Symmetrical processing tool and processing method of herringbone gear hole keyway

A herringbone gear and tooling technology, which is used in metal processing equipment, planers, manufacturing tools, etc., can solve the problems of reducing the accuracy of the press, complicated operation, and difficult to guarantee the machining accuracy, and achieves improved symmetry accuracy and fast positioning. Accurate and improve the effect of processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

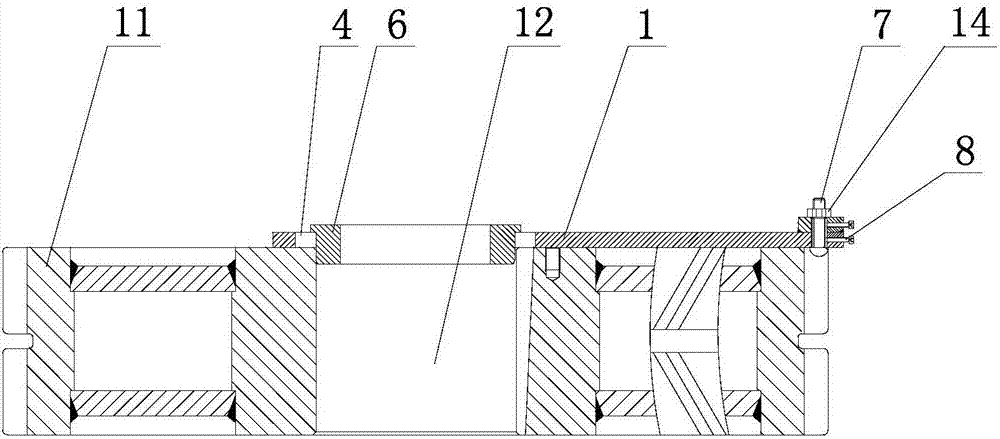

[0029] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

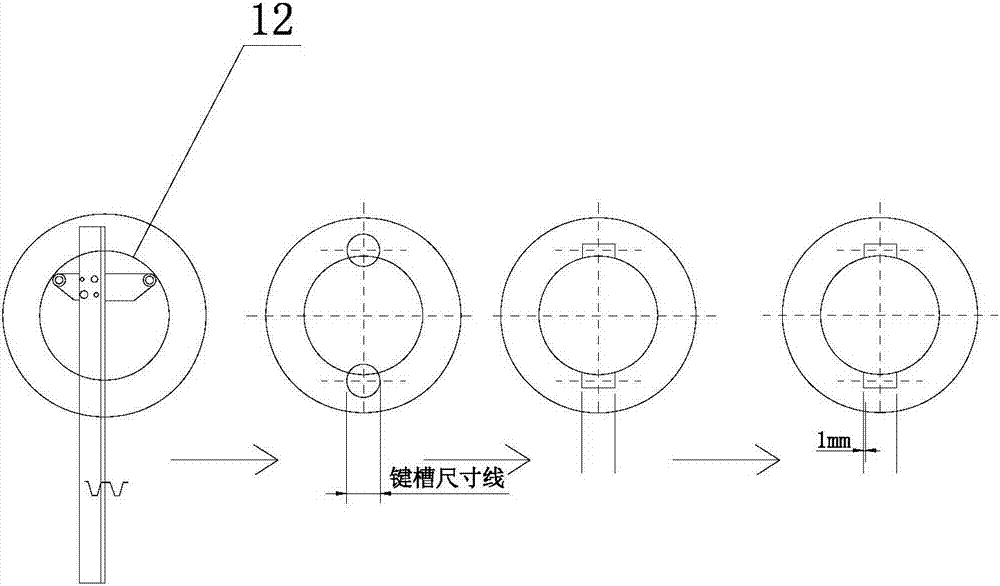

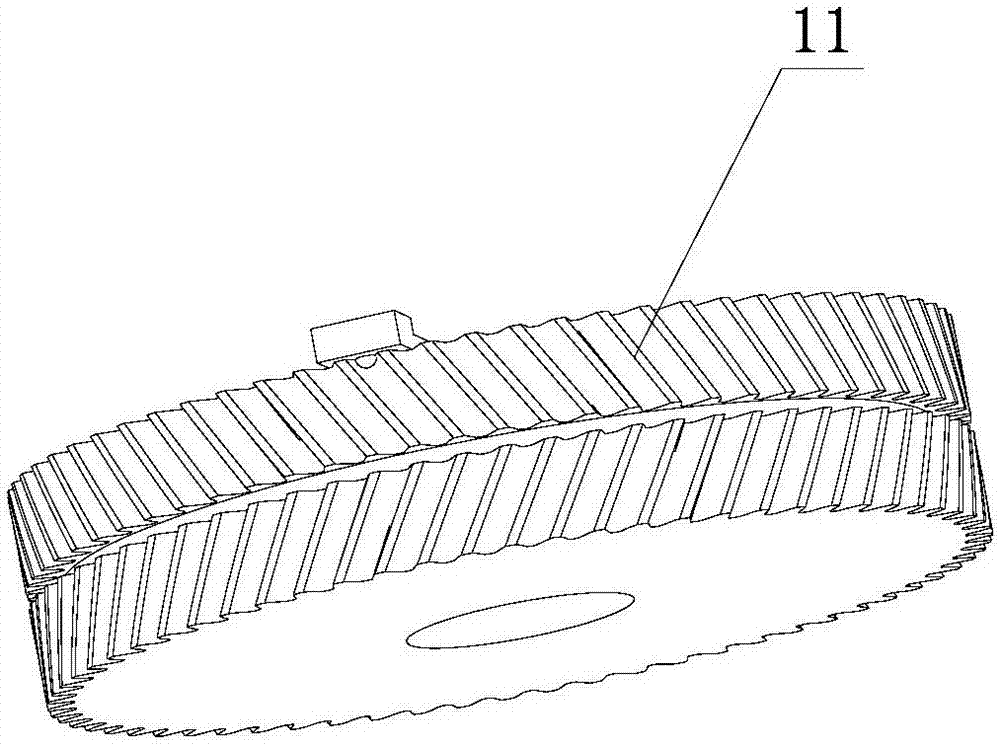

[0030] Such as Figure 3-8 As shown, the tooling for symmetrical processing of the keyway in the inner hole of the herringbone gear includes the tooling body 1, and the two ends of the tooling body 1 along the direction of the center line 16 are respectively provided with positioning holes 2 and tooth groove positioning holes 3, and the positioning holes 2 are about 2 along the direction of the center line 16. The tooling body 1 on both sides is respectively provided with a reference keyway 4, and the side wall at one end of the tooling body 1 is provided with a tooth groove positioning hole 3. There are several threaded holes 5 from top to bottom, and the centers of the threaded holes 5 are located on the center line of the side wall. , the positioning h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com