Single-reaction cup luminescence measurement method

A luminescence measurement and reaction cup technology, applied in the field of medical equipment, can solve problems affecting the service life and accuracy of photon counters, and achieve the effects of preventing missing photons, improving collection accuracy, and ensuring service life and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

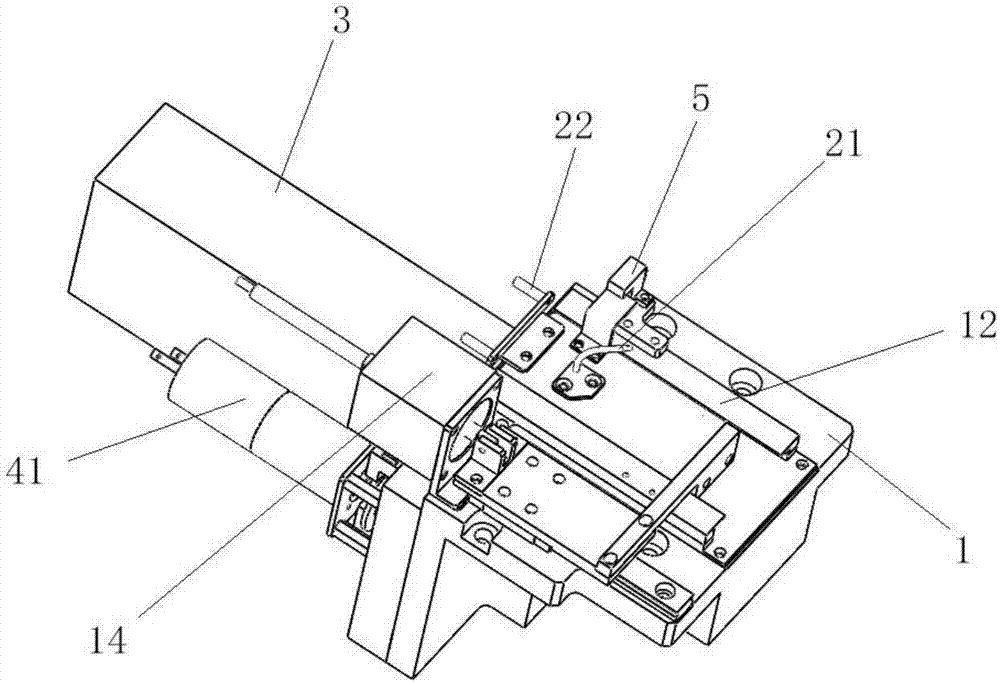

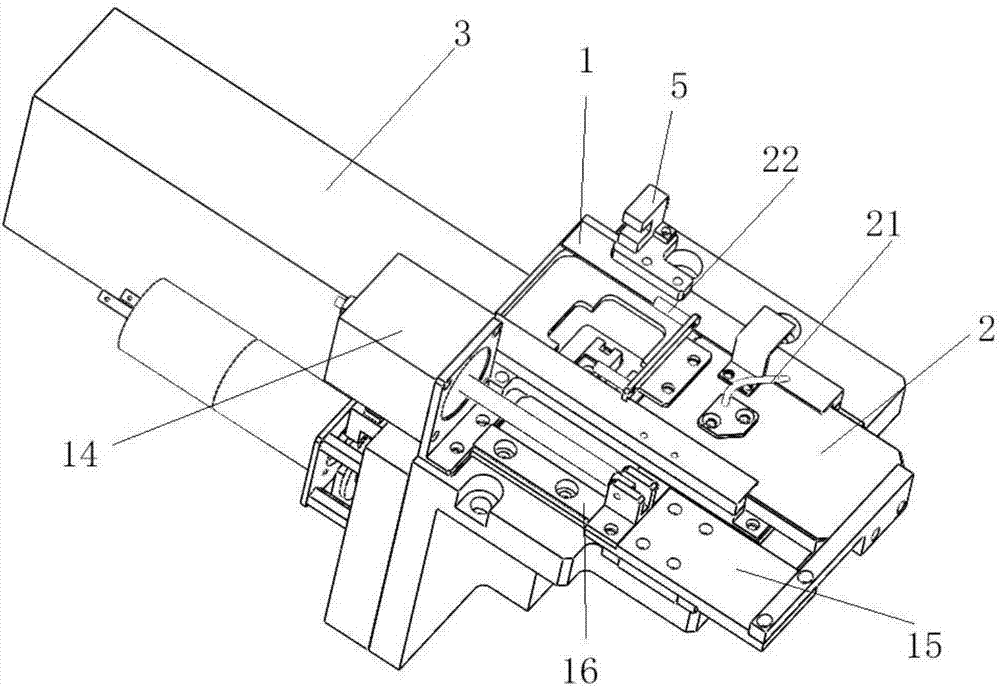

[0033] This embodiment provides a single cuvette luminescence measurement device, such as figure 1 or 2: Include:

[0034] The measurement chamber 1 is open at the top, and has an accommodating cavity for cuvettes inside, and a guide rail 12 on the top, a photon hole on the side, and a switch cover driver 14 installed;

[0035] The top cover 2 is slidably arranged on the guide rail 12 at the top of the measurement chamber 1, and can move along the guide rail 12 under the drive of the switch cover driver 14, so as to be between the position of closing the opening of the measurement chamber 1 and the position of opening the opening of the measurement chamber 1 The top cover 2 is also provided with a reagent adding tube 21. When the top cover 2 is in the position of closing the opening of the measurement chamber 1, the liquid can flow into the cuvette located in the accommodating chamber by injecting the liquid into the reagent adding tube 21, which is convenient for various reac...

Embodiment 2

[0042] This embodiment provides a single cuvette luminescence measurement method, which is carried out in the single cuvette luminescence measurement chamber of Example 1;

[0043] Perform the following steps in order:

[0044] S1: Start the switch cover driver 14 to make the top cover 2 open the opening of the measurement chamber 1, and send the cuvette into the accommodating chamber of the measurement chamber 1;

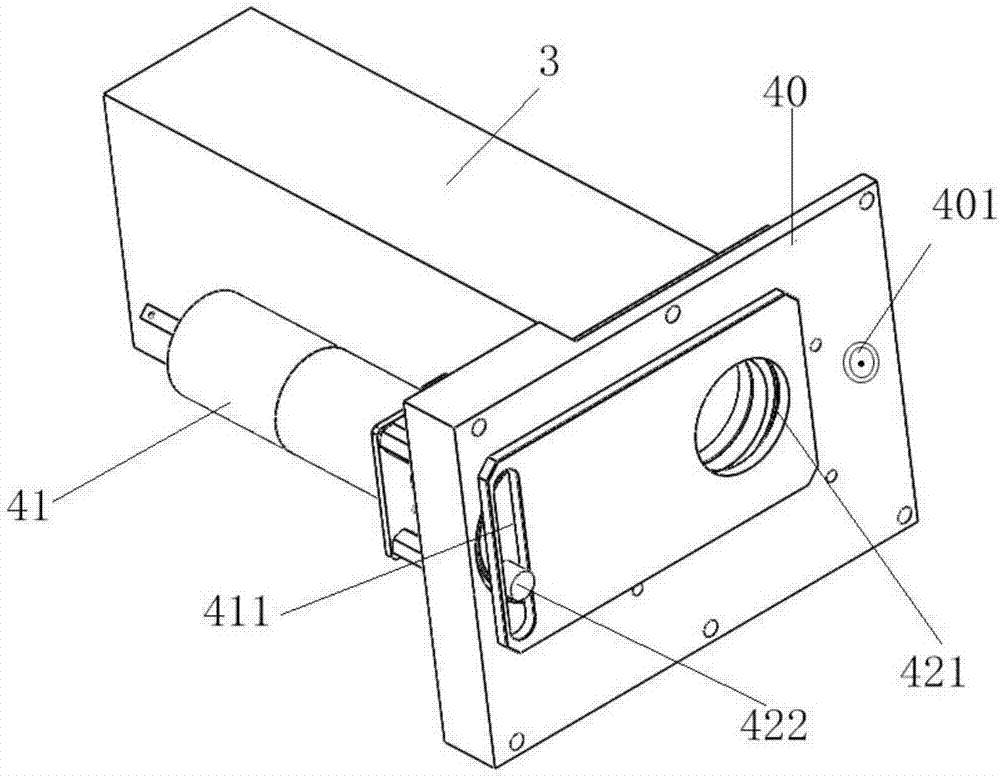

[0045]S2: Start the switch cover driving part 14 to make the top cover 2 close the opening of the measurement chamber 1, and start the rotating driving part 41 to make the through hole 421 on the baffle 42 coincide with the photon passing hole, and start the photon counter 3;

[0046] S3: adding the starter and the triggering agent into the cuvette through the reagent adding tube 21;

[0047] S4: After a period of time, start the rotary drive member 41 to misalign the through hole 421 on the baffle plate 42 with the photon via hole;

[0048] S5: Start the switch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com