Defect detecting method of propping bolts at ends of diagonal bracing

A technology for bolt tightening and defect detection, which is applied in the direction of optical testing of defects/defects, measuring devices, and material analysis through optical means, which can solve problems such as low efficiency, high risk of human observation, complex environment, etc., to achieve exclusion safety hidden effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will be described below with reference to the drawings. The same components are assigned the same reference numerals in the various figures.

[0024] The catenary is one of the main power supply devices in the electrified railway, which is erected along the railway line. It is a special form of transmission line that transmits electric energy to electric locomotives through direct contact with the electric locomotive pantograph.

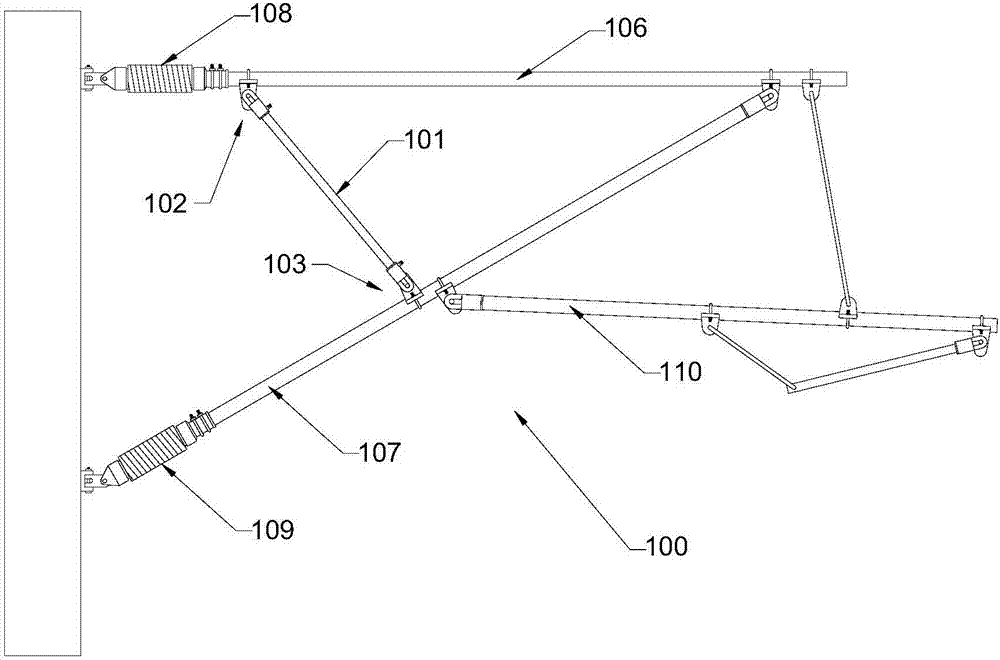

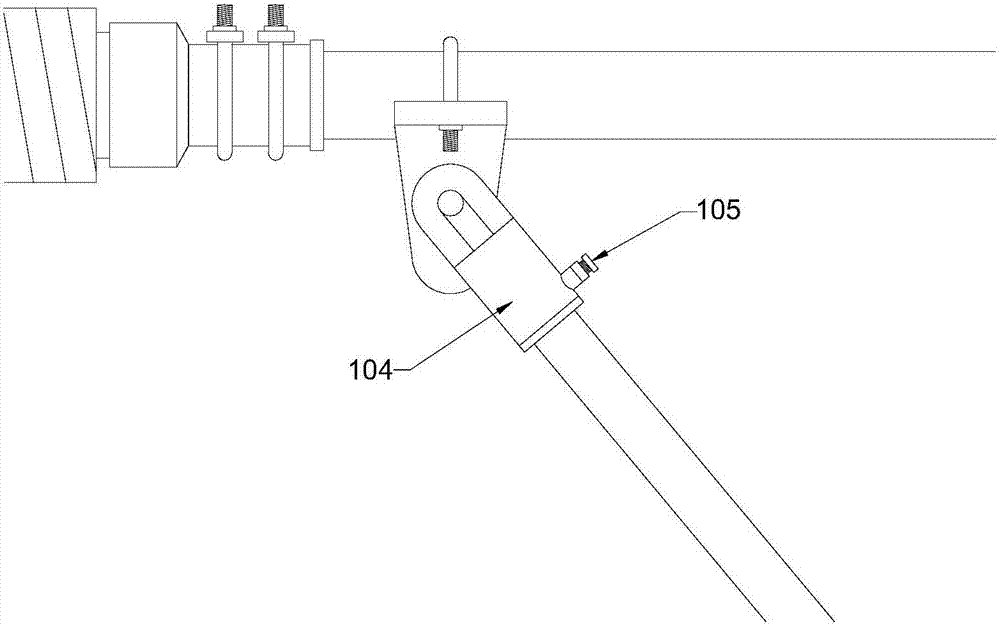

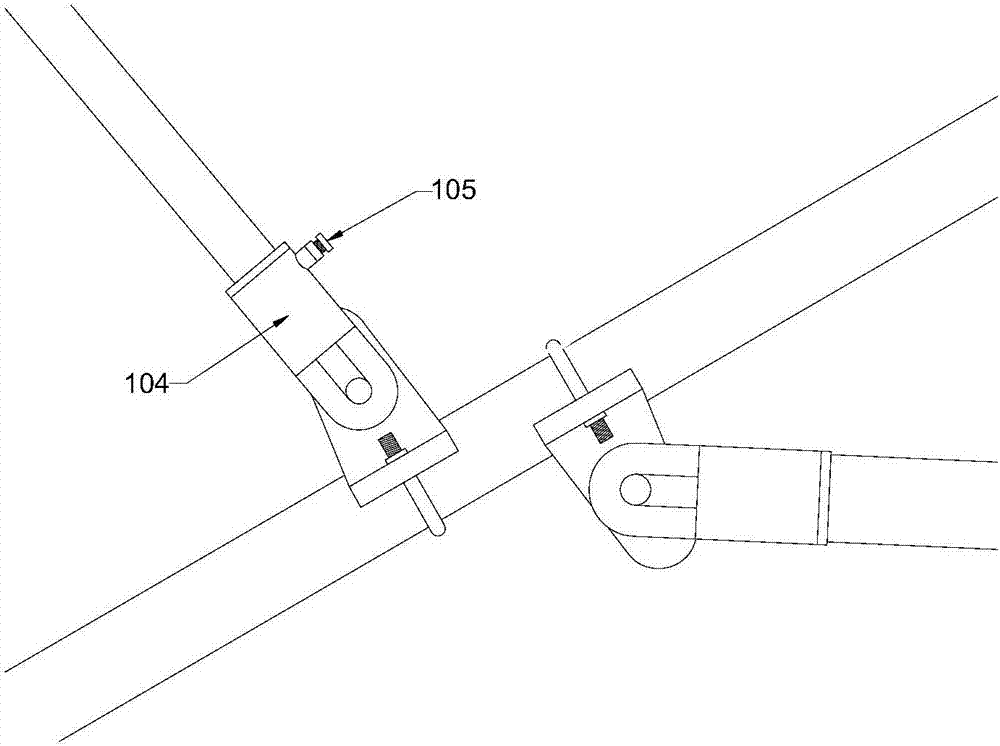

[0025] The support device is one of the components of the catenary. figure 1 is a schematic diagram of the supporting device. The following mainly describes the structure related to the diagonal brace. Such as figure 1 As shown, the support device 100 has a transverse arm 106 and an oblique arm 107 , the transverse arm has a transverse arm insulator 108 , and the oblique arm has an oblique arm insulator 109 . The diagonal brace 101 is connected between the transverse wrist arm and the diagonal wrist ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com