Two-speed clutch with reverse clutch function

A clutch device and clutch technology, applied in the direction of transmission, gear transmission, transmission control, etc., can solve the problems of linearizable control, high power transmission life, hindered cost reduction, and increased control system complexity. Achieve the effect of light weight, low noise and prolong engine life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

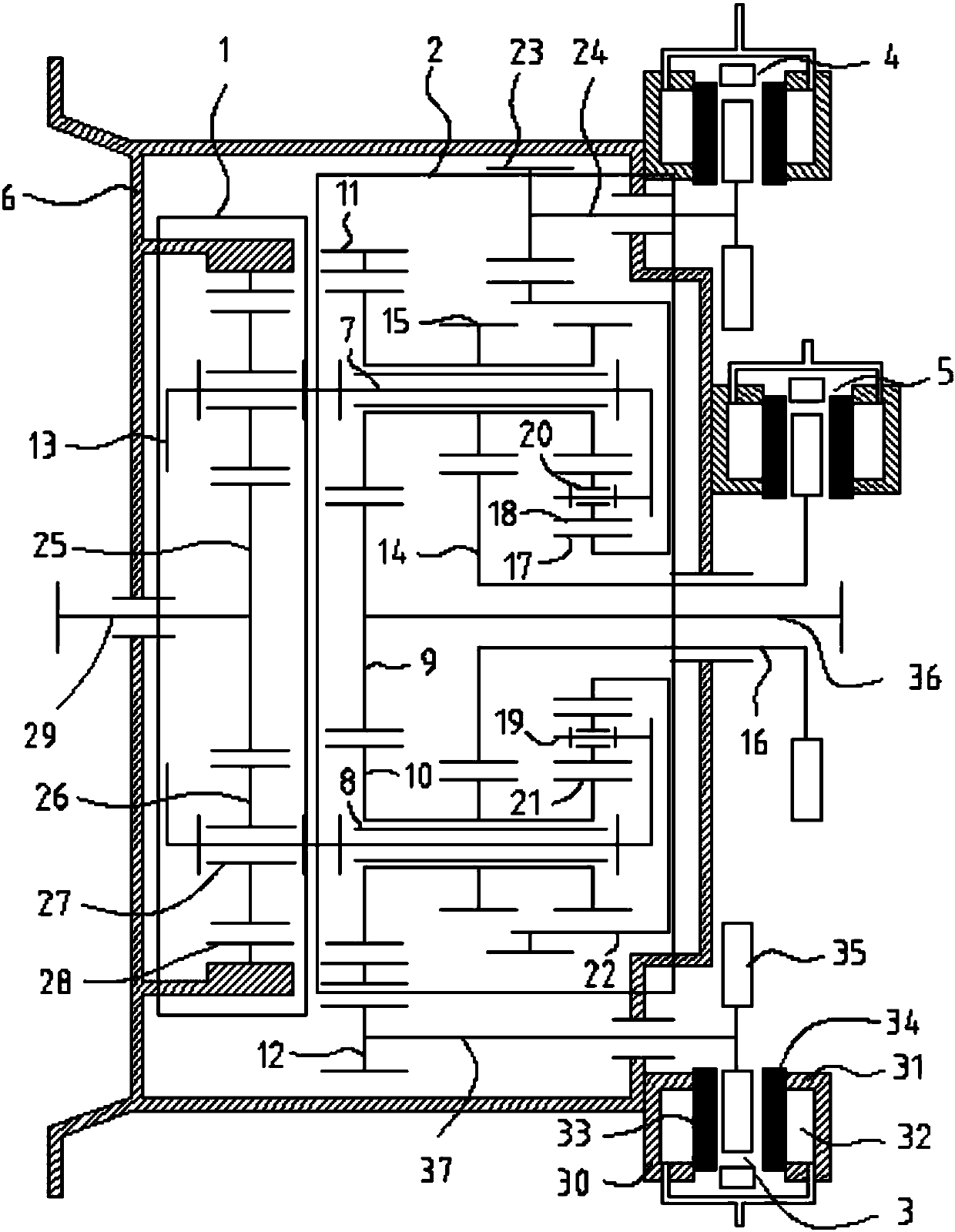

[0030] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings. It should be noted here that the descriptions of these embodiments are used to help understand the present invention, but are not intended to limit the present invention. In addition, the technical features involved in the various embodiments of the present invention described below may be combined with each other as long as they do not constitute a conflict with each other.

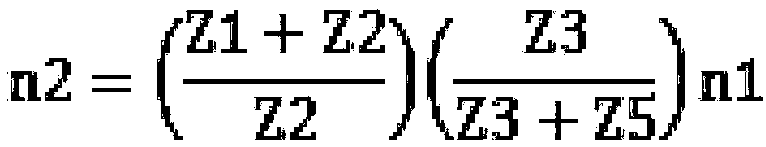

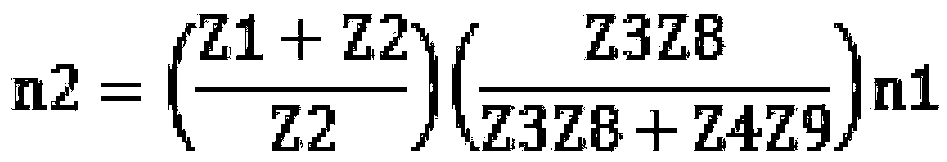

[0031] as attached figure 1 As shown, the two-speed clutch device with reverse clutch function includes input planetary mechanism 1, output planetary mechanism 2, high-speed brake disc 3, low-speed brake disc 4, reverse clutch brake disc 5, and box body 6 . In the specific implementation process, the input planetary mechanism 1 and the output planetary mechanism 2 are coaxially installed in the box body 6 . The output planetary mechanism 2 is respectively connected wi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap