Differential flowmeter

A flowmeter and differential pressure technology, which is applied in the fields of differential pressure flowmeter, flow measurement, and detection, can solve problems such as difficulty in guaranteeing linearity, interference, and complex structure, and achieve the effects of self-compensation for external influences, high precision, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

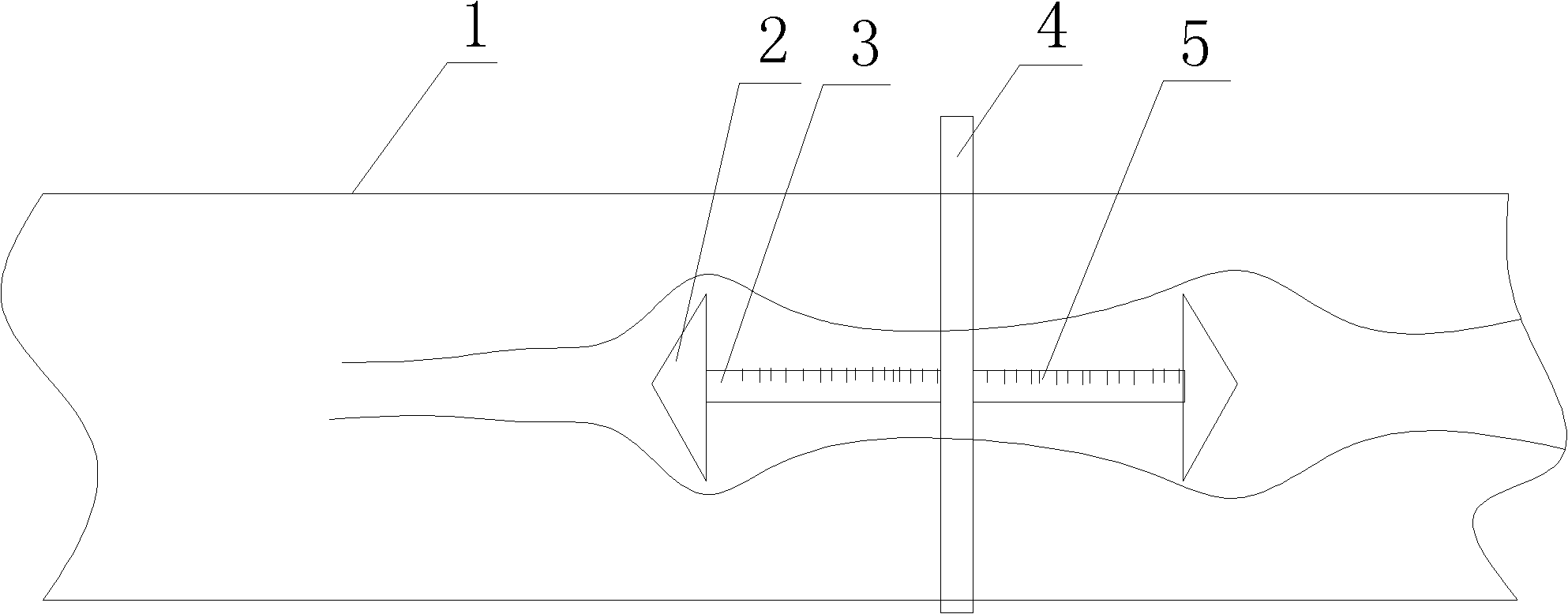

[0014] Such as figure 1 As shown, a differential pressure flowmeter includes a fixed rod 4 that passes through the diameter of the liquid flow tube 1 and is fixed to the tube. There are two opposite identical umbrella-shaped structures, the two umbrella-shaped structures are made up of cones 2 and supporting cylinders 3, and their structural dimensions are the same, and the two supporting cylinders 3 are provided with Fiber Bragg grating 5 with the same parameters, two fiber Bragg gratings 5 with the same parameters, are processed by ultraviolet engraving on one optical fiber with a certain distance in space. After the optical fiber leads out of the liquid flow tube 1, it is connected to the strength demodulator (light source, optocoupler, photoelectric conversion circuit), and then connected to the data processing device.

[0015] The fixed rod 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com