Cylindrical spring test fastening method

A technology of cylindrical spring and center of circle, which is applied in the direction of elastic testing, testing of mechanical components, testing of machine/structural components, etc. It can solve the problems of inconvenient adjustment and small application range of spring testers, and achieve simple structure, ingenious design, The effect of high application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

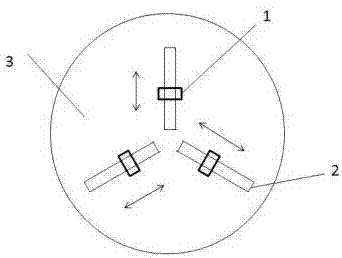

[0010] A cylindrical spring fastening method for a cylindrical spring tester. Starting from the center of a base 3, there are three radially equidistant linear slide rails 2, and each slide rail 2 has a slider 1 that can adjust its position arbitrarily. , each slide rail 2 is engraved with the scale line of the distance from the center of the base for preliminary adjustment of the position of the slider 1, and each slider 1 is engraved with the scale line of the distance from the center of the base for preliminary adjustment Adjust the position of slider 1, each slider 1 has a regular hexagonal hole vertically penetrating from top to bottom, and each hole is inserted into a regular hexagonal cylinder. When in use, first adjust the position of the slider 1 according to the radius of the cylindrical spring, and then initially fix it, then insert the cylinder, insert the cylindrical spring into the triangle formed by these cylinders, and then adjust the position of the slider 1 ap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com