Dish washing machine distributor small cavity automatic liquid replenishing device

A technology of automatic liquid replenishment device and dispenser, which is applied in the direction of tableware washing machine/rinsing and washing machine parts, etc., which can solve the problems of inconvenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific embodiments.

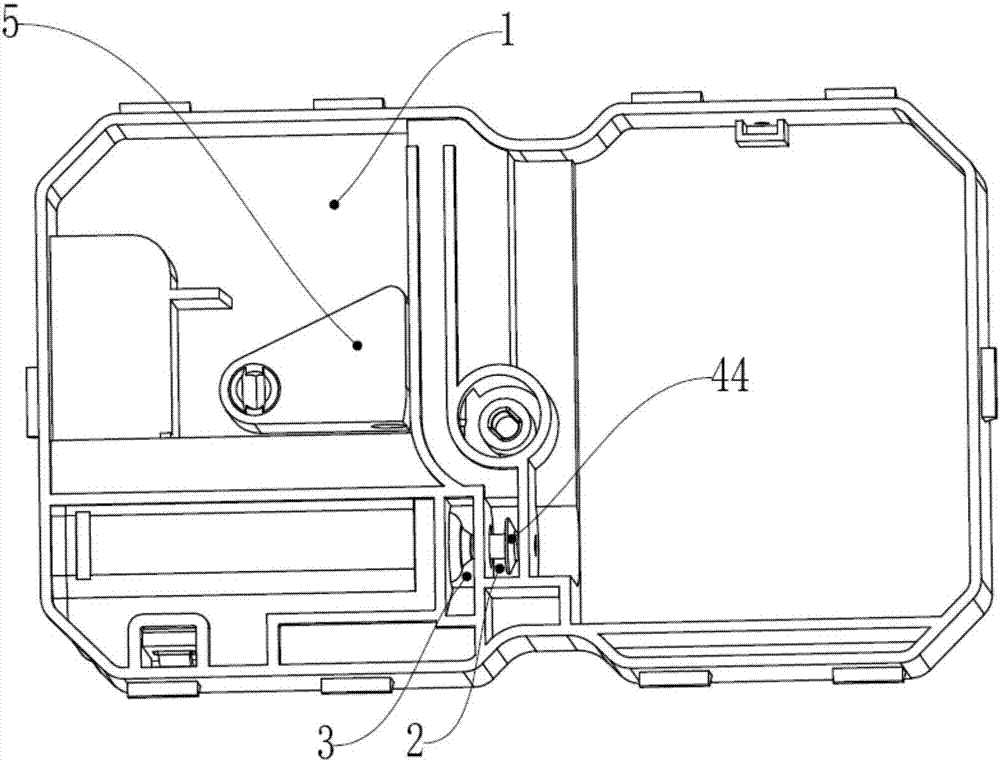

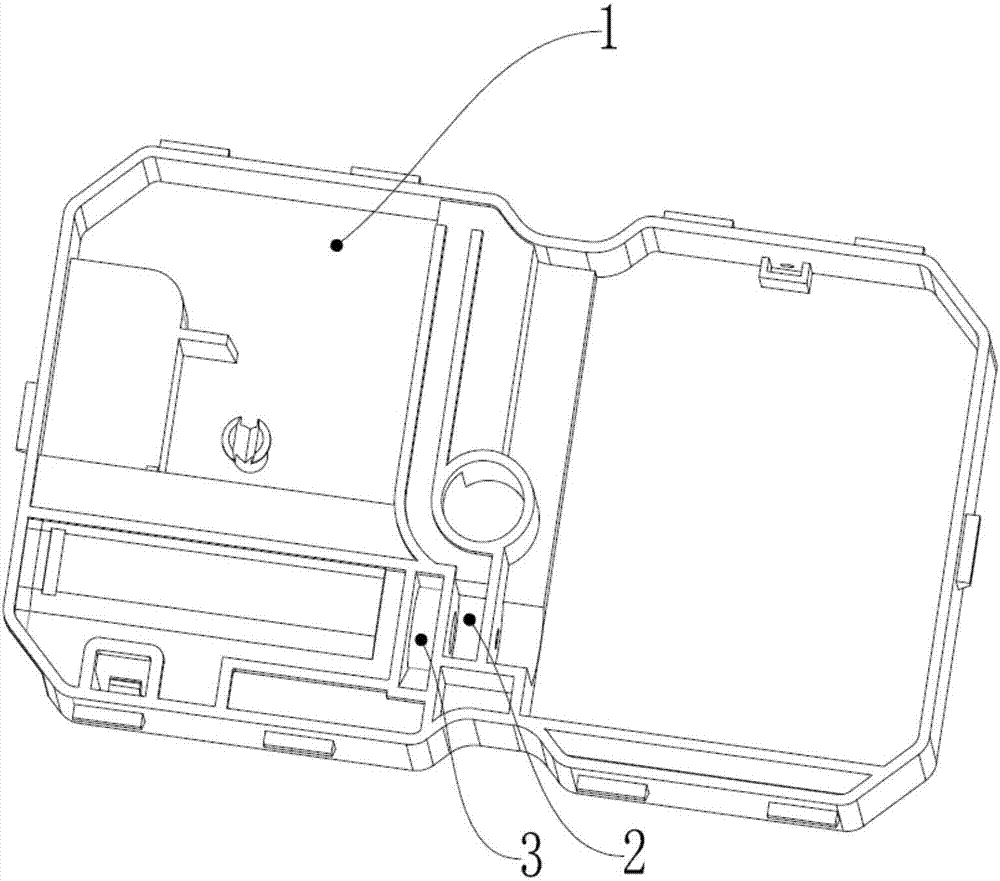

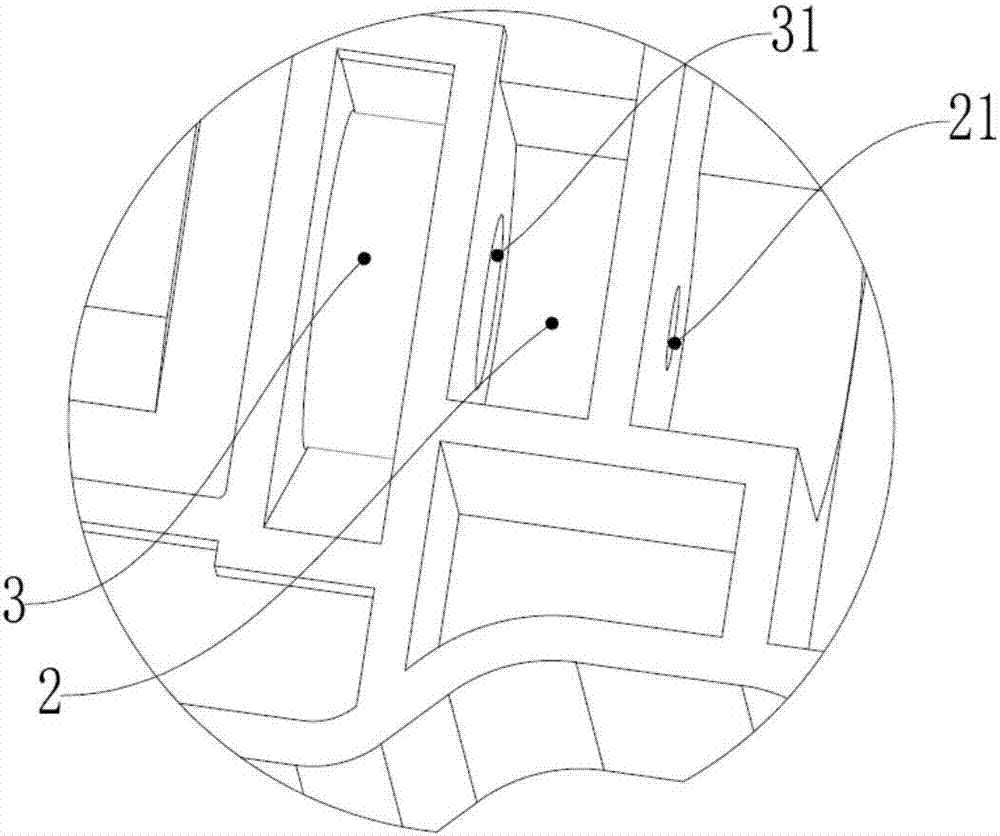

[0028] An automatic liquid replenishing device for a small chamber of a dishwasher dispenser, comprising a large chamber 1, a small chamber 2 and a temporary chamber 3 formed by welding the face shell and the bottom shell of the dispenser, the large chamber 1 communicates with the small chamber 2 , the temporary cavity 3 is arranged on one side of the small cavity 2; one side of the temporary cavity 3 is provided with a driving mechanism 4, and the driving mechanism 4 includes a driving device 41, a support rod 42, a buckle 43 and a valve Core sealing ring 44, the drive device 41 is arranged on the bottom shell, one end of the support rod 42 is connected to the drive device 41, and the other end of the support rod 42 passes through the small cavity 2 and the temporary cavity 3. The buckle 43 is set on the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com