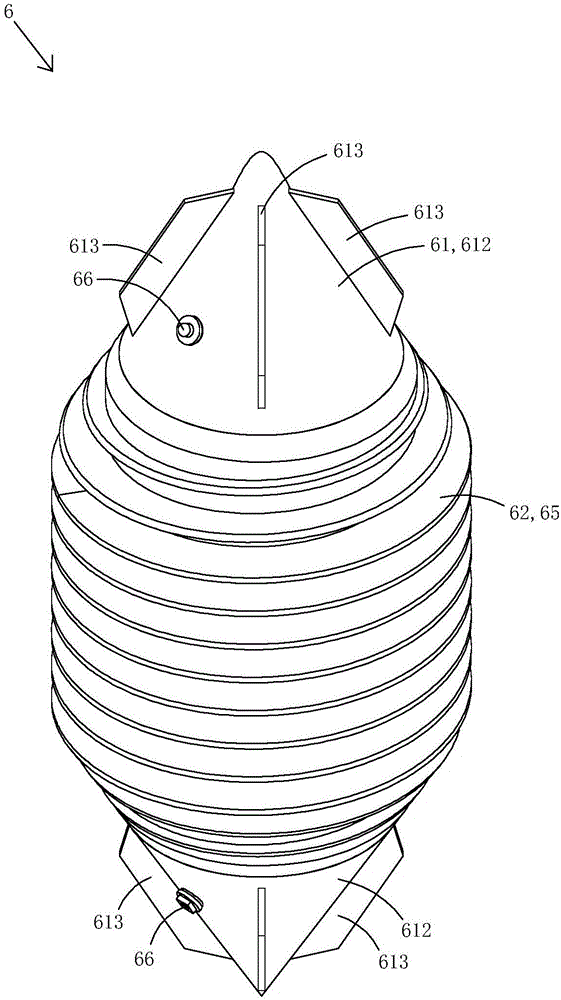

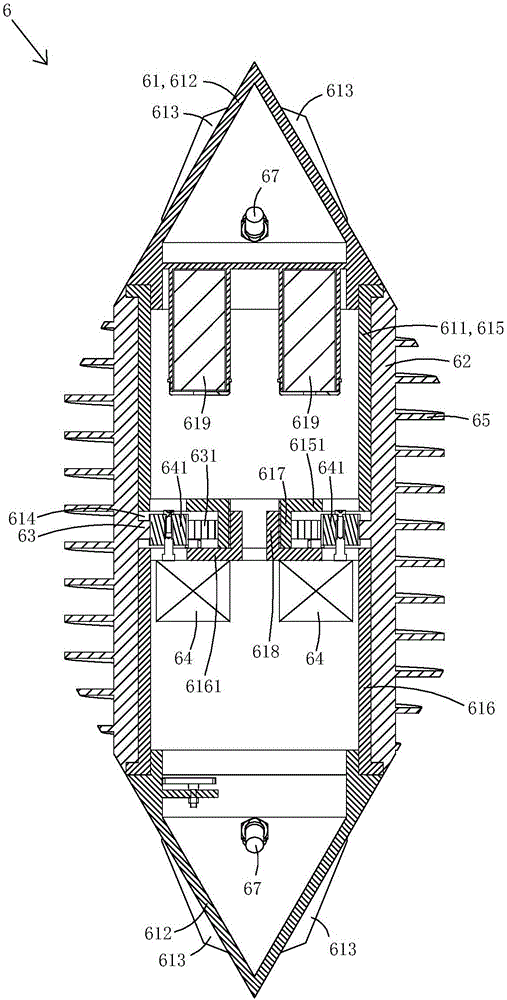

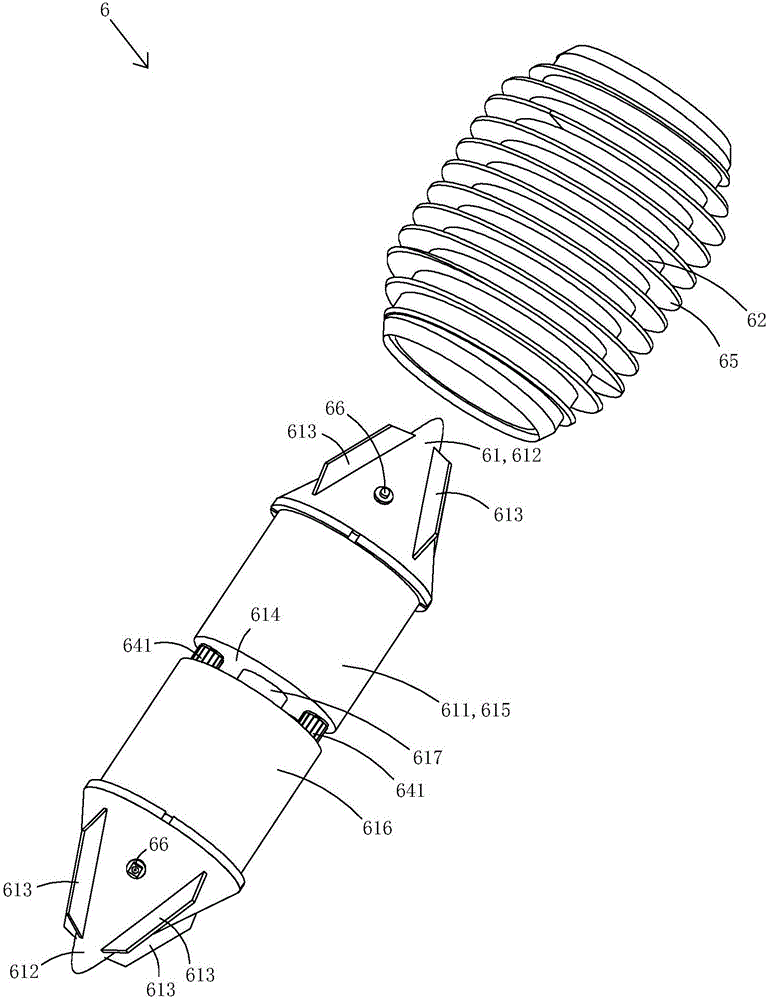

[0041] Figure 6 to Figure 9 A second embodiment of the invention is shown.

[0042] This embodiment is basically the same as Embodiment 1, the difference is: see Figure 6 to Figure 9As shown, four helical grooves 68 are arranged on the outer wall of the rolling tube, the width of each helical groove is greater than the width of the helical groove formed by the helical push plate, and the depth of each helical groove is greater than the depth of the helical groove formed by the helical push plate ; In practice, the width of each helical groove is two to six times the width of the helical groove formed by the helical push plate, and the present embodiment is three times.

[0043] In this embodiment, each helical groove penetrates the helical push plate along the direction from one end of the traveling roller tube to the other end, and each helical groove also penetrates the helical push plate along the radial direction of the traveling roller tube, but does not penetrate thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com