Aluminum alloy outer-opening window

A technology of outward opening windows and aluminum alloys, applied in windows/doors, building components, buildings, etc., can solve the problems of difficult profile manufacturing, troublesome construction, waste of profiles, etc., to increase thermal insulation performance and sealing performance, installation and use. Convenience and material saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

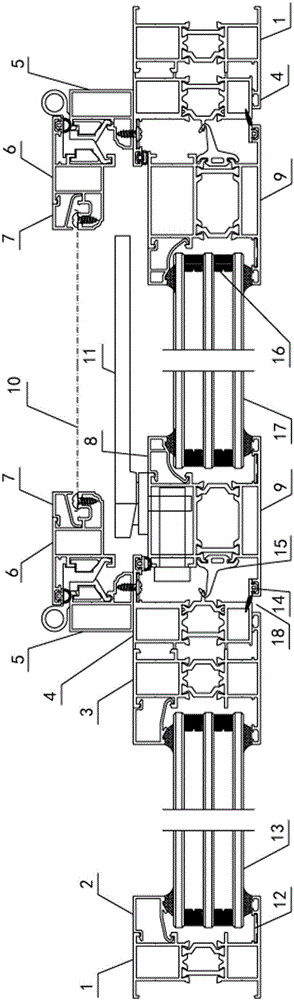

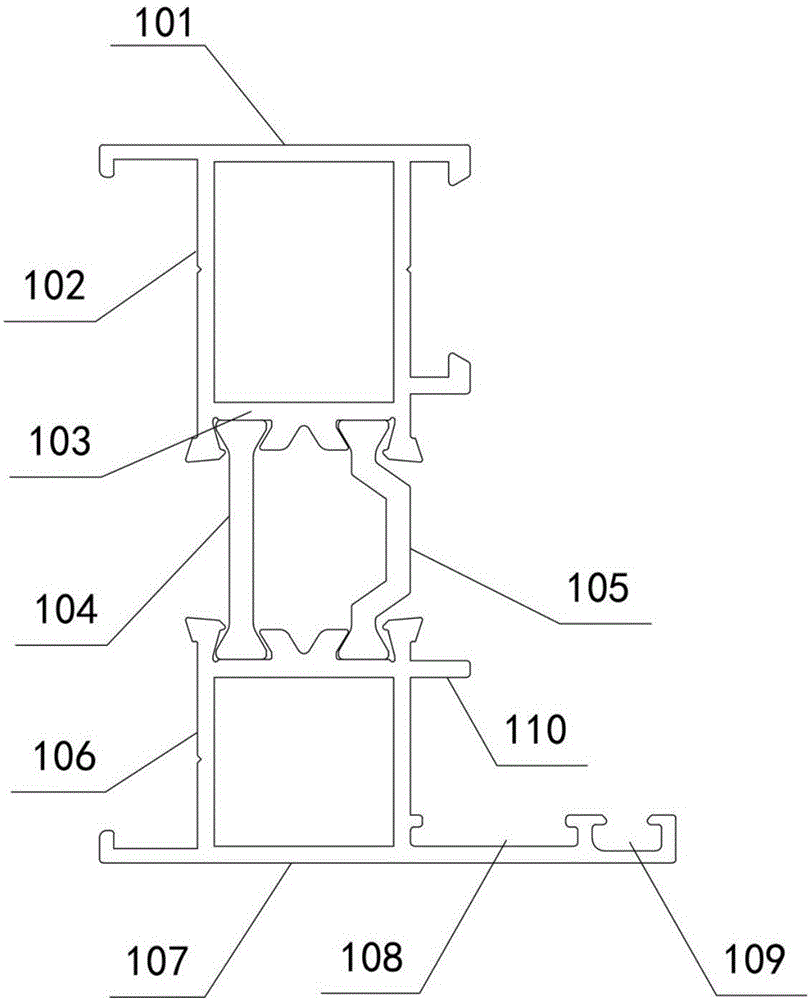

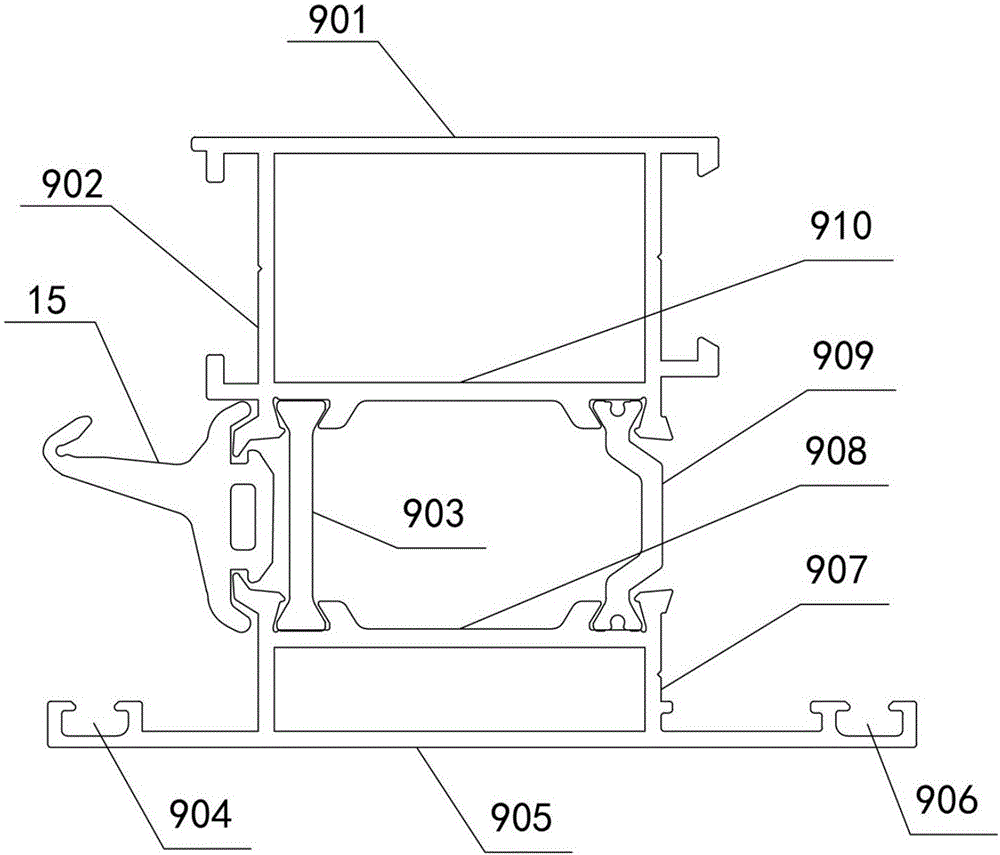

[0052] Such as figure 1 , Figure 14 As shown, the present invention provides an aluminum alloy outward opening window, comprising an outward opening frame 1, a middle stile 3, a steering frame 4, an opening fan, a fixed fan and a screen window; The window is divided into multiple panes. The fixed fan is arranged on a window surface between the outer frame 1 and the middle stile 3, and the glass 13 of the fixed fan is arranged on the outer frame 1 through the outer frame pressure line 2. The steering frame 4 is arranged on another window between the middle stile 3 and the outer frame 1 . Opening fan is set in turning frame 4, and opening fan comprises opening fan frame 9, opening fan pressing line 7 and the glass 17 of opening fan, and the glass 17 of opening fan is arranged on opening fan frame 9 through opening fan pressing line 7, and opening fan frame 9 is provided with equal pressure rubber strip 15, and the suspended part of equal pressure rubber strip 15 is in contac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com