Garment steamer hanger with independent-motion steam nozzle

A self-moving steam nozzle technology, applied in the field of garment ironing machines, can solve the problems of cumbersome, laborious and slow speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail through the examples below, so that those skilled in the art can implement it with reference to the description.

[0031] It should be understood that terms such as "having", "comprising" and "including" used herein do not exclude the presence or addition of one or more other elements or combinations thereof.

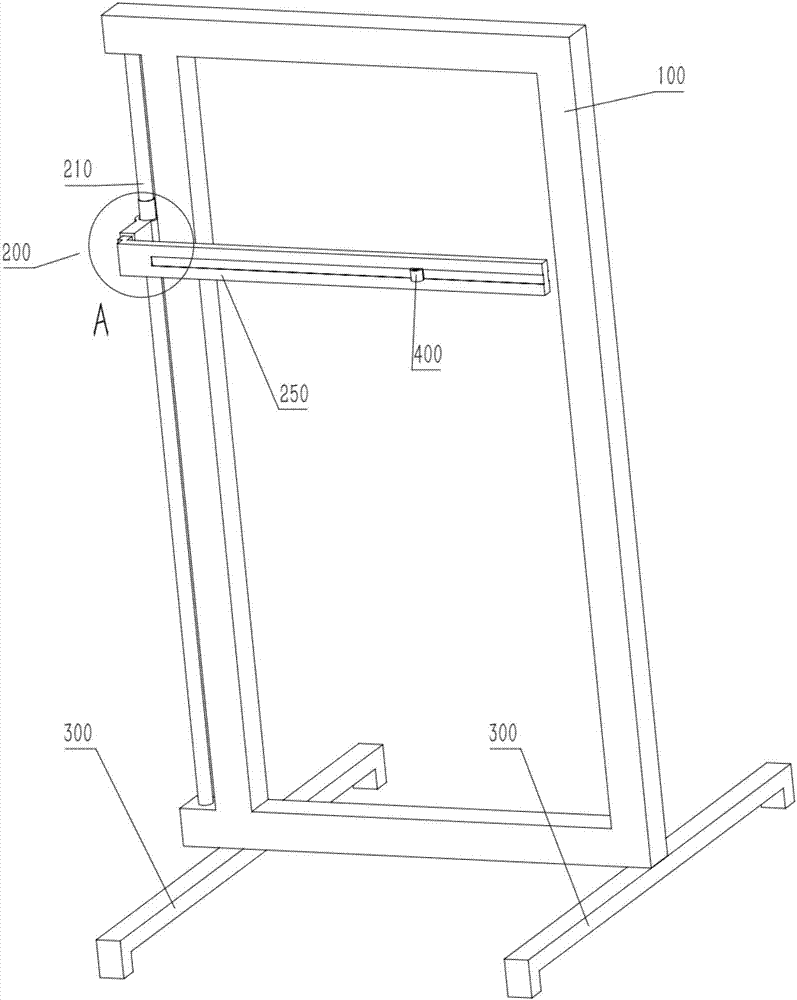

[0032] combine Figure 1-4 As shown, there are the following examples:

[0033] A clothes hanger for a clothes steamer with a self-moving steam head, comprising:

[0034] frame body 100, which is a rectangular frame structure; and

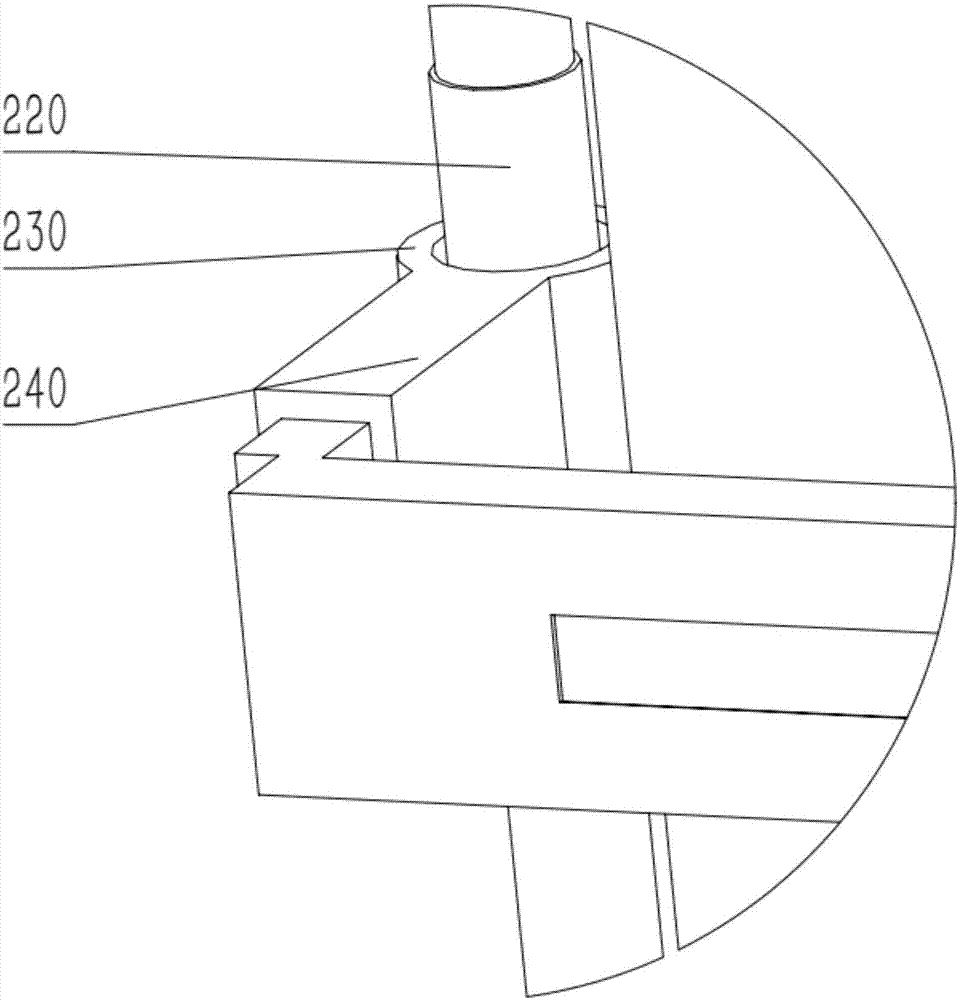

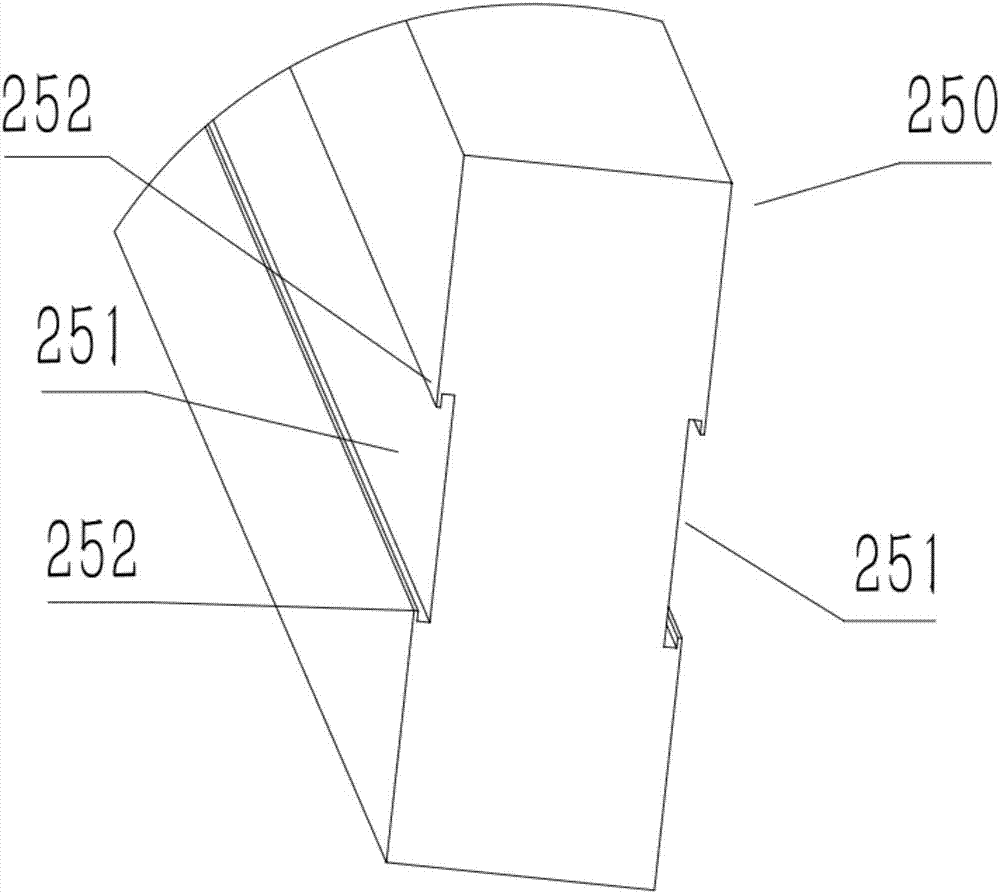

[0035] The rotating mechanism 200 includes a rotating shaft 210 vertically fixed on one side of the frame body 100. The rotating shaft 210 is provided with a lifting platform 220 that can move up and down. The table 220 is a turntable 230 that rotates around the axis, and the turntable 230 is fixedly connected to one end of a telescopic arm 240 arranged horizontally, and the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap