Predried non-film paperboard production equipment

A production equipment and pre-drying technology, applied in coating, mechanical processing/deformation, metal processing, etc., can solve the problems of insufficient cardboard strength, large pollution, poor cutting effect, etc., to increase distance and shorten transmission distance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

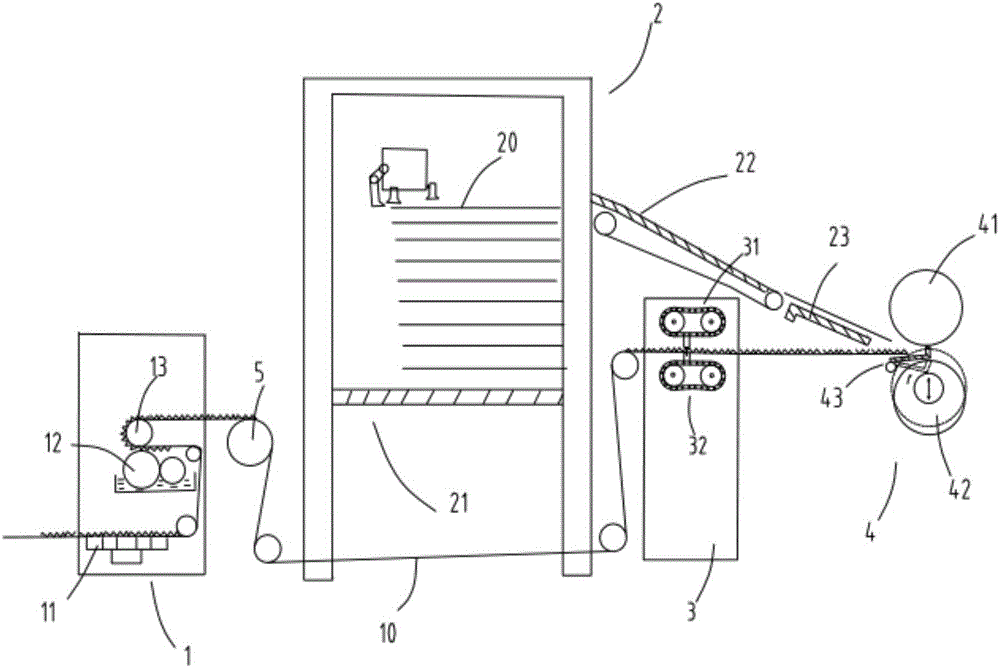

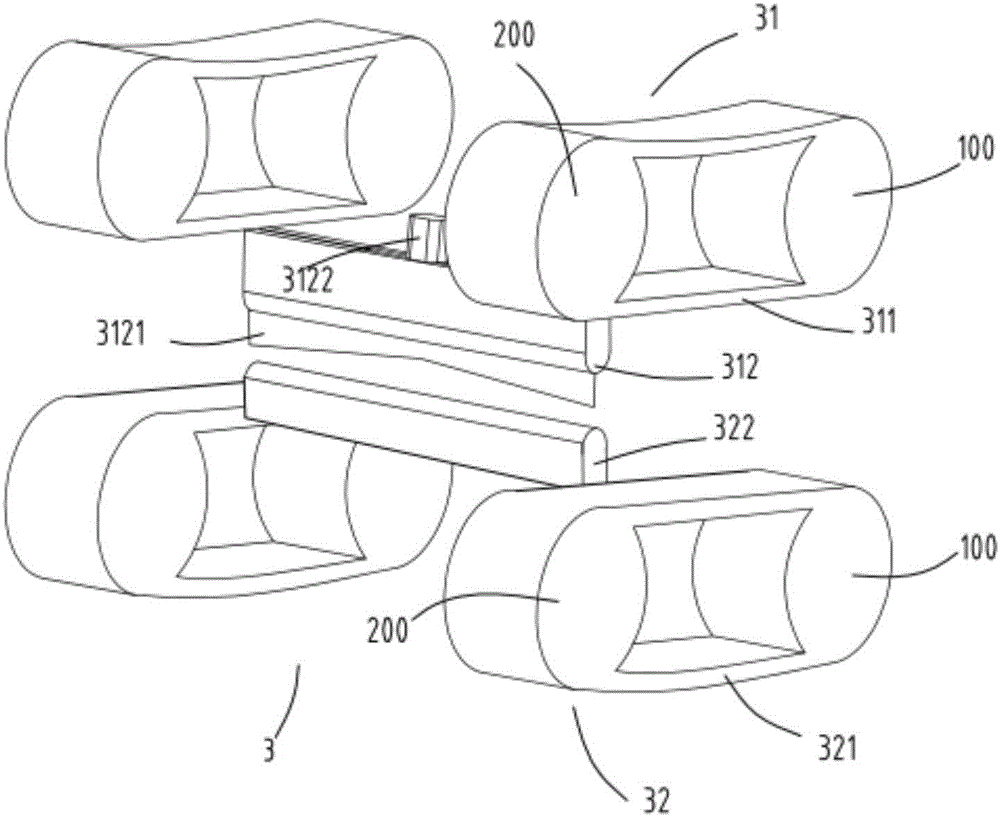

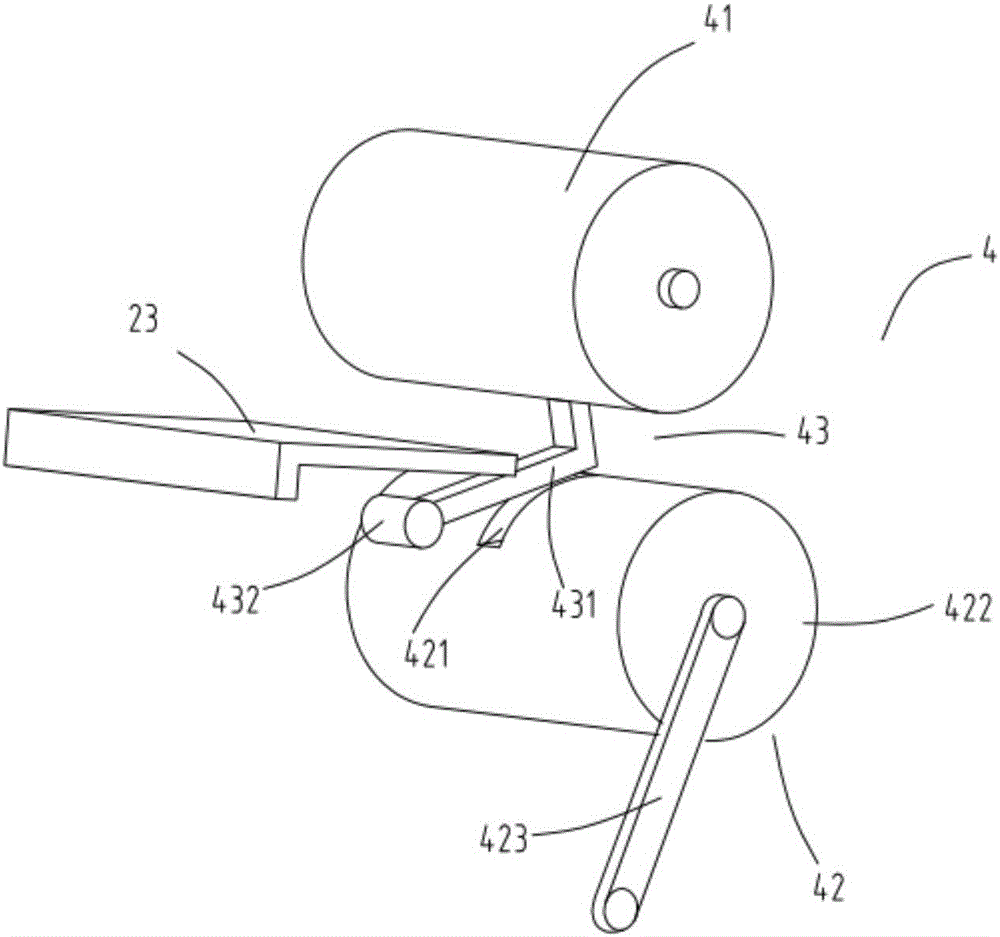

[0025] figure 1 In order to accurately cut the schematic diagram of the pre-drying filmless cardboard production equipment, figure 2 For the schematic diagram of the synchronous crosscutting machine, image 3 To locate the schematic diagram of the pressing part, Figure 4 The schematic diagram of the cutter device. Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, this embodiment provides a pre-drying filmless paperboard production equipment, including a corrugated paper pretreatment part 1, a tissue conveying part 2, a cutting device 3, and a positioning and pressing part 4; the corrugated paper pretreatment Part 1 is provided at the front end of the tissue paper conveying part 2; the cutting device 3 is provided at the rear and lower ends of the tissue paper conveying part 2; the positioning and pressing part 4 is provided at the rear end of the cutting device 3; The cutting device 3 includes an upper synchronous cutter wheel 31 and a lower synchronous suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com