Testing and loading device for pure shear on shear type link beam

A technology of loading device and energy-dissipating beam, which is applied in the direction of applying stable shear force to test the strength of materials, measuring devices, instruments, etc. Problems such as pure shear force performance and uneconomical performance of shear-type energy-dissipating beams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

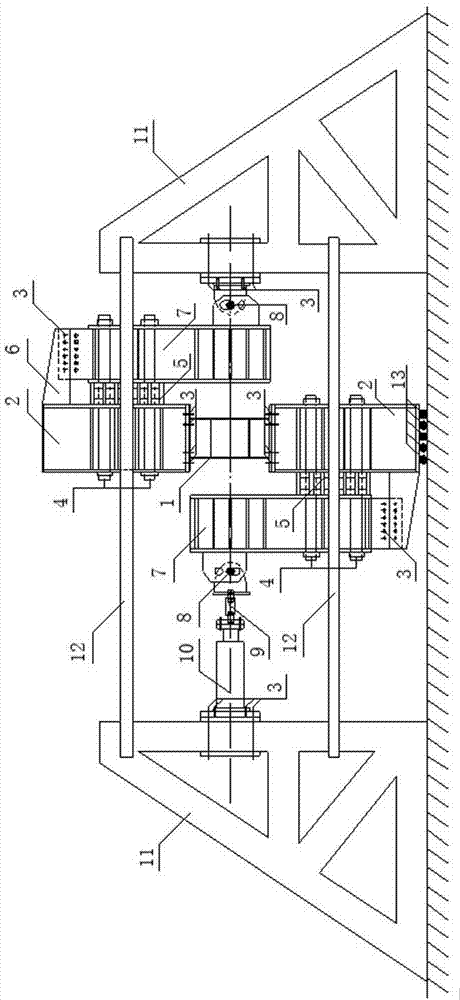

[0007] Such as figure 1 As shown, the technical solution adopted by the present invention to solve this technical problem is: arrange the entire loading device symmetrically with respect to the center of the shear-type energy-dissipating beam section, so as to ensure that the shear-type energy-dissipating beam section is subjected to pure shear force. The shear-type energy-dissipating beam section and the frame beam are designed separately, and the shear-type energy-dissipating beam section and the frame beam are connected by high-strength bolts, so that the independent loading of the shear-type energy-dissipating beam section can be realized, and shearing beam sections of different specifications can be replaced. Type energy-dissipating beam segment specimens.

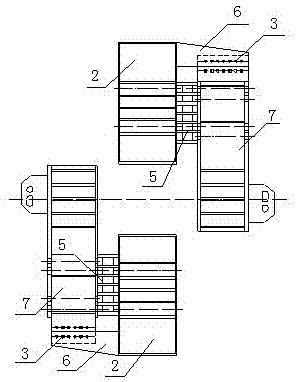

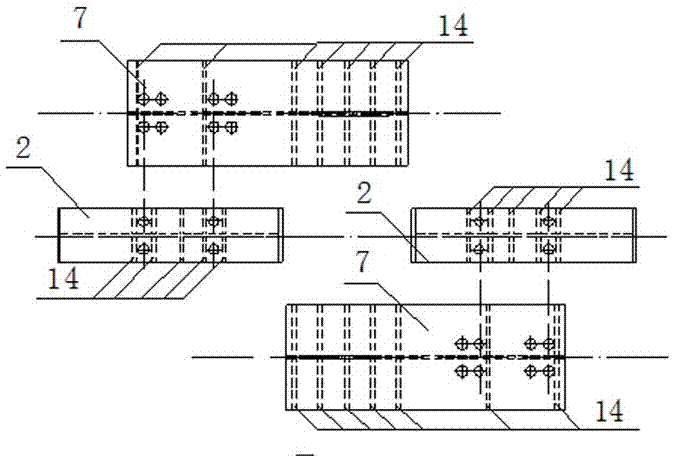

[0008] Such as figure 1 , figure 2 , image 3 As shown, the shear-type energy-dissipating beam section is subjected to pure shear test loading device. The whole test device is divided into four parts: the first pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com