Colloidal particle reaction cracking kettle

A pyrolysis kettle and reaction technology, applied in the field of colloidal particle pyrolysis treatment equipment, can solve the problems of bending, the rotating shaft and the heat medium cylinder can not work normally, the heat medium cylinder and the rotating shaft are easy to elongate, etc. deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

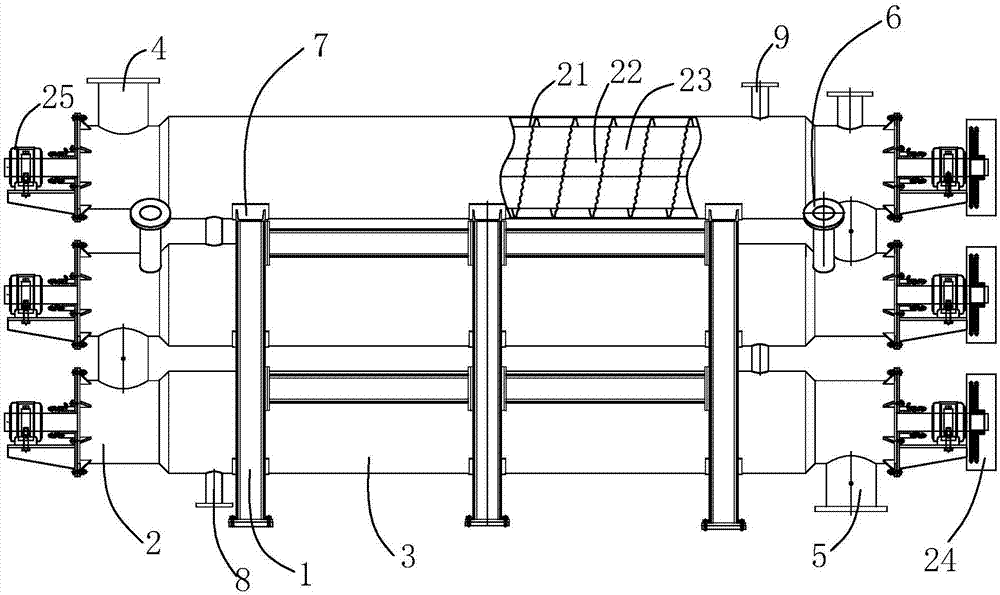

[0050] Embodiment 1: a kind of micelle reaction cracking kettle, as figure 1 As shown, it includes a frame 1 and three stages of cracking devices installed on the frame 1 connected in series, and each stage of cracking device includes a conveyor 2 and a heat medium cylinder 3 .

[0051] One end of the conveyor 2 is provided with a feed port 4, and the other end is provided with a discharge port 5. The feed port 4 of the first-stage cracking device is used to feed colloidal particles, and the discharge port 5 of the first-stage cracking device is connected to the second-stage cracking device. The feed port 4 of the first-stage cracking device is connected, the discharge port 5 of the second-stage cracking device is connected with the feed port 4 of the third-stage cracking device, and the discharge port 5 of the third-stage cracking device is used to output the cracking residue. The second-stage cracking device is provided with an oil and gas outlet 6, through which the oil and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com