Pullback calculation method and device based on stepped hole

A computing method and technology of computing device, applied in design optimization/simulation, special data processing applications, etc., can solve problems such as pipeline deformation and damage, seldom research on special construction conditions, failure of crossing engineering, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

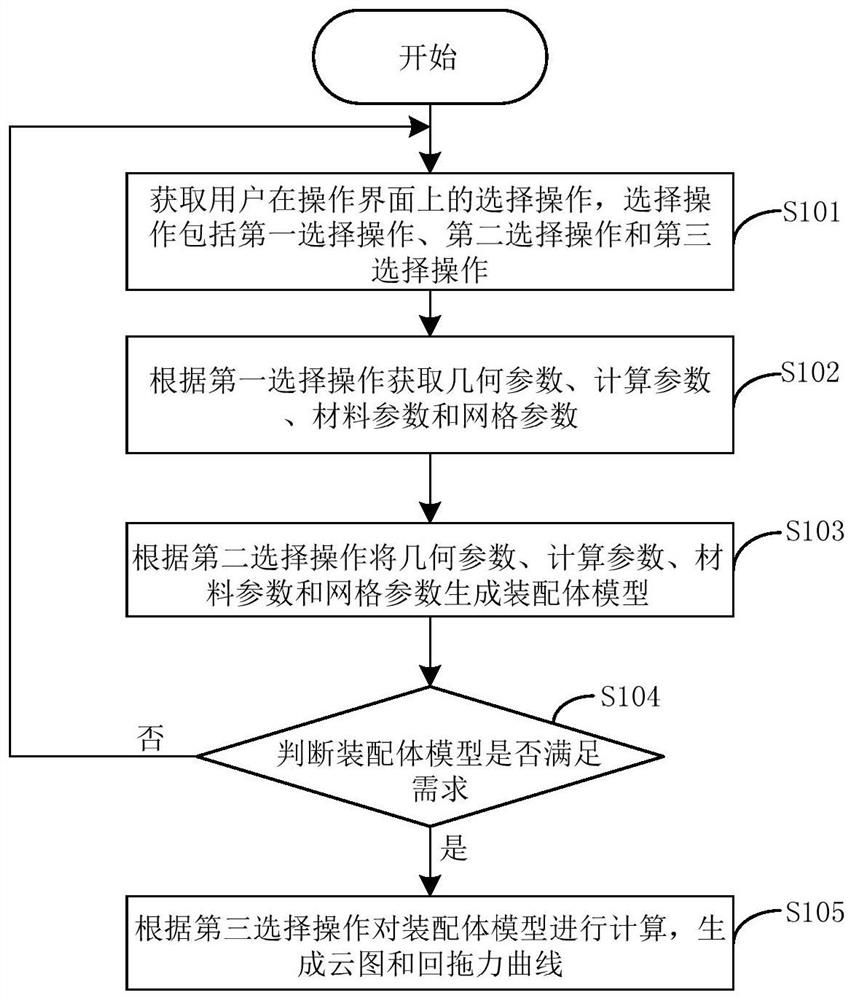

[0045] figure 1It is a flow chart of the calculation method for pullback based on stepped holes provided by the embodiment of the present invention.

[0046] refer to figure 1 , the method includes the following steps:

[0047] Step S101, acquiring the user's selection operation on the operation interface, the selection operation includes a first selection operation, a second selection operation and a third selection operation;

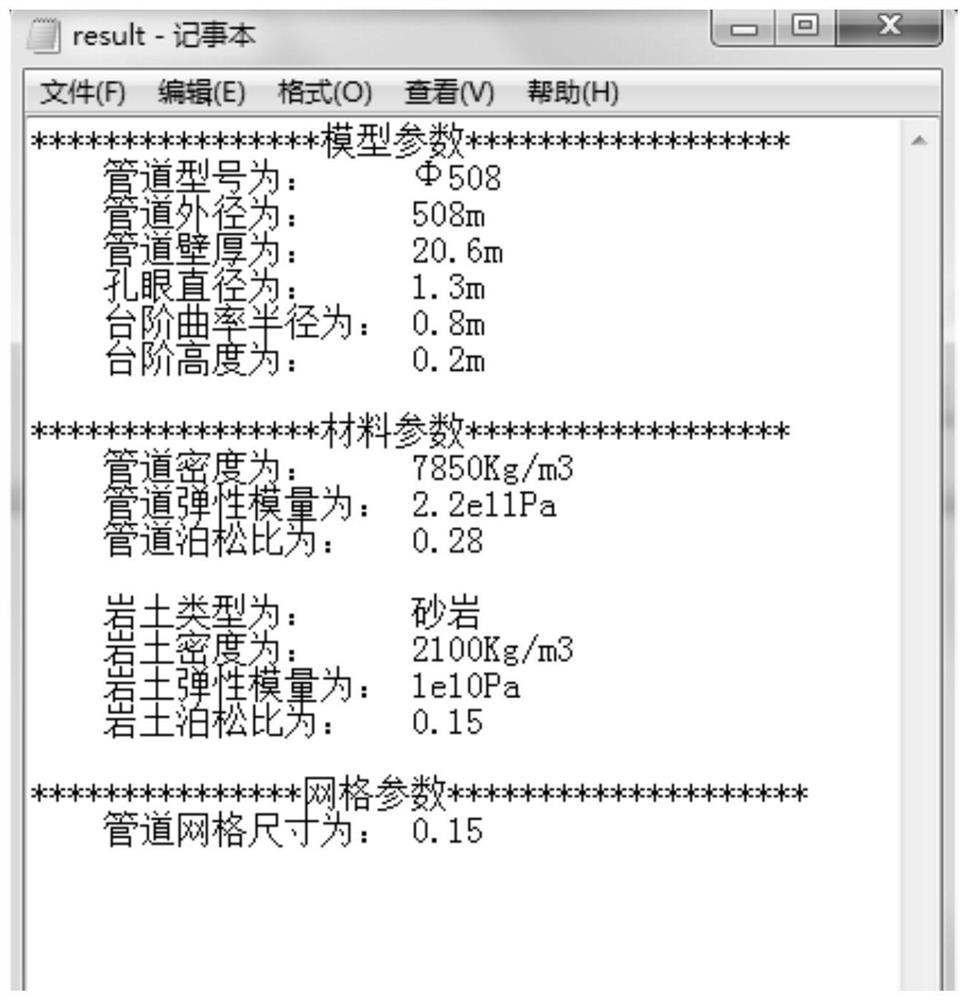

[0048] Step S102, acquiring geometric parameters, calculation parameters, material parameters and mesh parameters according to the first selection operation;

[0049] Step S103, generating an assembly model from the geometric parameters, calculation parameters, material parameters and mesh parameters according to the second selection operation;

[0050] Step S104, judging whether the assembly model meets the requirement, if it meets the requirement, execute step S105; if not, execute step S101;

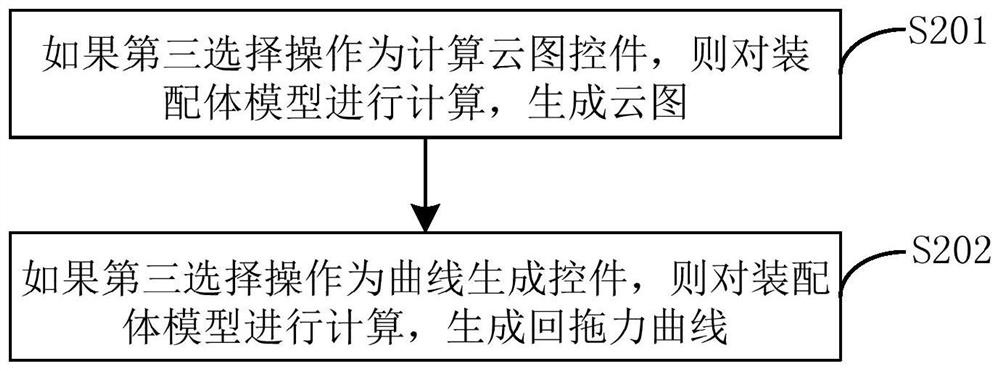

[0051] Step S105, calculate the assembly model acco...

Embodiment 2

[0069] Figure 4 It is a schematic diagram of the pullback calculation device based on stepped holes provided in Embodiment 2 of the present invention.

[0070] refer to Figure 4 , the device includes a selection operation acquisition unit 10 , a parameter acquisition unit 20 , a generation unit 30 , a judgment unit 40 and a calculation unit 50 .

[0071] A selection operation acquiring unit 10, configured to acquire a user's selection operation on the operation interface, where the selection operation includes a first selection operation, a second selection operation, and a third selection operation;

[0072] A parameter acquisition unit 20, configured to acquire geometric parameters, calculation parameters, material parameters and grid parameters according to the first selection operation;

[0073] A generating unit 30, configured to generate an assembly model from the geometric parameters, calculation parameters, material parameters and grid parameters according to the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com