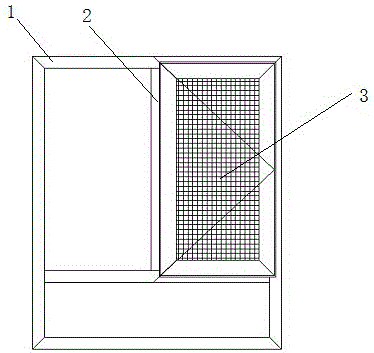

Aluminum alloy out-opening window

A technology for outward opening windows and aluminum alloys, which is applied in the field of aluminum alloy products, can solve the problems of thermal insulation performance, energy saving and emission reduction obstacles of aluminum alloy windows and houses, and affecting the sealing performance of windows, so as to save materials, increase thermal insulation performance and The effect of sealing performance and versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

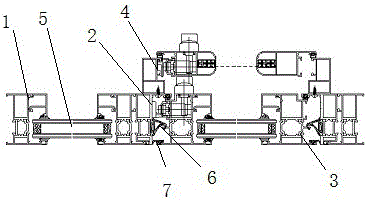

Method used

Image

Examples

Embodiment Construction

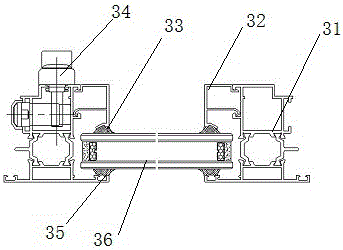

[0041] In order to further illustrate the technical scheme of the present invention, the specific implementation manner of the present invention is illustrated in conjunction with accompanying drawing now; Figure 12 , select rubber material as the manufacturing material of edge sealing strip 7 in this example, select the peripheral wall thickness of mounting body 71 to be 1.3 millimeters, and its internal cavity area is 1.6 millimeters * 1.8 millimeters; Select the thickness of sealing edge 72 to be 1.3 millimeters, The length is 10 mm; the length of the selected lip 73 is 6 mm, the thickness of the root is the same as that of the sealing edge 72, the thickness of the end is 0.5 mm, and the width of the card slot is 0.8 mm and the depth is 2 mm. According to the above-mentioned cross-sectional size and shape, make Mold, it is processed into strip shape, has just finished the implementation of edge sealing strip 7 like this; Due to the effect of lip 73, when opening fan 3 is cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com