Battery

A battery and electrolyte technology, applied in the direction of battery electrodes, lithium batteries, secondary batteries, etc., can solve problems such as difficult to obtain characteristics, and achieve the effect of improving battery characteristics, good effect, and inhibiting expansion and contraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0062] In addition, specific examples of the present invention will be described in detail with reference to the accompanying drawings. In the following examples, the corresponding reference numerals and symbols used in the above embodiments are used as they are.

[0063] (Examples 1-1 to 1-6)

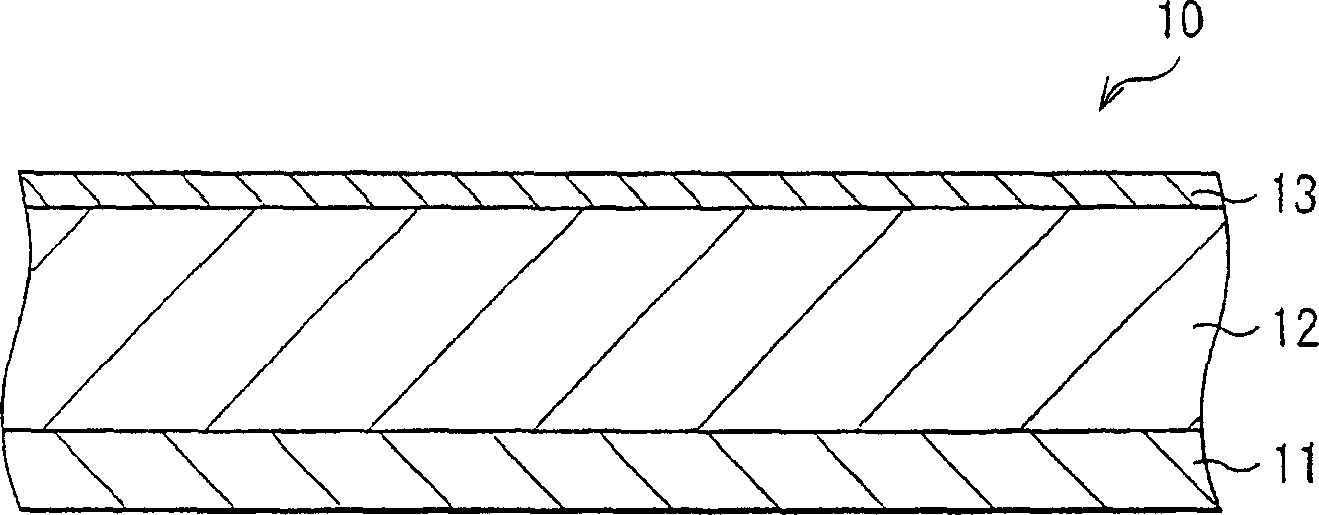

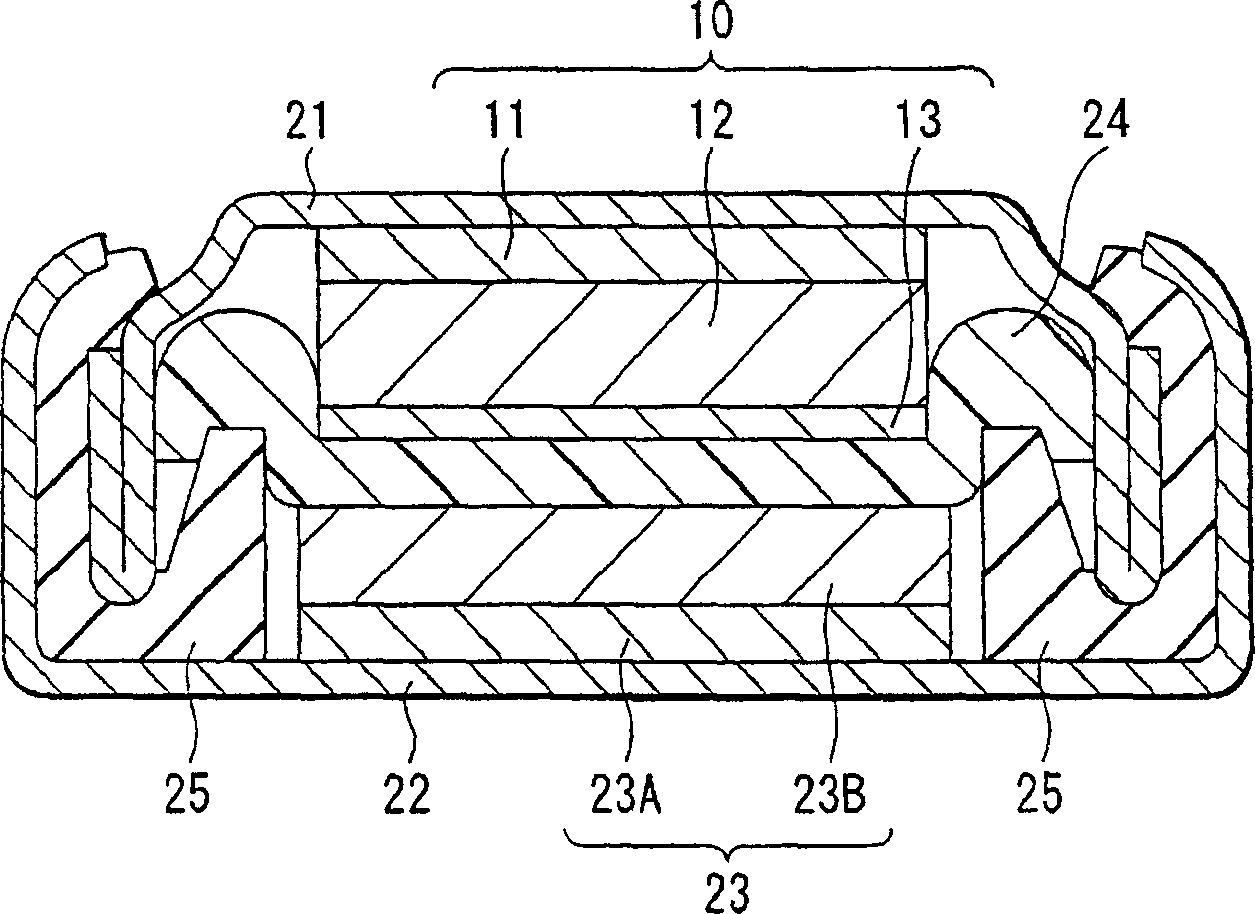

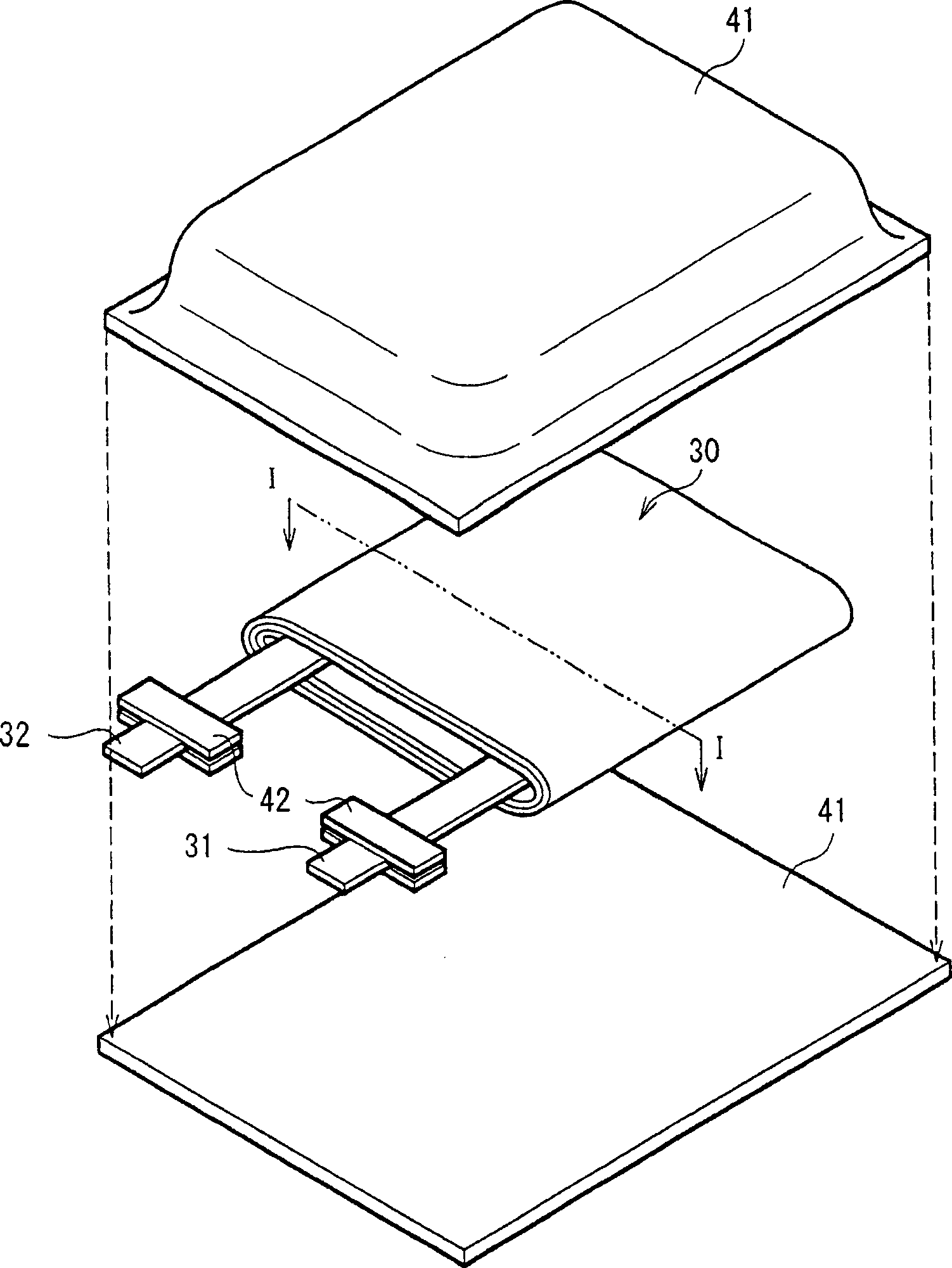

[0064] manufacture image 3 and 4 secondary battery shown. First, an anode active material layer 12 containing silicon was formed by a sputtering method using a silicon target on an anode current collector 11 made of copper foil. Then, as a discharge gas, a mixed gas of argon and oxygen is used at the beginning of deposition up to half the thickness of the anode active material layer 12, and then argon is used. The flow rate of the discharge gas is kept constant at 50cm 3 / min, and the ratio of the oxygen flow rate during the initial deposition period was changed in Examples 1-1 to 1-6.

[0065] In addition, lithium cobaltate (LiCoO) with an average particle size of 5 μm as the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com