Automatic feeding device for square strips

An automatic loading and feeding device technology, applied in the direction of transportation and packaging, conveyors, conveyor objects, etc., can solve problems such as low labor efficiency, limiting planer automation production efficiency, and high labor intensity of employees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

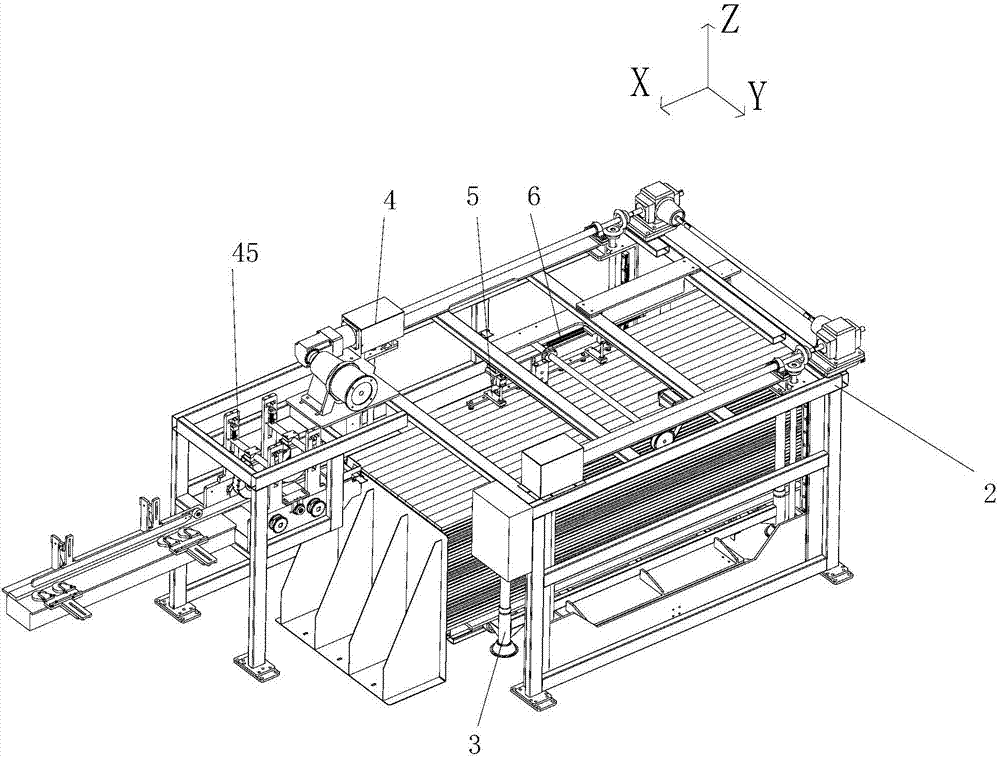

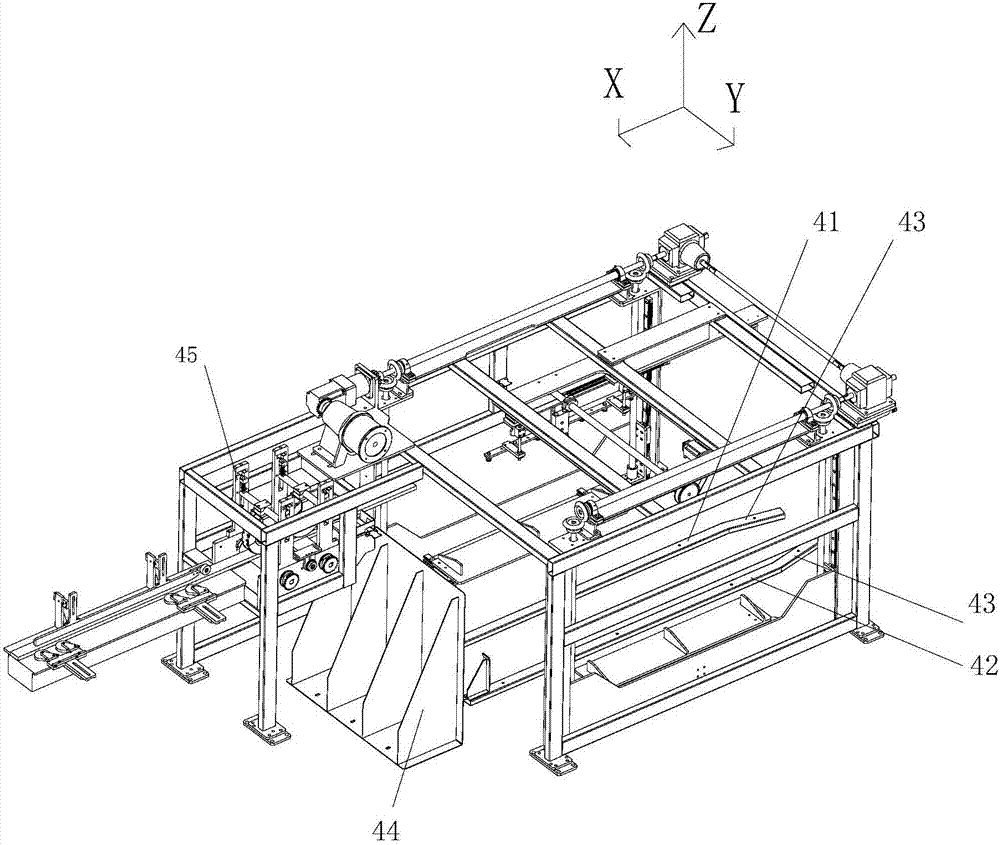

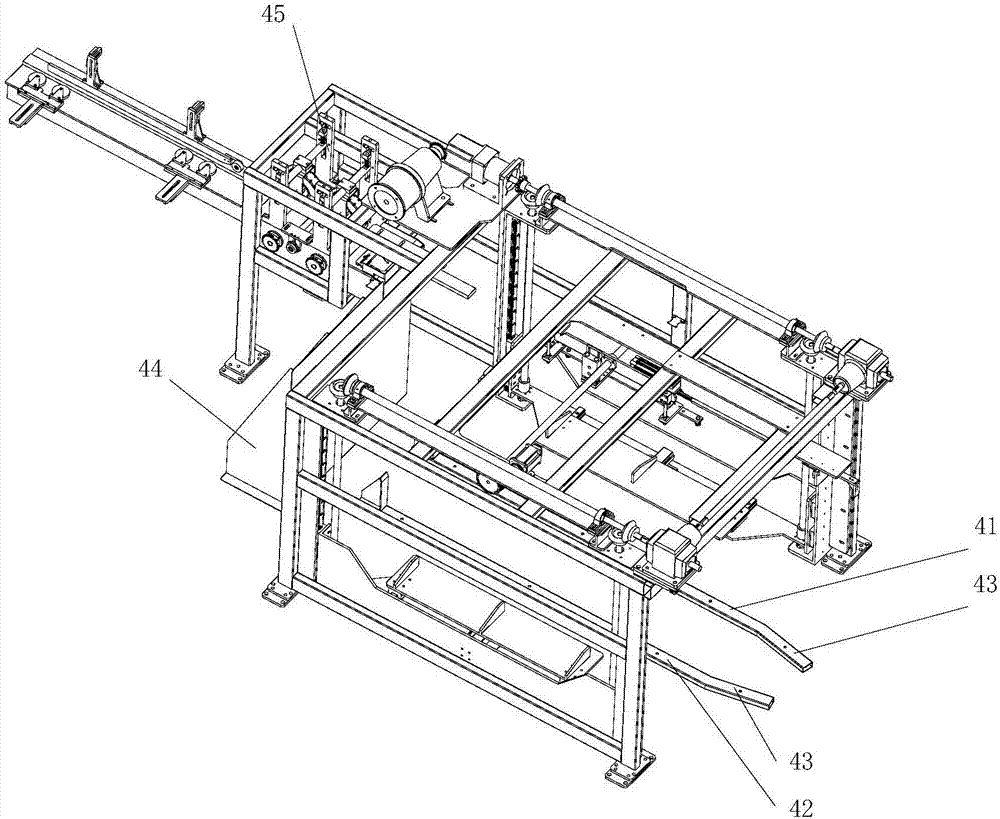

[0038] Such as Figure 1-9 As shown, a square strip automatic feeding device includes: frame 2, material cart 3, lifting device 4, translation device 5, feeding device 6;

[0039] The lifting device 4, the translation device 5, and the feeding device 6 are arranged on the frame 2;

[0040]Described material trolley 3 comprises square strip carrying plate 7, retaining column 8, caster 9, square bar 1 is stacked on square bar carrying plate 7, and there are four retaining columns 8, and four retaining columns 8 are respectively arranged on square bar carrying plate 7 The four corners of the four corners, the retaining column 8 is used to limit the movement of the square bar 1 along the Y axis, and the bottom of the square bar bearing plate 7 is also provided with four casters 9, which are convenient for the material vehicle 3 to move;

[0041] The lifting device 4 has two sets, and the two sets of lifting devices 4 are arranged oppositely. The lifting device 4 is composed of a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com