Mold provided with disengagement structure for undercut on side wall of inner hole

An inner hole and undercut technology, which is applied in the field of molds with undercut exit structures, can solve the problem of not having broken lines and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

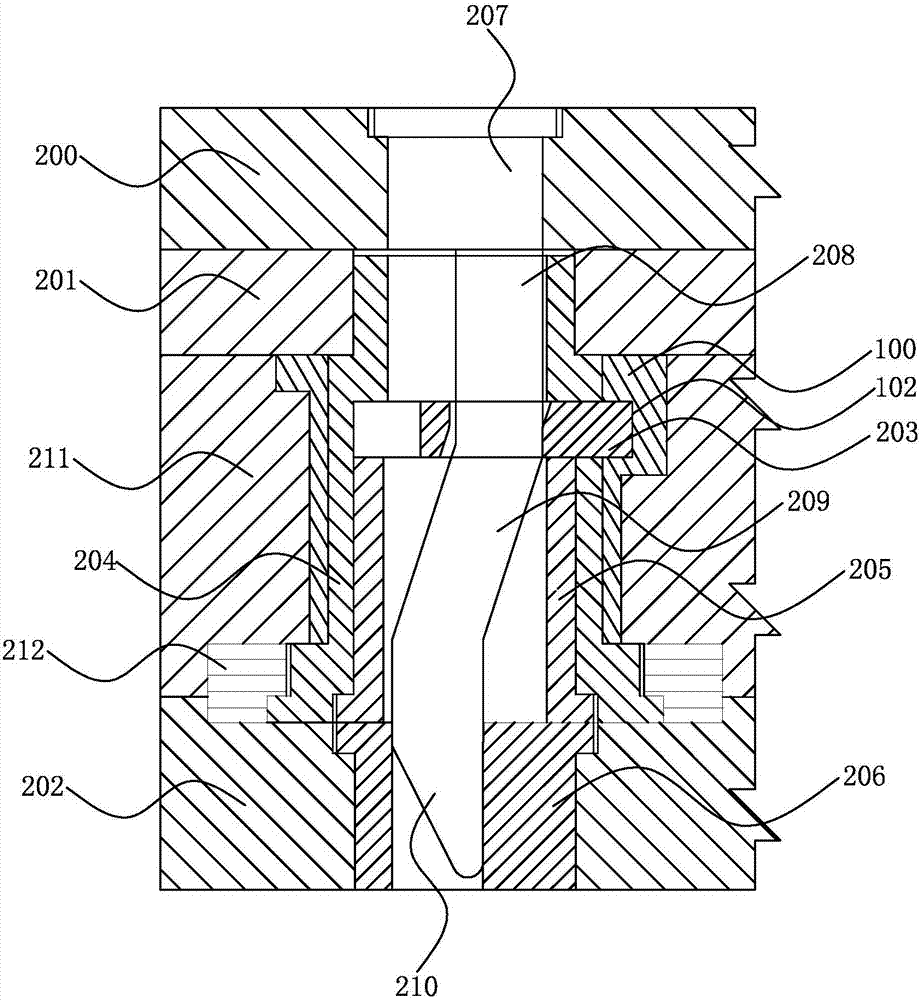

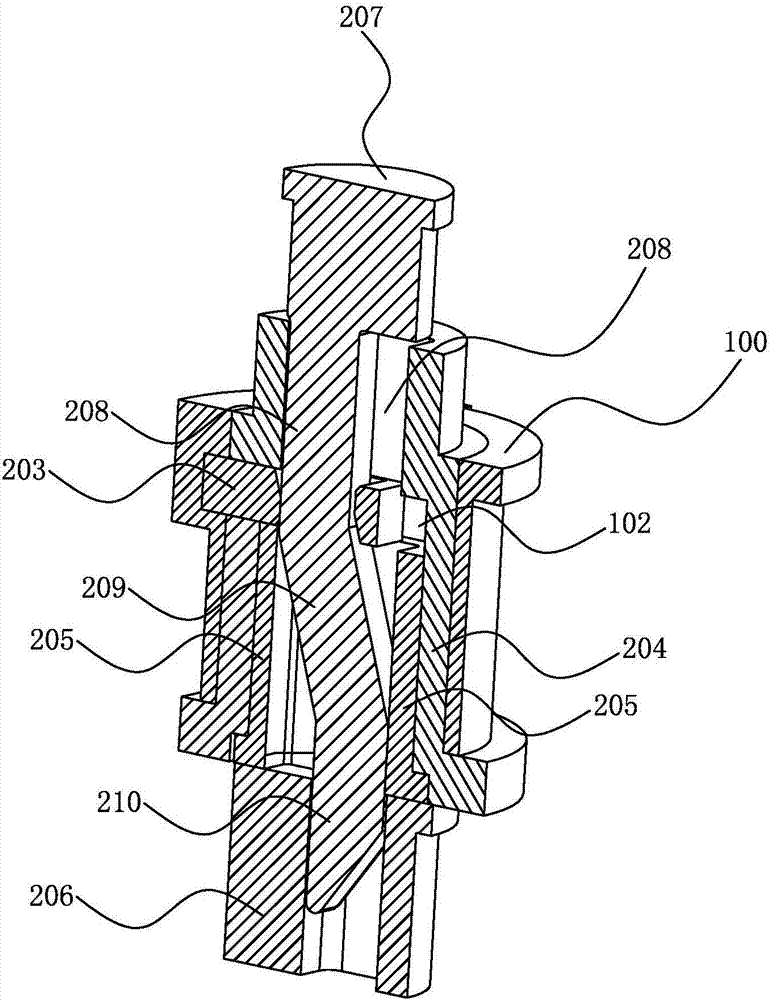

[0023] Please refer to figure 2 , image 3 ,in, figure 2 A schematic cross-sectional structure showing the clamping state of the pull-out push plate structure of the mold of the present invention, image 3 draw figure 2 Schematic diagram of the three-dimensional cross-sectional structure of the middle part of the structure.

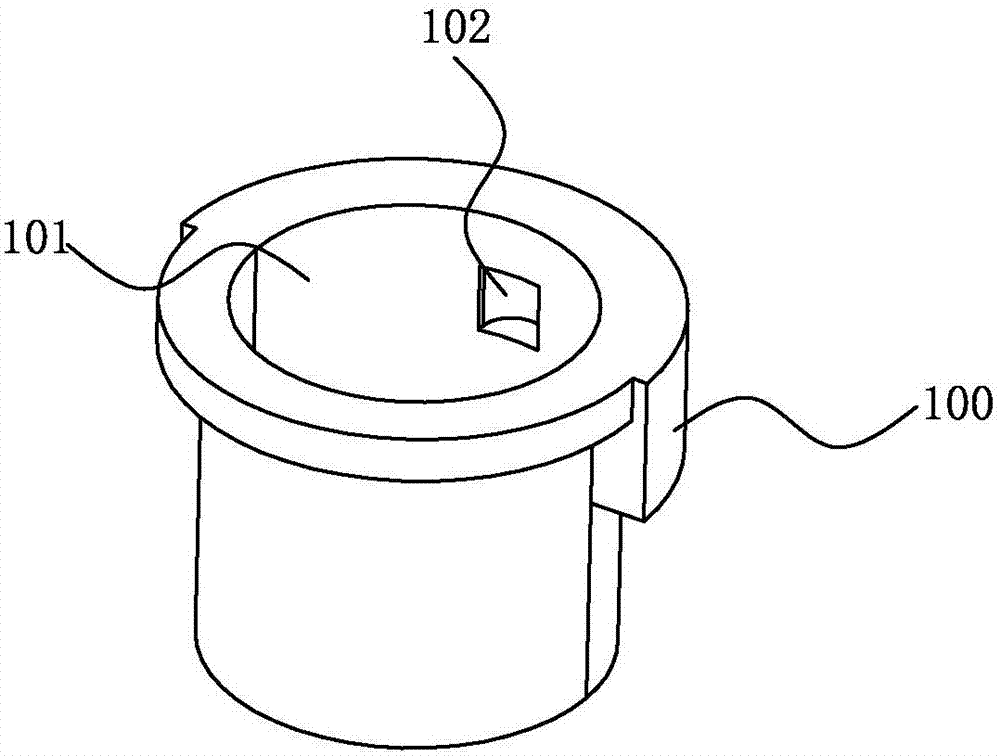

[0024] In order to achieve the above object, the mold of the present invention has an undercut exit structure on the side wall of the inner hole, which molds a product 100 with an undercut 102 on the side wall of the inner hole 101 (please refer to figure 1 ), the mold includes an upper fixed plate 200, a female template 201, a male template (not shown in the figure), and a male mold carrier plate 202 set up in sequence, and the mold also includes:

[0025] Sliding insert 203, one end of which has a forming portion for molding the undercut, and the sliding insert 203 has a sliding through hole;

[0026] The first inlet 204 forms the inner hole 101...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com