Aluminum alloy inward-opening window

A technology of inward opening windows and aluminum alloys, which is applied in windows/doors, window glass installation, building components, etc., can solve problems such as the influence of building insulation performance and obstacles to energy saving and emission reduction of houses, so as to increase the performance of heat insulation and heat preservation. Sealing performance, material saving, convenient installation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

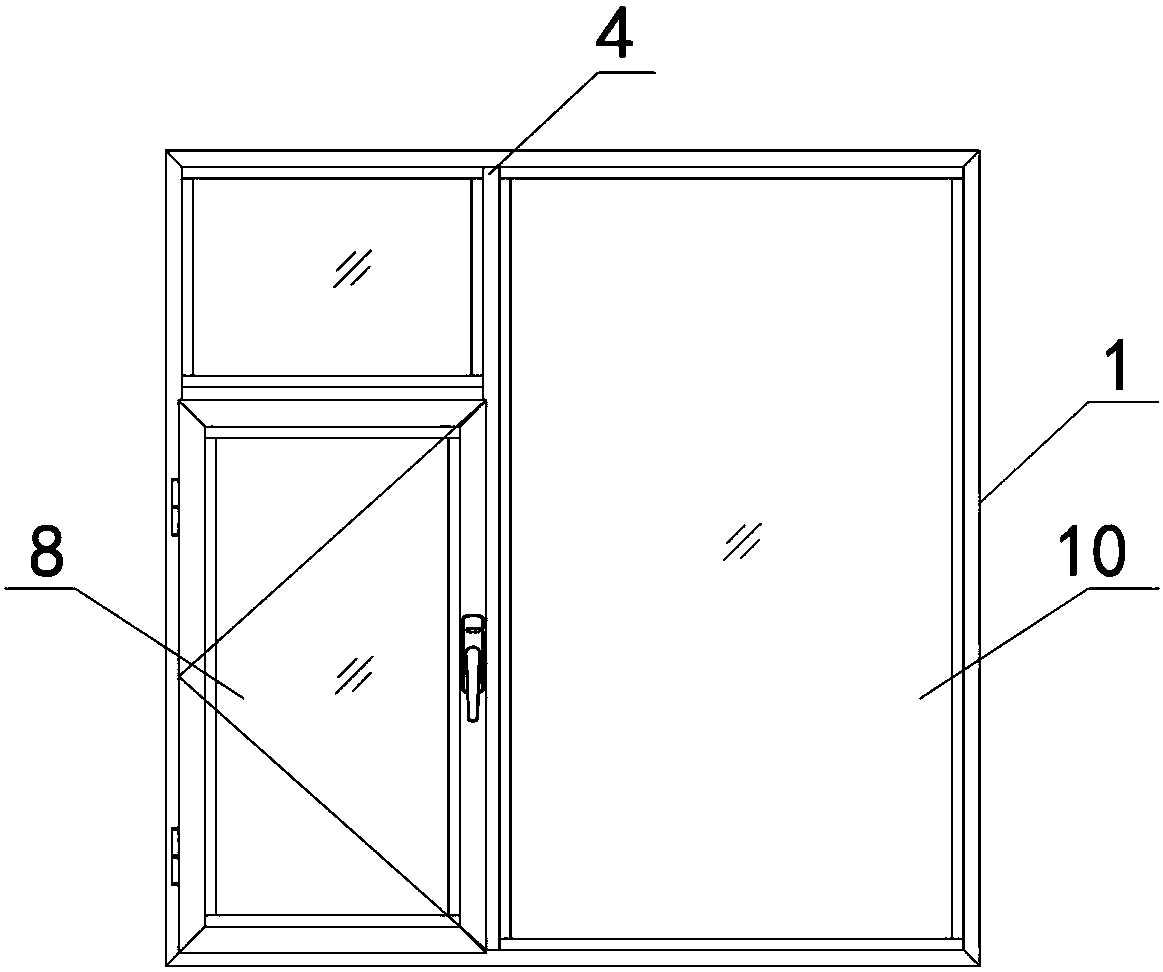

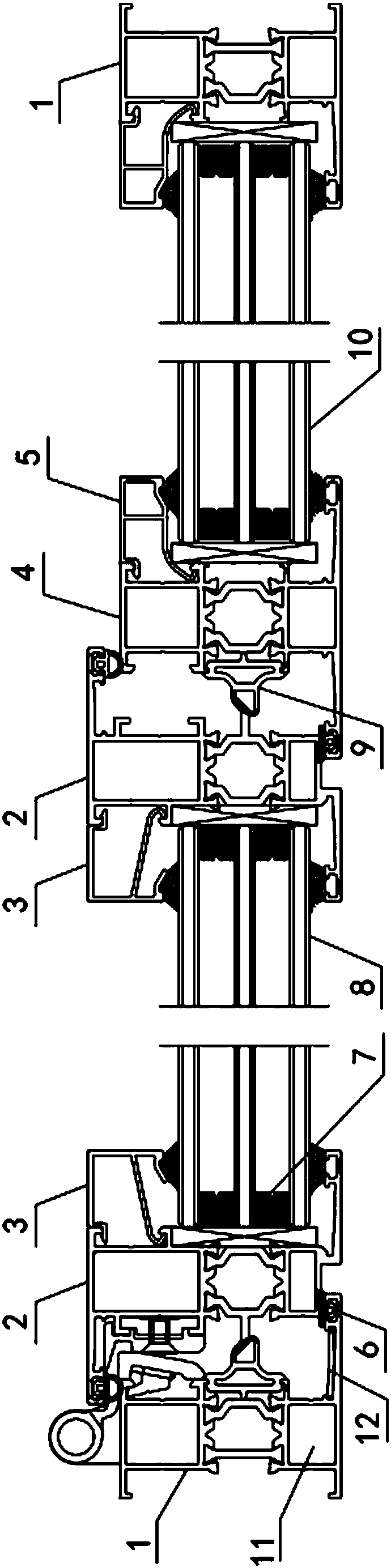

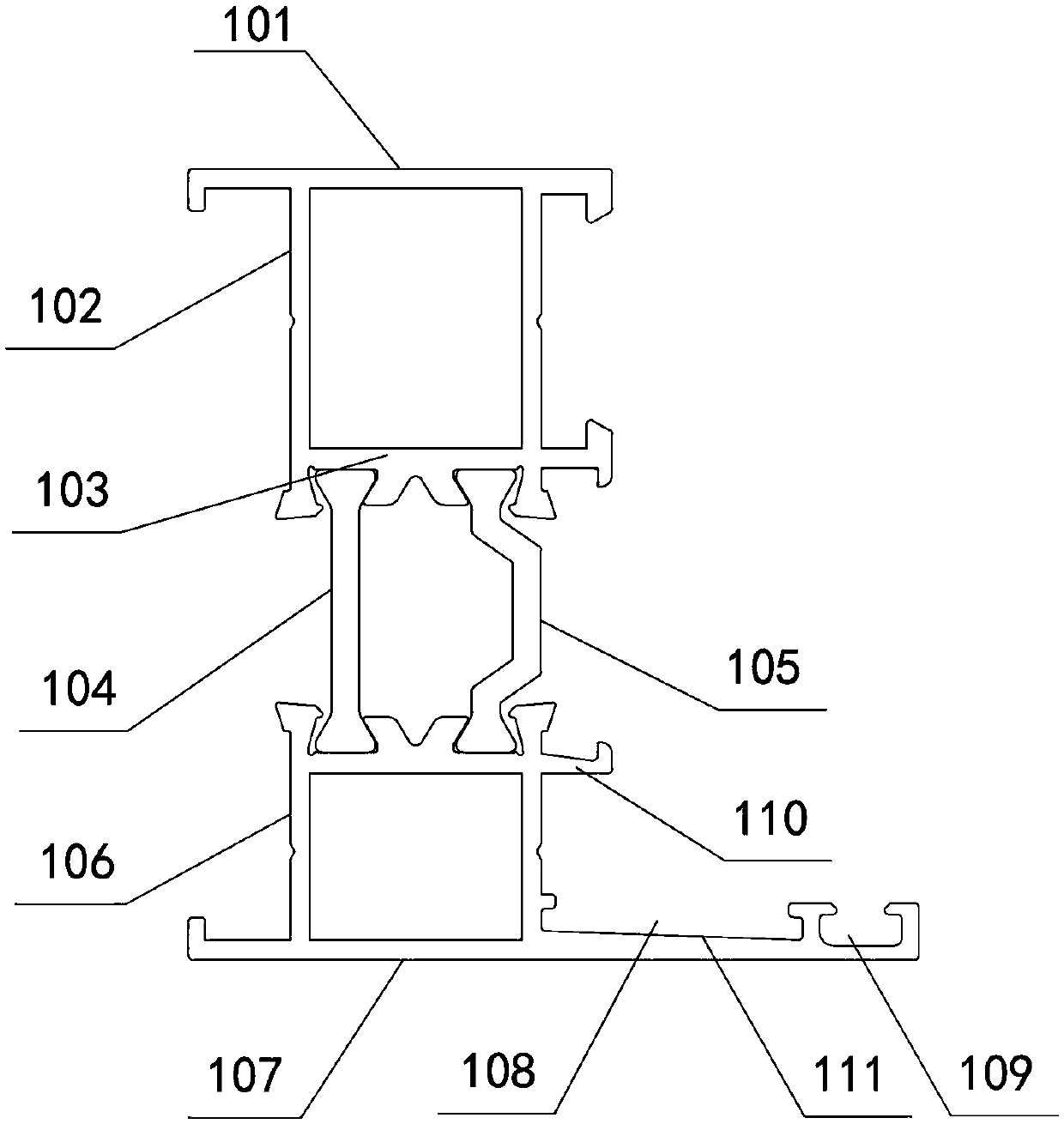

[0033] Such as figure 1 , figure 2 As shown, the present invention provides an aluminum alloy inner window, comprising a frame 1, an inner fan is arranged in the frame 1, and the inner fan includes an inner fan frame 2, an inner fan glass 8 and an inner fan pressing line 3, and The fan glass 8 is arranged on the inner fan frame 2 through the inner fan pressing line 3 . The inner opening glass 8 is a three-layer glass structure; the frame 1 and the inner opening frame 2 are both split structures, and the middle part of the cross-section is respectively formed by heat insulation elements to form a frame heat insulation bridge and an inner fan frame heat insulation bridge, and the frame The heat insulation bridge and the heat insulation bridge of the inner fan frame are located between the inner glass and the outer glass of the inner fan glass, forming an isothermal layer.

[0034]In the prior art, the outside of the inner sash of the inner sash has a protruding edge. Because ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com