Coating device of subuliform spiral spring

A coil spring and coating device technology, applied in the field of springs, can solve the problems of decreased effect and uneven coating, and achieve the effect of compact structure, efficient and accurate coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

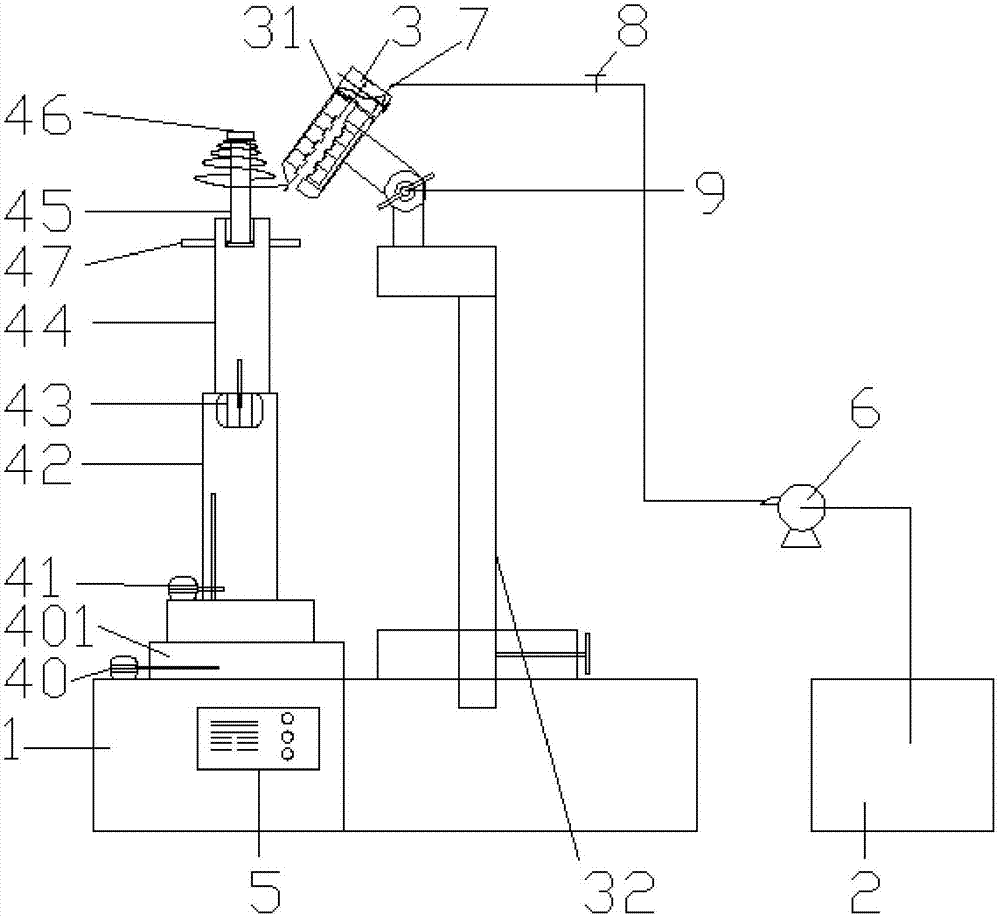

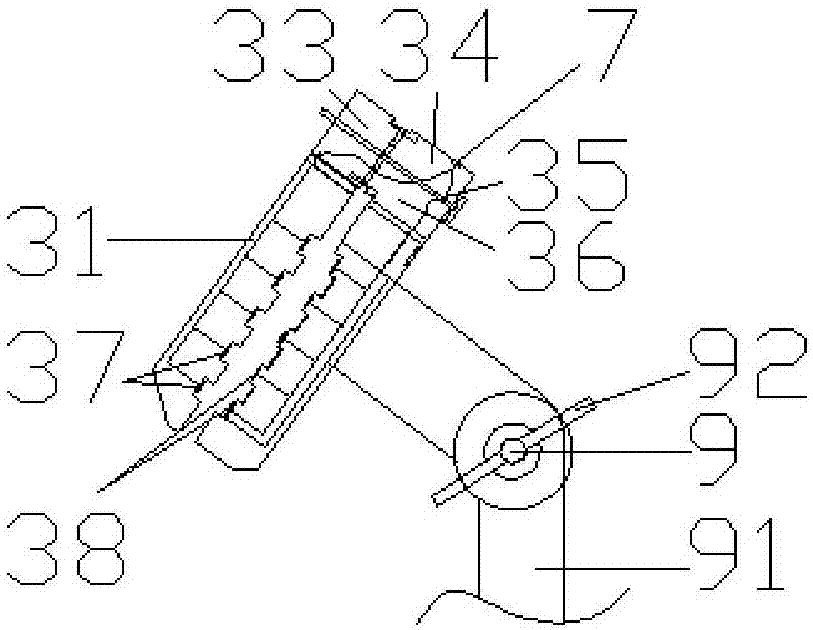

[0018] In order to more clearly illustrate the technical solutions in the embodiments of the present application or the prior art, the following will briefly introduce the drawings that need to be used in the description of the embodiments or the prior art, and the drawings in the following description are only the application For some embodiments described in , those skilled in the art can also obtain other drawings based on these drawings without creative work.

[0019] Combine below Figure 1~2 And specific embodiment, further clarifies the present invention.

[0020] Such as Figure 1~2 , a conical coil spring coating device, comprising a main frame 1, a coating pool 2, a liquid spray device 3, a feeding device 4, and a controller 5, the liquid spray device 3 is installed on one side of the main frame 1, and the feeding device is installed on the other side Device 4, the liquid spray device 3 includes a spray gun 31 and a fixed height adjustment rod 32 at the bottom of t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap