Method for measuring yield surface of metal material

A measurement method and technology of metal materials, applied in the direction of analyzing materials, using stable tension/pressure to test the strength of materials, measuring devices, etc., can solve the problems that are not suitable for metal materials and can not reflect the plastic deformation anisotropy of materials well Behavior, unable to characterize the anisotropy of metal materials well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

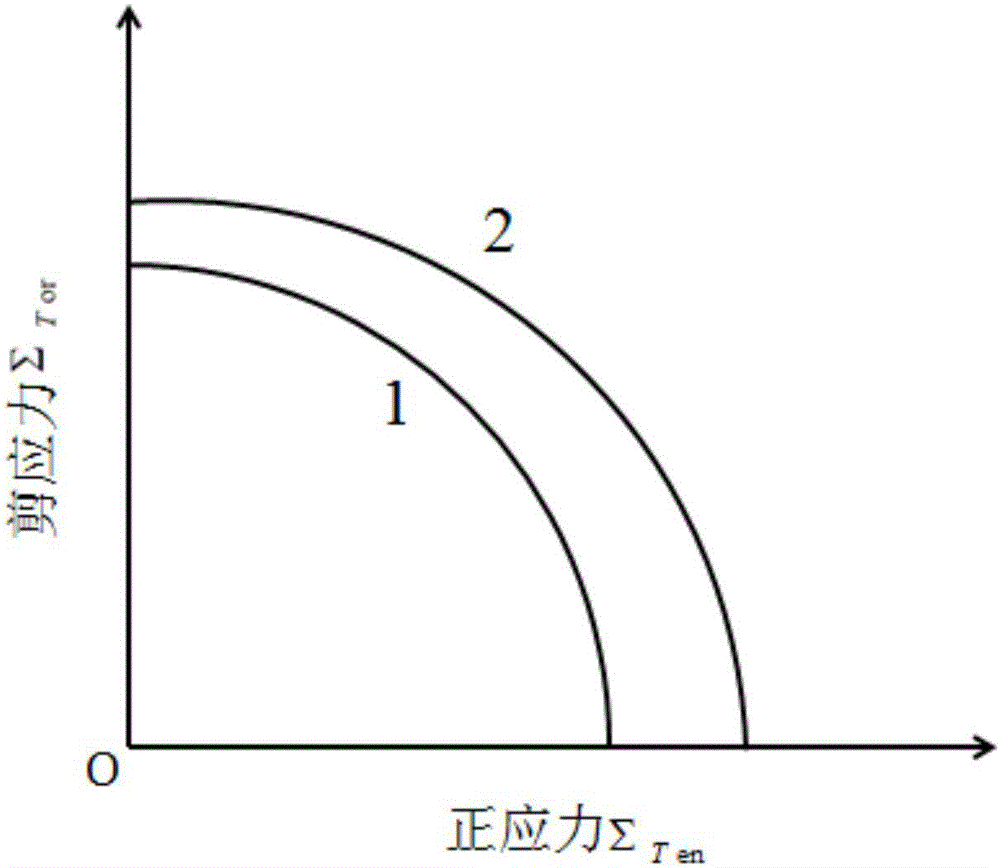

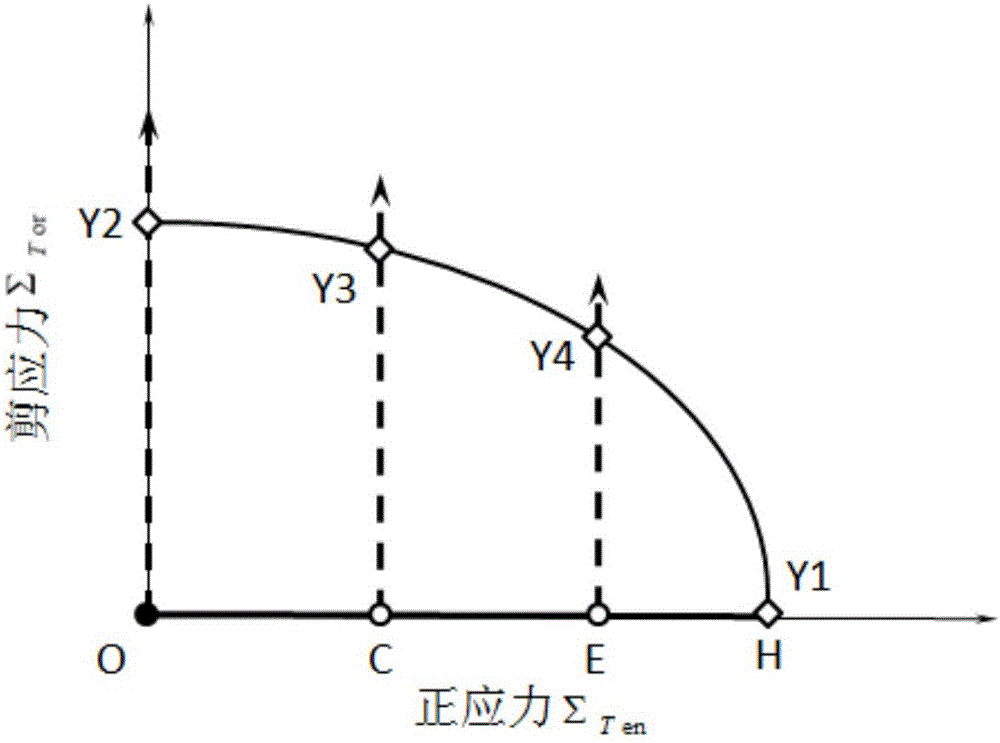

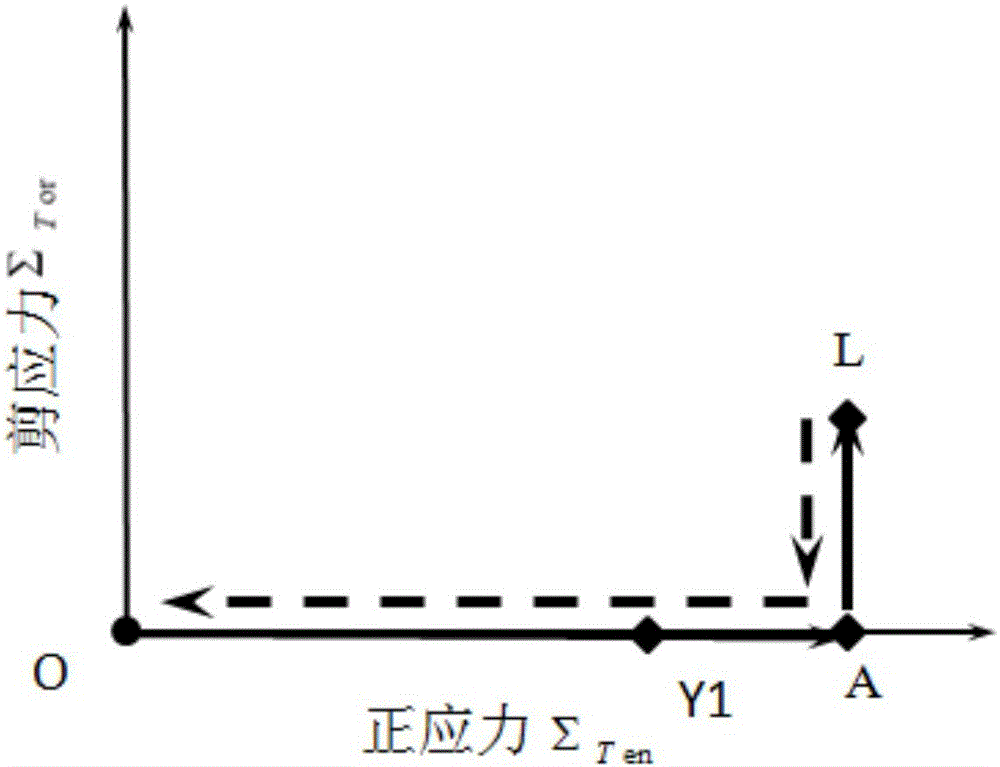

[0020] A method for measuring the yield surface of a metal material in the embodiment of the present invention mainly includes the measurement of the initial yield surface 1 and the subsequent yield surface 2, such as figure 1 shown. Let σ Ten , σ Tor are the tensile yield strength and torsional yield strength respectively, the specific steps are as follows:

[0021] Step 1: Prepare 9 tensile-torsion combined test specimens according to the material mechanics test standard, respectively marked as 1#, 2#, 3#, 4#, 5#, 6#, 7#, 8#, 9#.

[0022] Step 2: Take 1# sample and 2# sample, and then perform unidirectional tensile and torsional loading respectively, measure the tensile and torsional stress-strain curve, and determine the tensile and torsional stress-strain curves according to the tensile and torsional stress-strain curves. torsional yield strength an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com