Robot welding quick-change tool

A robot welding and tooling technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as inability to adapt to large-scale welding, small robot base turntable, etc., to improve welding efficiency and ensure welding quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

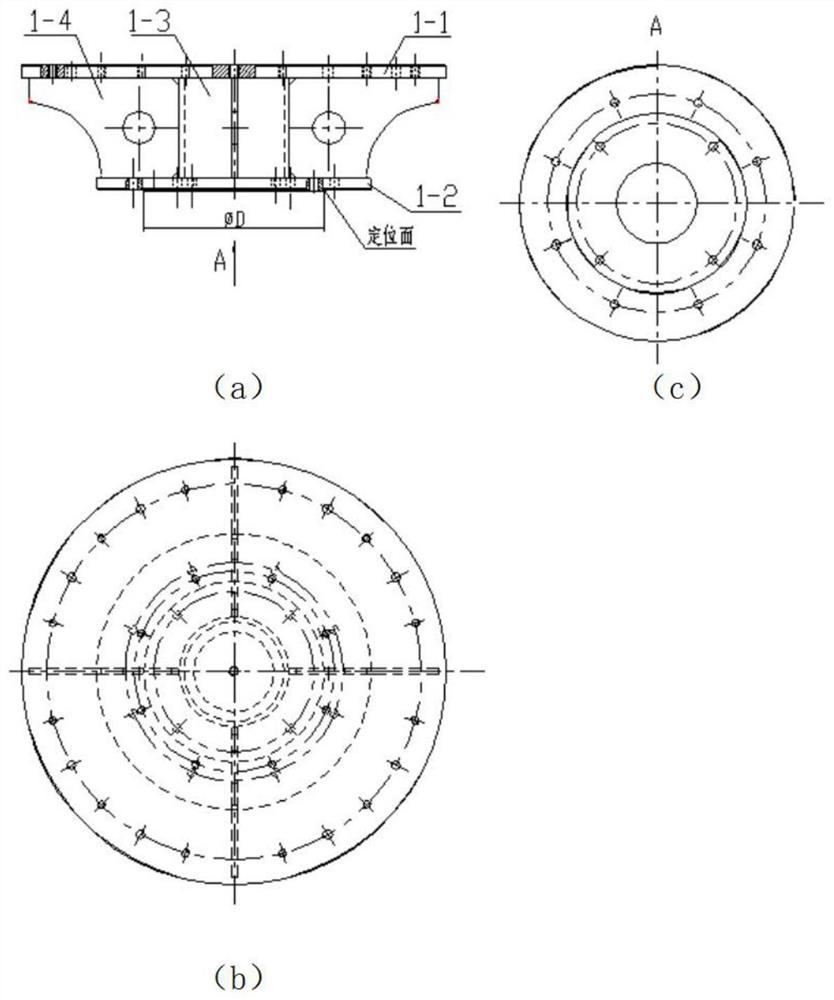

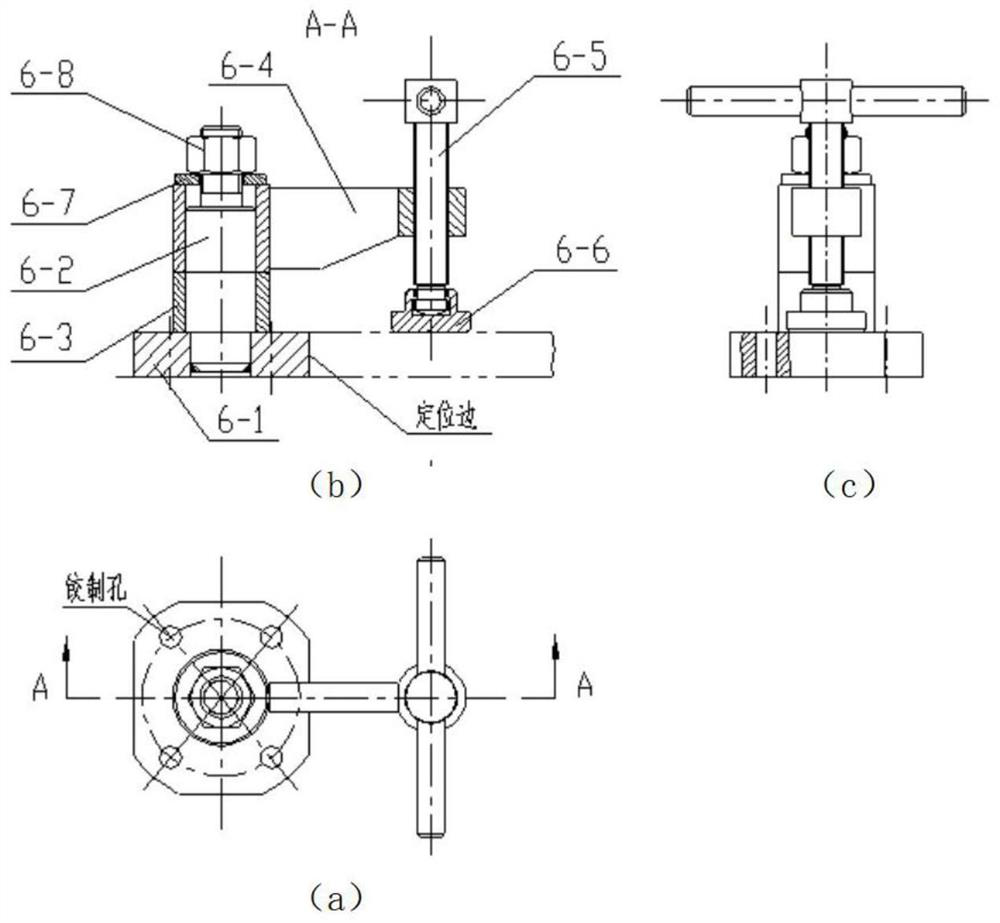

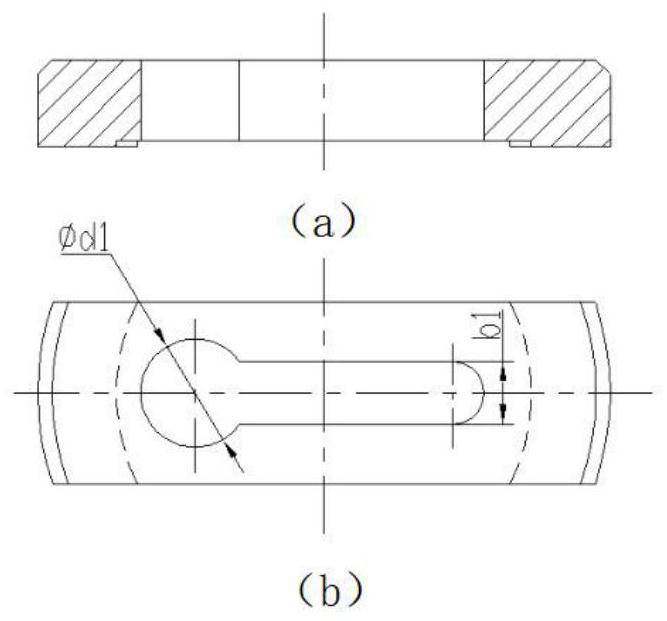

[0029] This embodiment proposes a robot welding quick change tooling, its structure is as follows figure 1 As shown, it mainly includes the transition plate assembly 1, the tooling base plate 5, the first and second rotating platen assemblies 6 and 21, the first and second quick-change platen 15 and 16, the hook platen 18 and the positioning block 24.

[0030] Such as figure 2 As shown, the transition plate assembly 1 includes a transition plate top plate 1-1, a transition plate bottom plate 1-2, a circular cylinder 1-3 and a rib plate 1-4. Wherein, the transition plate top plate 1-1 and the transition plate bottom plate 1-2 are connected by a circular cylinder 1-3 and four stiffener plates 1-4. The center position o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com