Method for determining yielding surface by crossed pre-stretching deformation and loading

A cross-stretching and tensile yield strength technology, applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problem of not being able to reflect the stress state well, not well characterizing the anisotropy of metal materials, Unable to meet the molding process and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

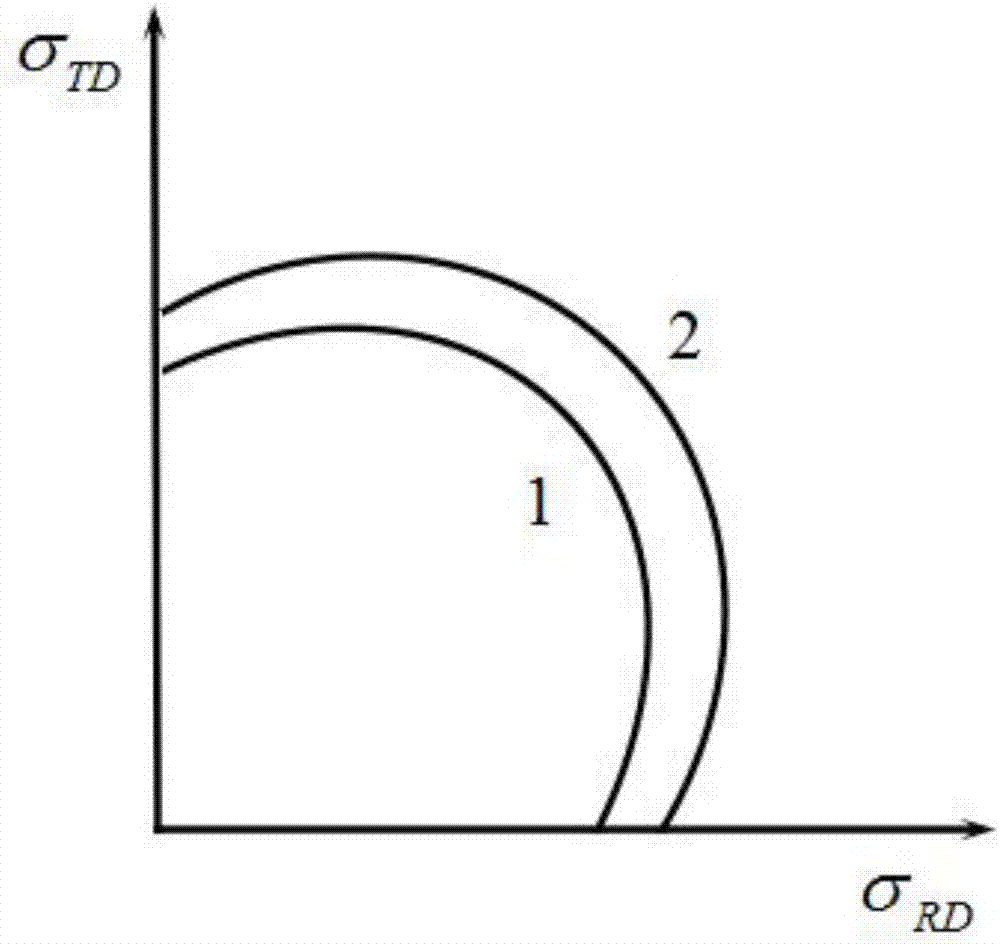

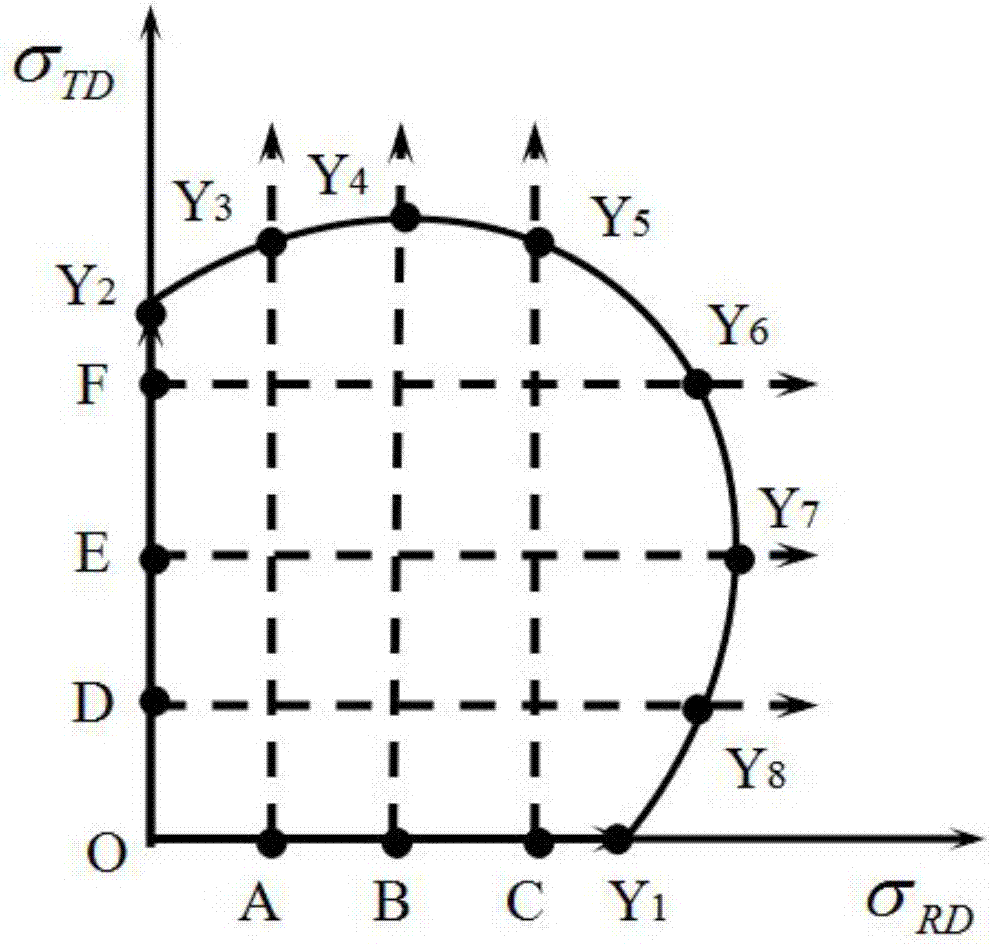

[0026] Measure the metal material yield surface with a kind of method of cross tension pre-deformation loading of the present invention to measure the yield surface, such as figure 2 As shown, it mainly includes the determination of initial yield surface 1 and subsequent yield surface 2. Let σ RD , σ TD Be respectively sheet metal rolling direction (hereinafter referred to as RD direction) and transverse direction (hereinafter referred to as TD direction) tensile yield strength, and the method steps are as follows:

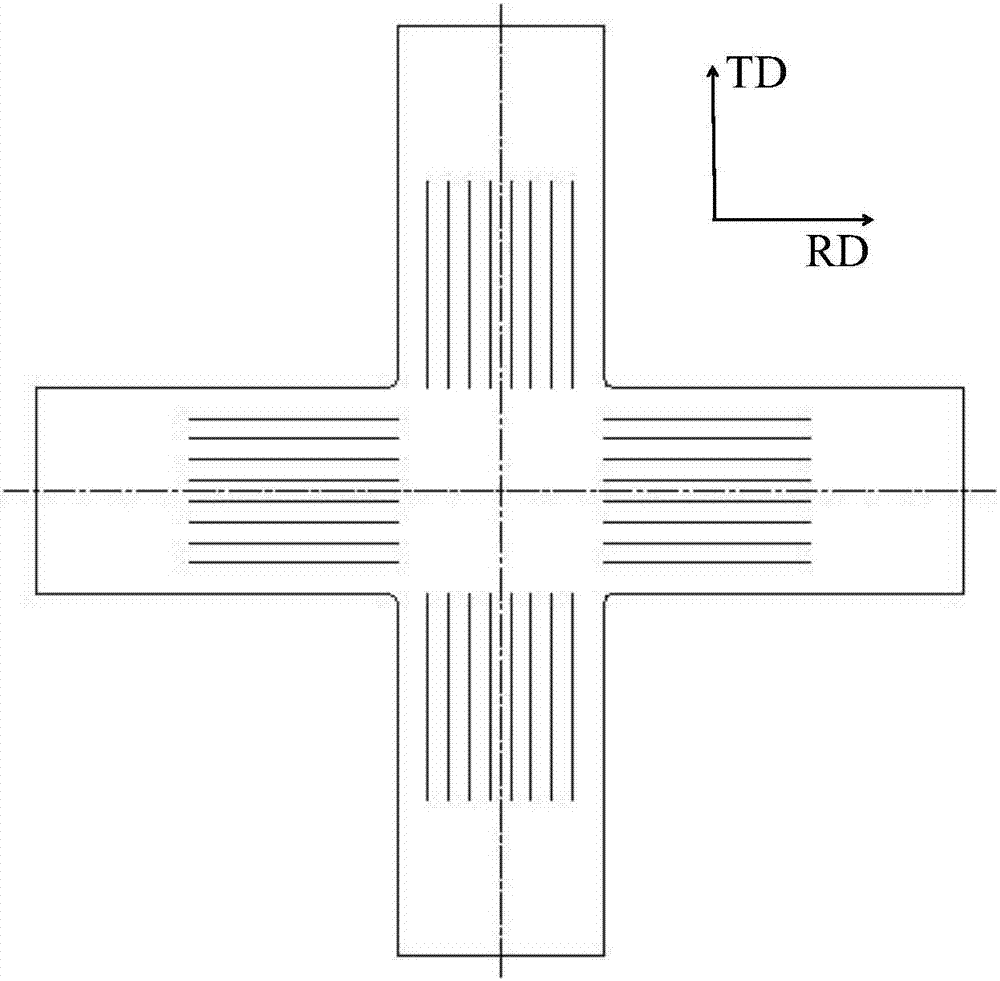

[0027] Step 1: Prepare two RD direction uniaxial tensile specimens along the RD direction of the plate, prepare one TD direction uniaxial tensile specimen along the plate TD direction; prepare 11 such as figure 1 The cross tensile specimen shown;

[0028] Step 2: Take a uniaxial tensile sample prepared in the RD direction and a uniaxial tens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com