Power-generator connecting sleeve

A generator and cylindrical technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of obstructing sight, inconvenient screwing, time-consuming and laborious, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

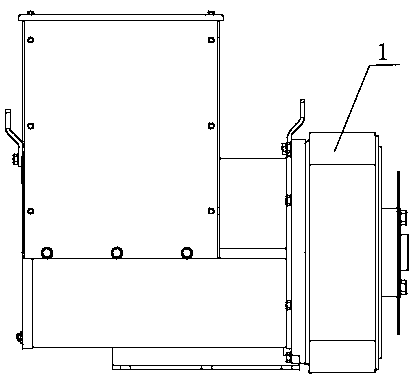

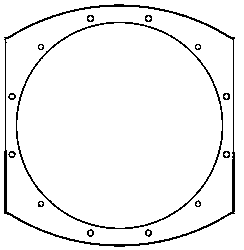

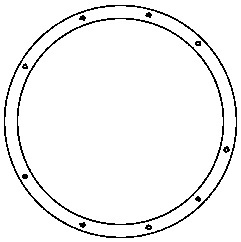

[0011] Such as image 3 The generator socket shown is cylindrical, and the middle of the generator socket 1 is provided with a through hole, and the front and rear surfaces of the generator socket 1 are also provided with screw holes and positioning pins.

[0012] When installing the socket 1, the installer first locates the socket 1 with the generator through the positioning pin, sets the socket 1 on the generator, and then fixes it with screws through the screw holes. Since the cylindrical socket 1 is used, it will not be damaged by the traditional The upper and lower parts are arc-shaped, and the left and right sides of the square adapter block the screw from being tightened, and the line of sight will not be blocked by it, which saves time and effort, and is very convenient.

[0013] The above is only a preferred embodiment of the present invention, but the scope of protection of the present invention is not limited thereto, any changes or substitutions that can be easily ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com