Gear top edge modifying method for improving gluing bearing capacity of involute cylindrical gear

An involute cylinder, bearing capacity technology, applied in the direction of elements with teeth, belts/chains/gears, portable lifting devices, etc., can solve problems such as unsatisfactory results, achieve practical methods, pitting and gray spots The effect of reducing the phenomenon and improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

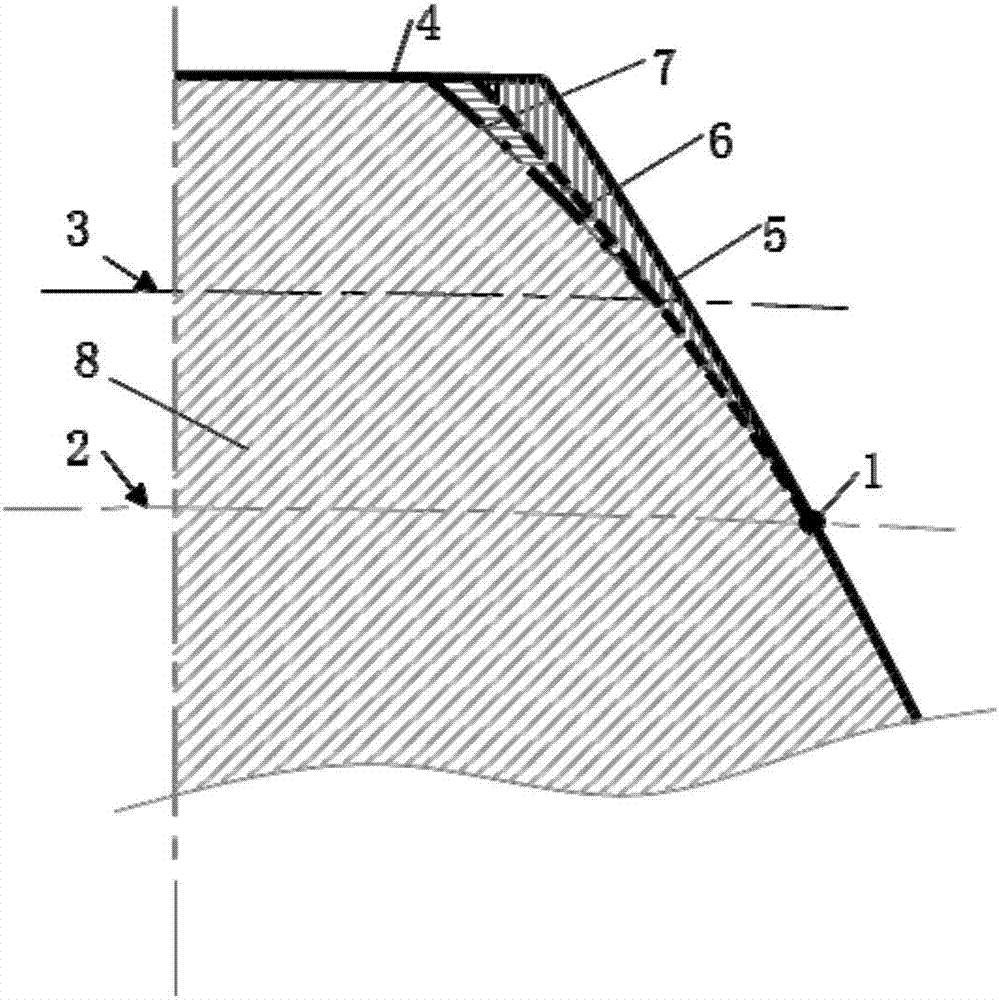

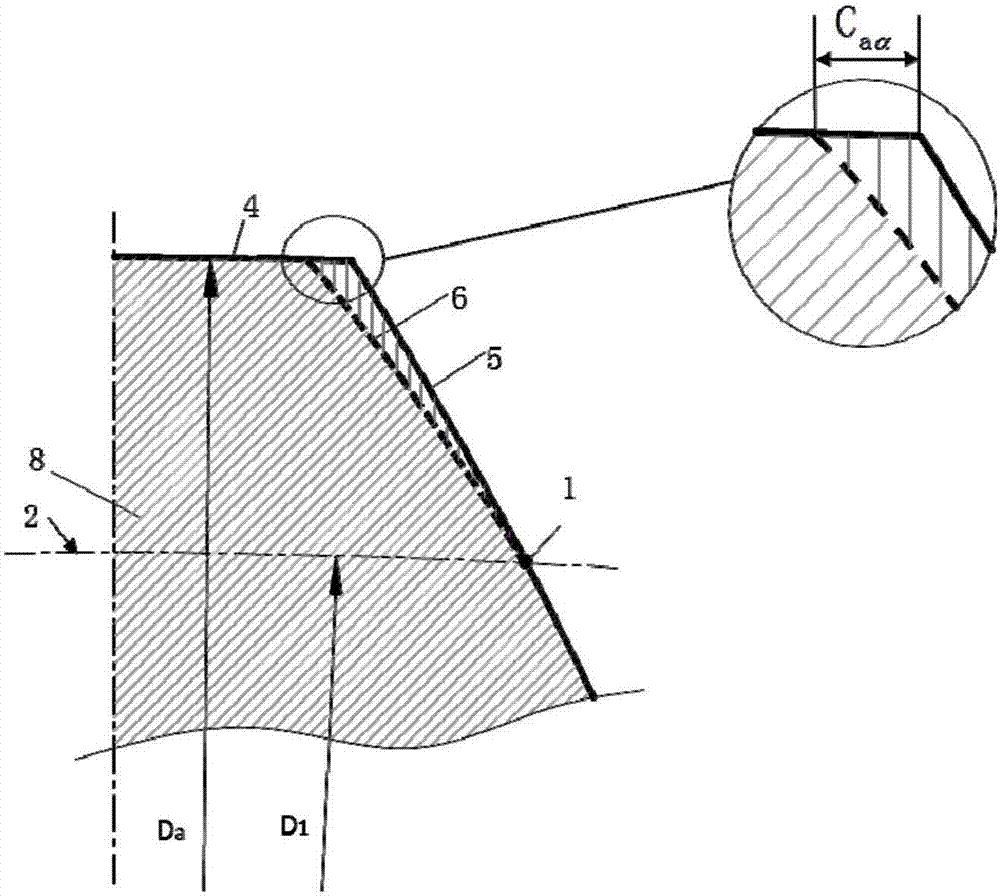

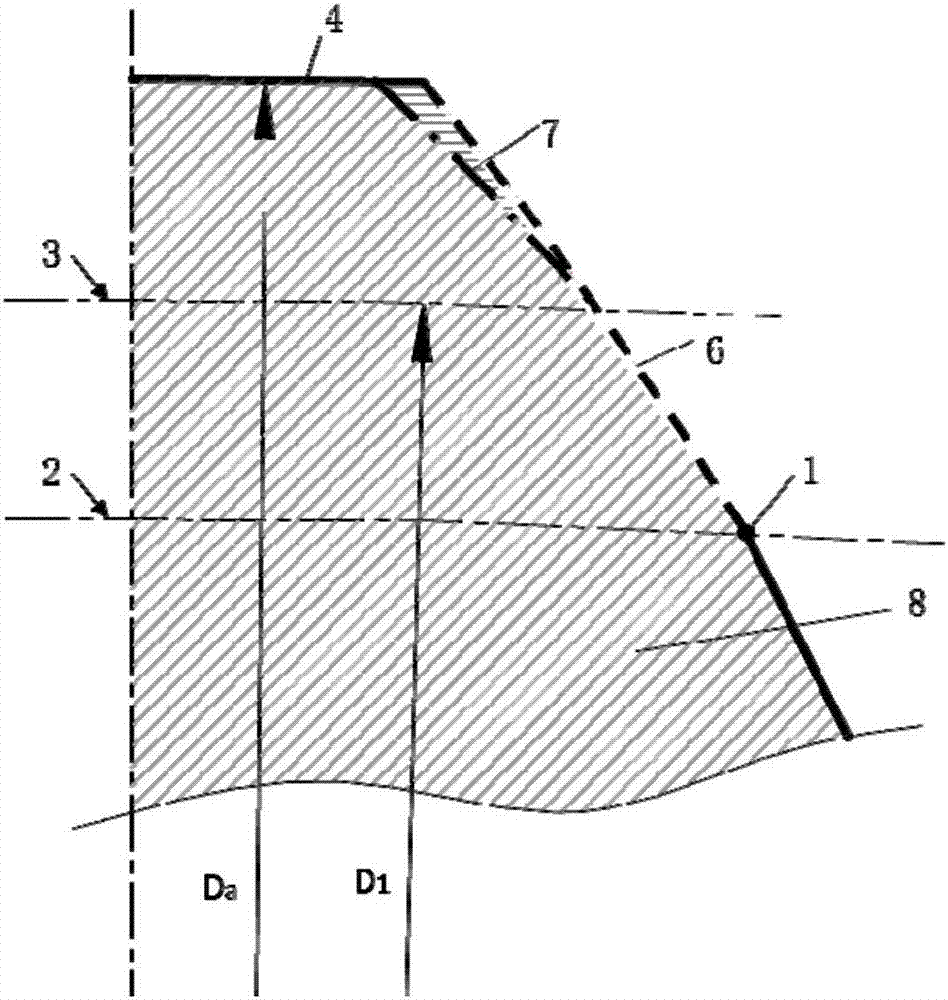

[0024] Such as figure 1 As shown, in the present invention, a tooth tip trimming method for improving the gluing bearing capacity of involute cylindrical gears, the tooth tip trimming curve is composed of two segment trimming curves: the first segment trimming curve is composed of the first The segment fitting curve 6 is fitted, and the second segment of the edge repairing curve is fitted by the second segment of the fitting curve 7 .

[0025] Such as figure 2 As shown, first determine the first fitting curve 6: the first fitting curve 6 is a curve from the highest point 1 on the involute line of the tooth surface to the addendum circle 4 when the least teeth participate in meshing. The first fitting curve 6 is locat...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap