Aluminum-coated nickel cobalt-containing composite hydroxide and method for manufacturing same, cathode active material for nonaqueous electrolyte secondary battery and method for manufacturing same, and nonaqueous electrolyte secondary battery

A composite hydroxide and positive electrode active material technology, which is applied in the direction of non-aqueous electrolyte batteries, secondary batteries, nickel compounds, etc., can solve the problems of not considering the improvement of cycle characteristics and high-temperature storage, and achieve the improvement of cycle characteristics and high-temperature storage performance, improvement of battery characteristics, and large-scale industrial effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0187] (Example 1)

[0188] a) Production of Al-coated composite hydroxide

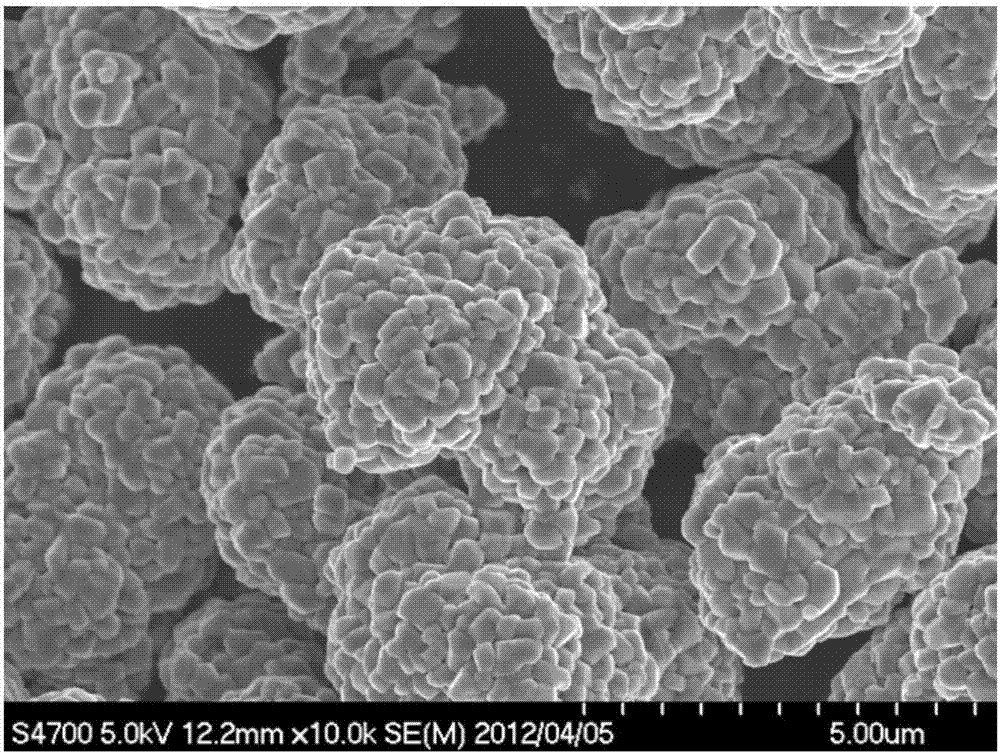

[0189] After the nickel-cobalt-containing composite hydroxide was crystallized by a batch crystallization method, the secondary particles of the composite hydroxide were coated with aluminum to produce an Al-coated composite hydroxide.

[0190] First, nickel sulfate, cobalt sulfate, and magnesium sulfate were dissolved in pure water to prepare 247L of a raw material aqueous solution with a nickel concentration of 1.65 mоl / L, a cobalt concentration of 0.31 mоl / L, and a magnesium concentration of 0.02 mоl / L. At the same time, by supplying 140 L of pure water, 6 L of 25 mass% sodium hydroxide aqueous solution, and 6 L of 25 mass% ammonia water to the reaction tank, a reaction aqueous solution was prepared.

[0191] The temperature of this reaction aqueous solution was set to 50 degreeC, and the contact of the reaction aqueous solution and oxygen was blocked by blowing nitrogen gas upwards. In this state, while ...

Example Embodiment

[0223] (Example 2)

[0224] In the crystallization step, except that the magnesium concentration of the raw material aqueous solution was set to 0.06 mоl / L, in the same manner as in Example 1, Al-coated composite hydroxides, positive electrode active materials, and secondary batteries were obtained and tested. Evaluation. The results are shown in Table 2 to Table 4. In addition, for the following Examples 3-9 and Comparative Example 7, the evaluation results are also shown in Tables 2 to 4 in the same manner.

Example Embodiment

[0225] (Example 3)

[0226] In the crystallization step, the pH of the reaction aqueous solution was adjusted to 10.8 based on the liquid temperature of 25°C, except that the same procedure as in Example 1 was carried out to obtain Al-coated composite hydroxide, positive electrode active material, and Secondary battery and evaluated it.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com