A stator clapping machine

A press and stator technology, which is applied in the manufacture of stator/rotor bodies, etc., can solve problems such as affecting the efficiency of stator beat pressure, and achieve the effect of improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

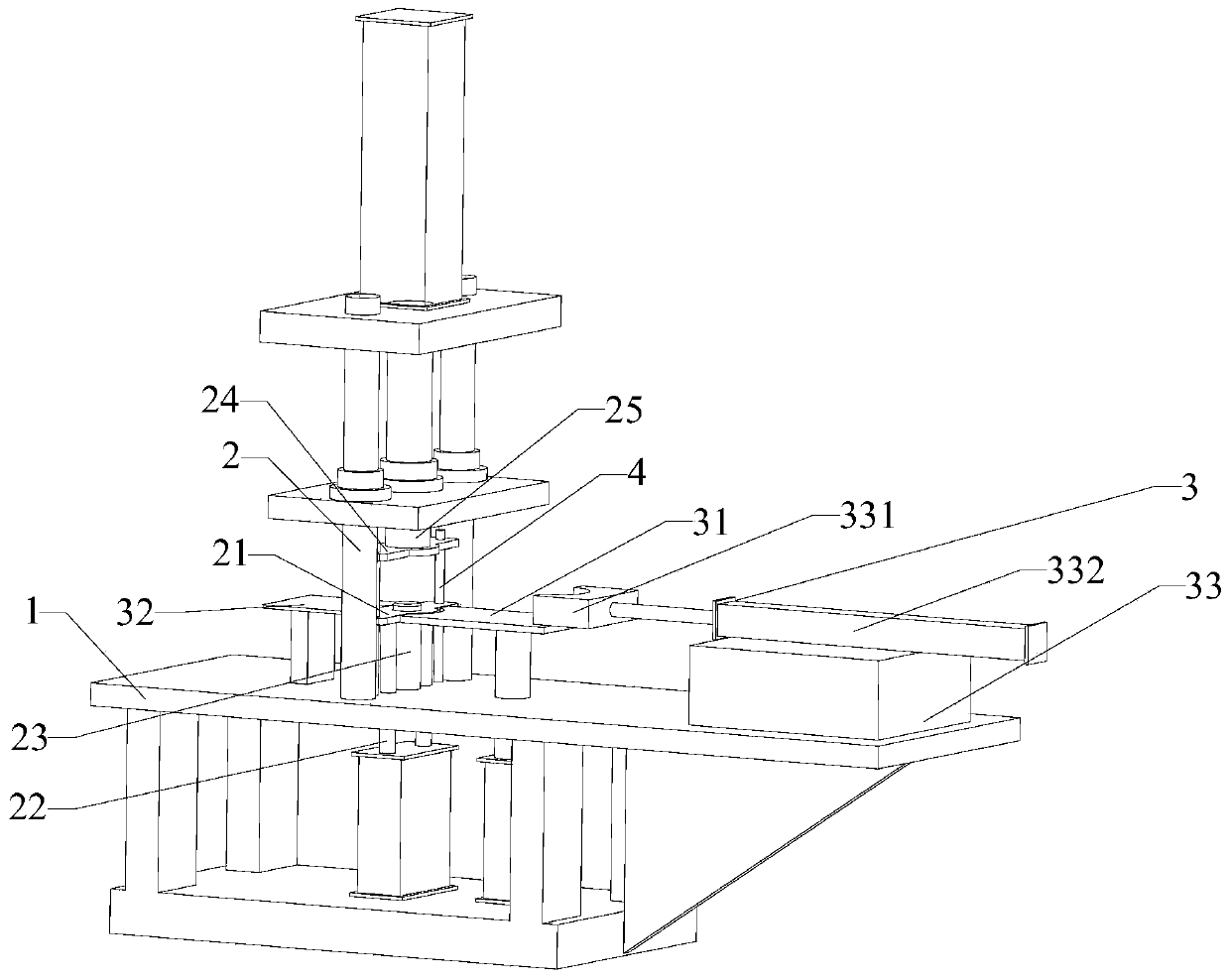

[0064] A stator slapping machine, comprising a base 1, a slapping mechanism 2, a delivery mechanism 3 and a servo driver; the slapping mechanism 2 and the delivery mechanism 3 are connected to the base 1; the slapping mechanism 2 includes a base 21 , the base 21 lifting cylinder, the limit block 23 and the hydraulic clapping mechanism 2; the limit block 23 is a cylinder with the same diameter as the inner diameter of the stator core; the axial direction of the limit block 23 is vertical direction; the edge of the upper surface of the limit block 23 is provided with chamfers; Move in a straight direction; the hydraulic clapping mechanism 2 includes a pressure block 24 and an oil pressure rod 25 connected to the top of the pressure block 24, the pressure block 24 is a ring cylinder whose inner diameter is the same as that of the limit block 23, The briquetting block 24 moves vertically under the action of the oil pressure rod 25; the conveying mechanism 3 includes a feeding plat...

Embodiment 2

[0066] A stator slapping machine, the distance between the feeding platform and the base 21 is 5 mm; the distance between the discharging platform 32 and the base 21 is 5 mm; other features are the same as those in Embodiment 1.

Embodiment 3

[0068] A stator slapping machine, the distance between the feeding platform and the base 21 is 10 mm; the distance between the discharging platform 32 and the base 21 is 10 mm; other features are the same as those in Embodiment 1.

[0069] To sum up, the base of the stator cladding machine provided by the present invention is designed as a liftable base. When the stator core to be clapped needs to be placed on the base or the stator core needs to be removed after stamping, the base is lifted on the base. Driven by the cylinder, it moves to the same plane as the upper surface of the limit block, the feeding platform and the discharging platform, so that the feeding or unloading of the stator core can be automatically completed through the pusher, and the stator core is directly connected to the stator core without manual work. The limit block of the base avoids the risk of the operator's hands being crushed. While the stator slapping machine is slapping, the operator can place t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com