Patents

Literature

33results about How to "No edge warping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

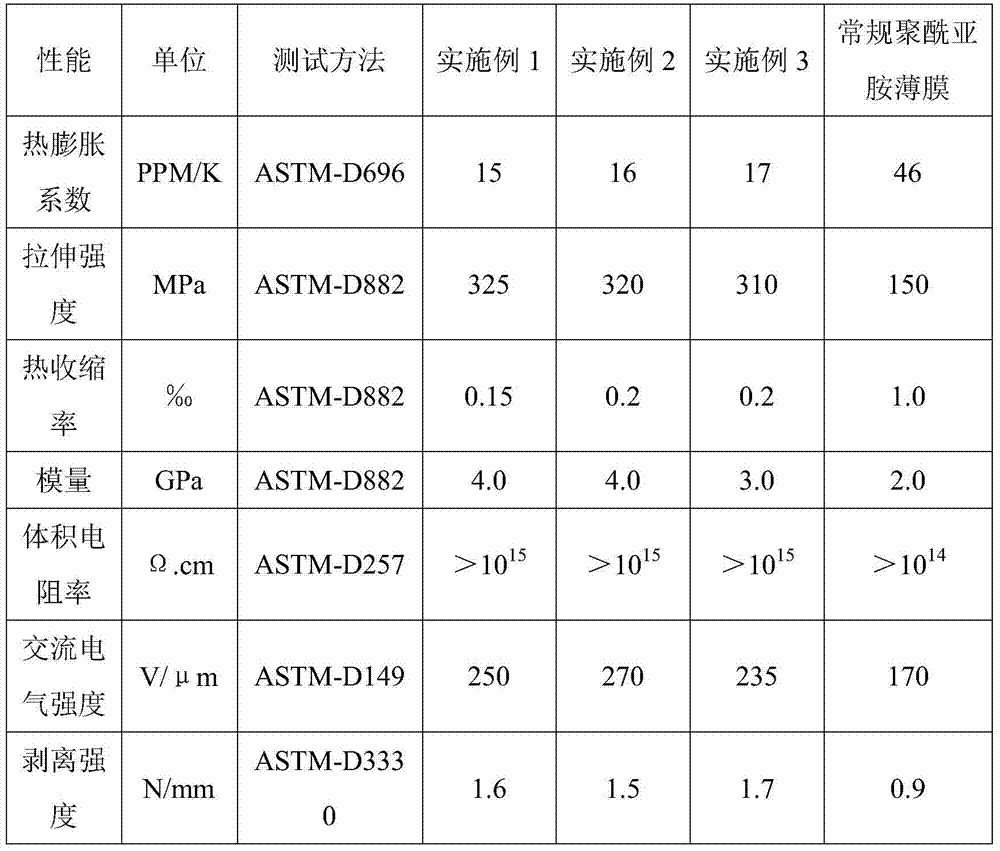

Preparation method for polymide film with low thermal expansion coefficient

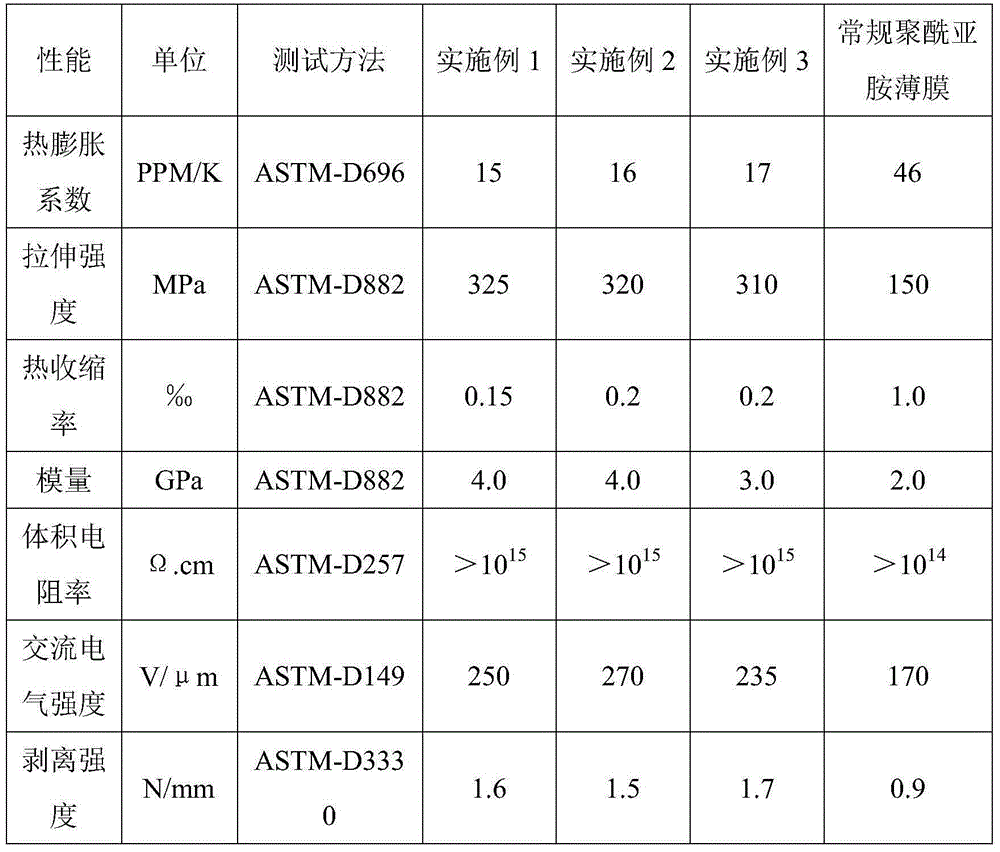

The invention provides a preparation method for a polymide film with the low thermal expansion coefficient. The method comprises the following steps that 1, pyromellitic anhydride and ursol are placed into a dimethylacetamide solvent for condensation polymerization to obtain a polyamide acid glue solution A; 2, 2, 3',3,4'- biphenyltetracarboxylic dianhydride and 4,4'-diaminodiphenyl ether are placed into the dimethylacetamide solvent for condensation polymerization to obtain a polyamide acid glue solution B; 3, the polyamide acid glue solution A and the polyamide acid glue solution B are mixed for a high-speed stirring reaction to obtain a polyamide acid glue solution C; 4, the tape casting technology is adopted on the polyamide acid glue solution C to obtain a film, and finally the film is fed into an imidization furnace to be processed to obtain the polymide film with the low thermal expansion coefficient. The CTE of the polymide film with the low thermal expansion coefficient is 15-17 ppm / K, and the polymide film further has the advantages of being high in strength, stability, electrical strength and the like.

Owner:安徽统唯新材料科技股份有限公司

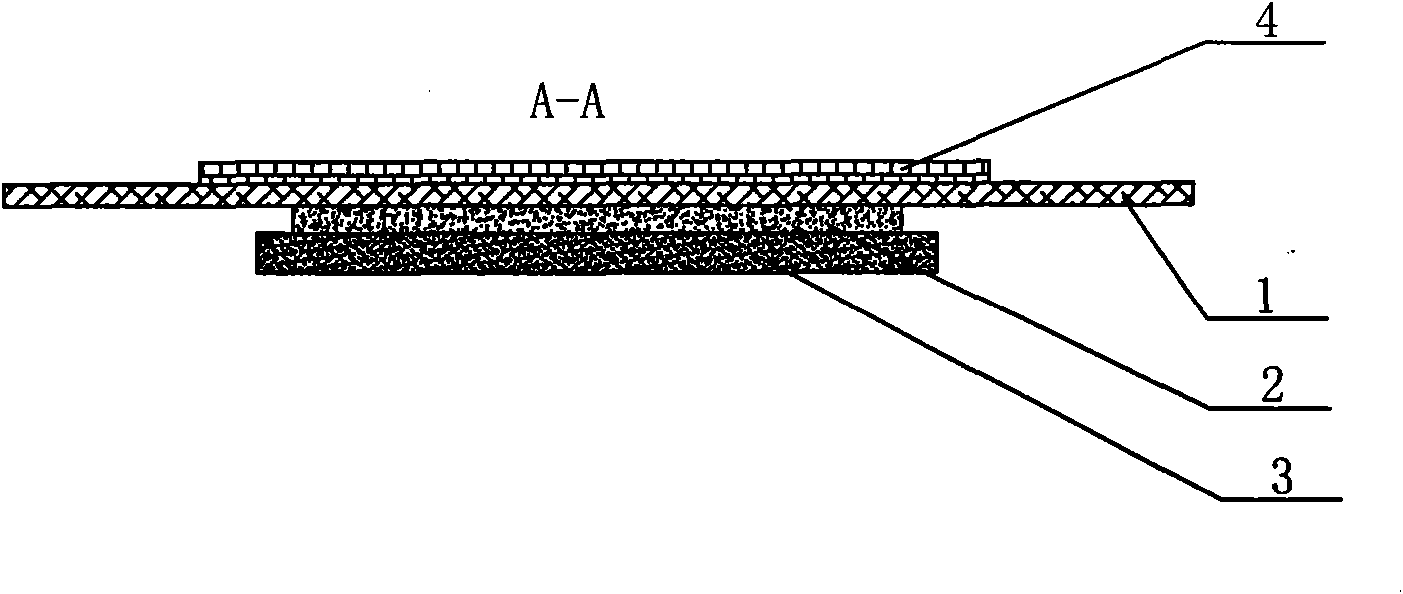

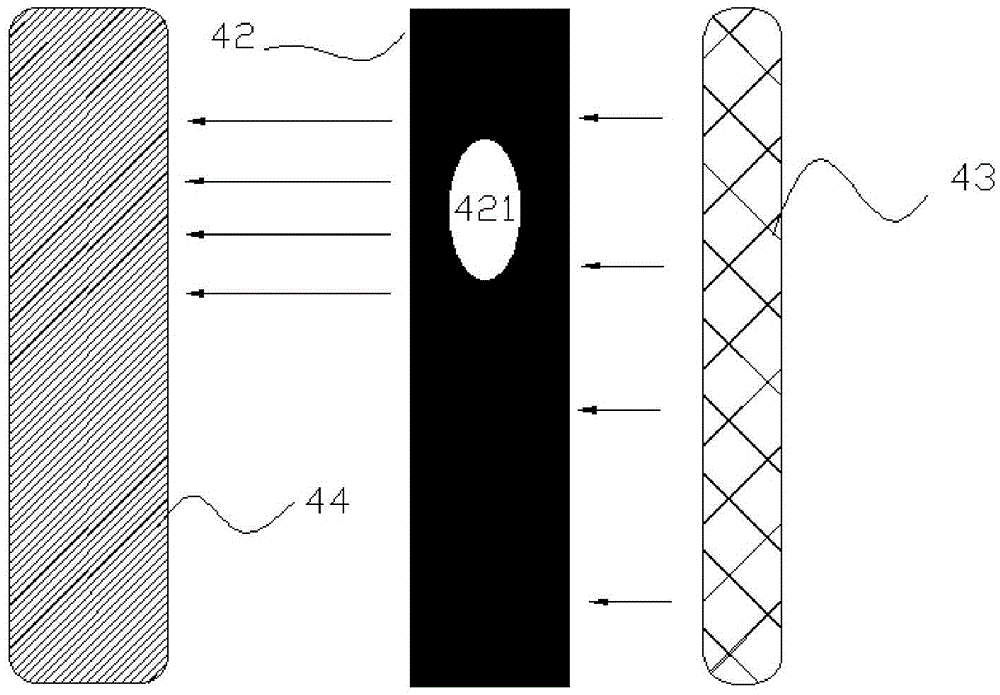

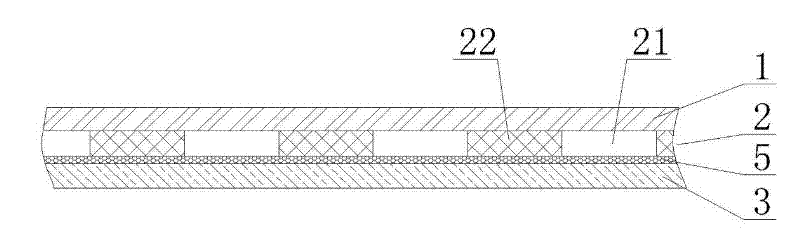

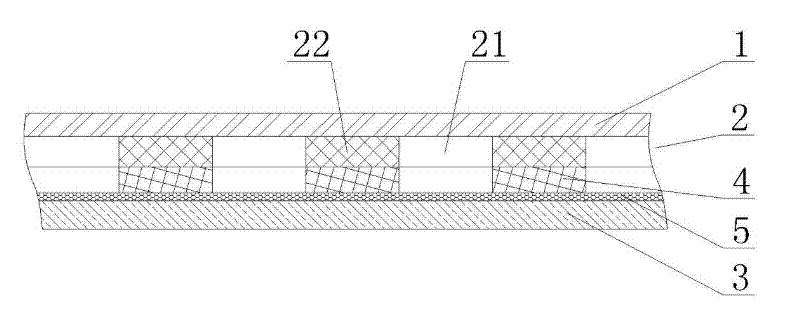

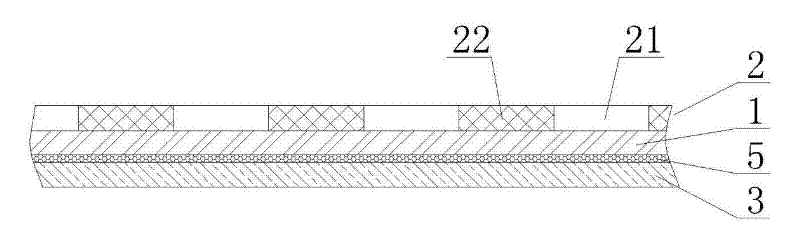

Perspective film and manufacturing method thereof

InactiveCN102152513AIncrease paste areaNo edge warpingLamination ancillary operationsLayered product treatmentEngineeringLight hole

Owner:文明华

Multifunctional protective material with high-pressure water-jet-cutting resistance and preparation method thereof

ActiveCN106280910AGood film formingStrong adhesionAnti-corrosive paintsEpoxy resin coatingsNumerical controlHigh pressure water

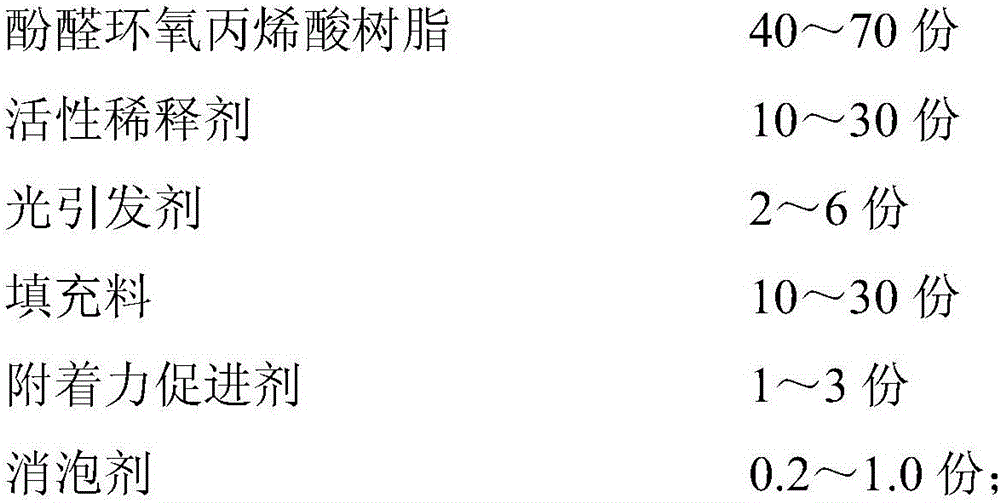

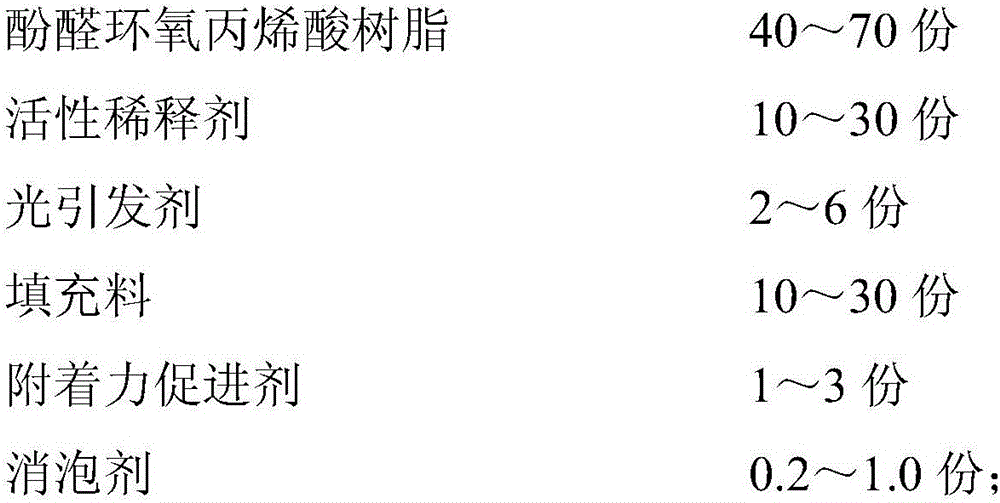

The invention belongs to the technical field of multifunctional protective materials and discloses a multifunctional protective material with high-pressure water-jet-cutting resistance and hydrofluoric-acid etching resistance and a preparation method and application thereof, especially for the machining fields of cover plates, touch screens and shells of mobile phones. The multifunctional protective material comprises the following components in parts by weight: 40-70 parts of phenolic epoxy acrylate resin, 10-30 parts of an active diluent, 2-6 parts of a photoinitiator, 10-30 parts of filler, 1-3 parts of an adhesion promoter and 0.2-1.0 part of a defoaming agent. The multifunctional protective material disclosed by the invention has the advantages that by silk-screen printing or spraying and UV curing, the obtained coating layer shows excellent adhesion on glass or metal substrates, so that the phenomena of hollowing, edge warping, dropping and the like in the processes of water-cutting scribing and CNC (Computer Numerical Control) carving process can be avoided; hydrofluoric acid with the concentration of 20% can be resisted for more than 30 minutes, so that the requirement for the protective performance can be met; due to use of environmental-friendly film dropping water, no residual film is left, and pieced dropping is achieved in film dropping; and the separation is easy, the automation degree of the process is high, and safe and environmental-friendly effects are achieved.

Owner:国科广化(南雄)新材料研究院有限公司 +1

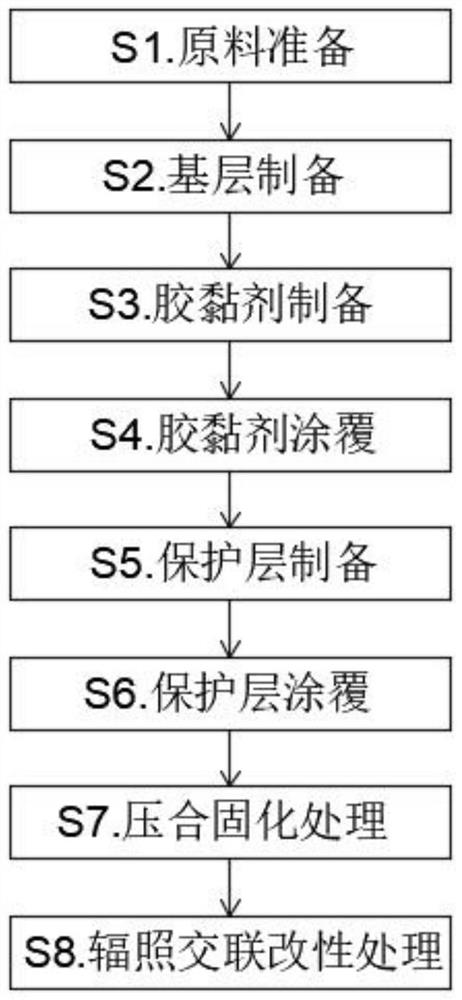

Production process of polyethylene (PE) protective film

The invention relates to the technical field of protective films, in particular to a production process of a polyethylene (PE) protective film. The PE protective film produced by the production process has high / low temperature resistance, reduces the phenomenon of warping during use, can avoid the phenomenon of degumming during peeling, and is convenient to peel. A preparation method comprises thefollowing steps of S1, film blowing: melting and plasticizing a plastic raw material in an extruder, extruding the plastic raw material into a film tube through an annular die head, and blowing, cooling and sizing the film tube with compressed air to form a PE film; S2, preparation of a pressure-sensitive adhesive: mixing water-based acrylic acid and cross-linked polyacrylic acid, adding the mixture into a fuse machine, melting and stirring the mixture uniformly to obtain an adhesive; S3, glue coating: uniformly coating the surface of the PE film with the adhesive by a coating machine; S4, curing treatment: curing the PE film coated with the adhesive by ultraviolet light irradiation; S5, irradiation cross-linking modification treatment: performing cross-linking modification treatment on asemi-finished product obtained after curing; S6, winding; and S7, slitting.

Owner:昆山恒永昌电子科技有限公司

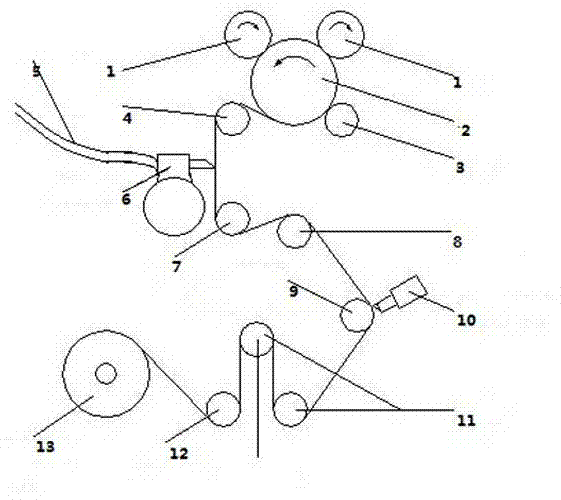

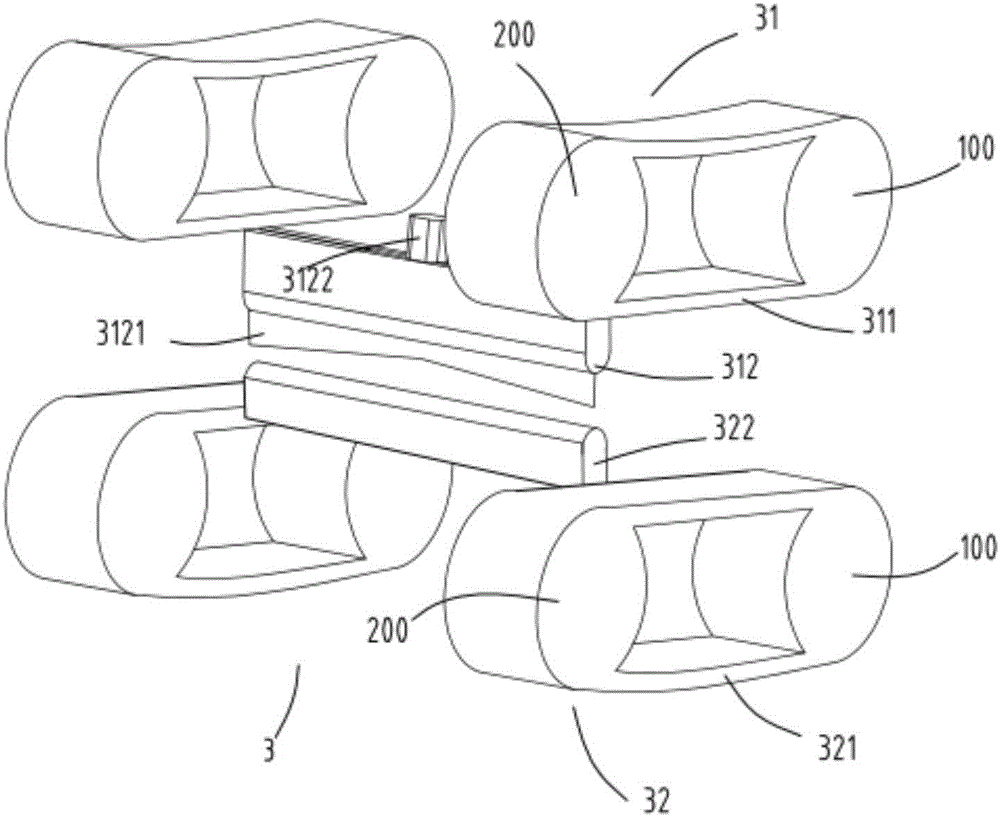

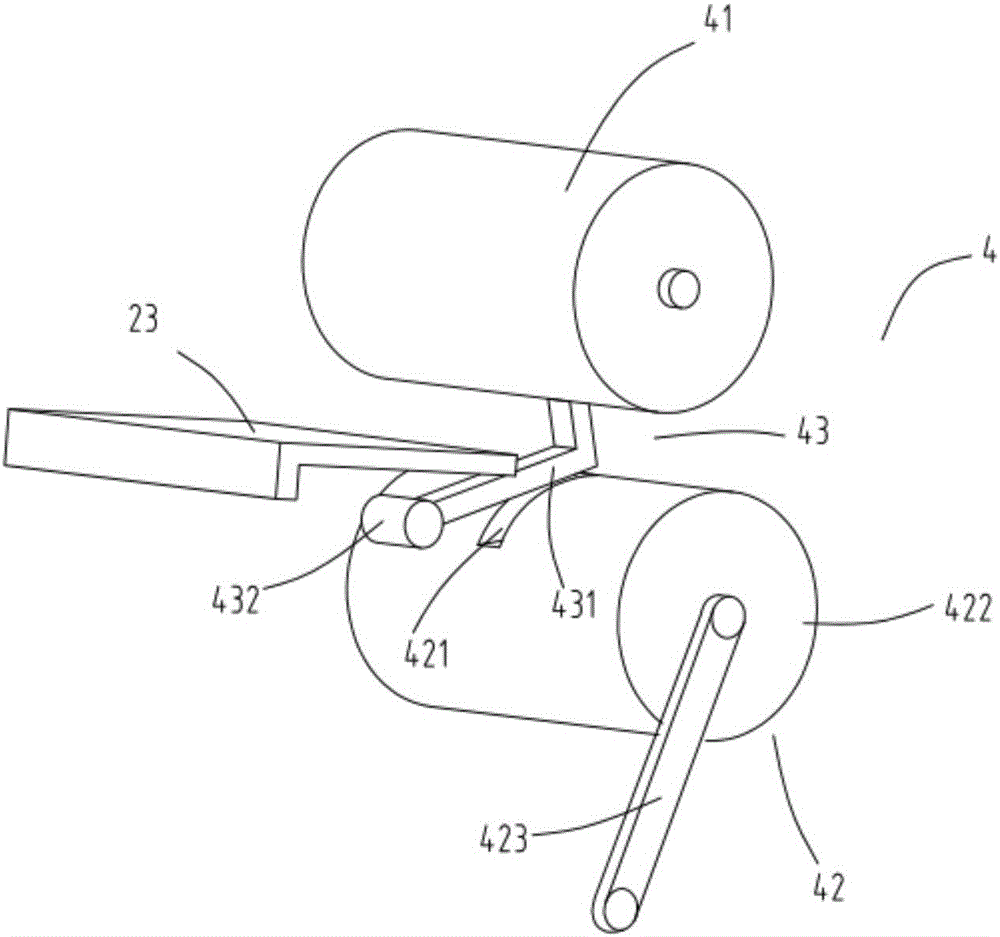

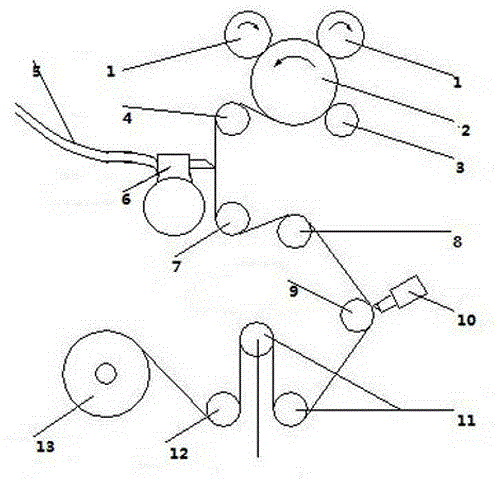

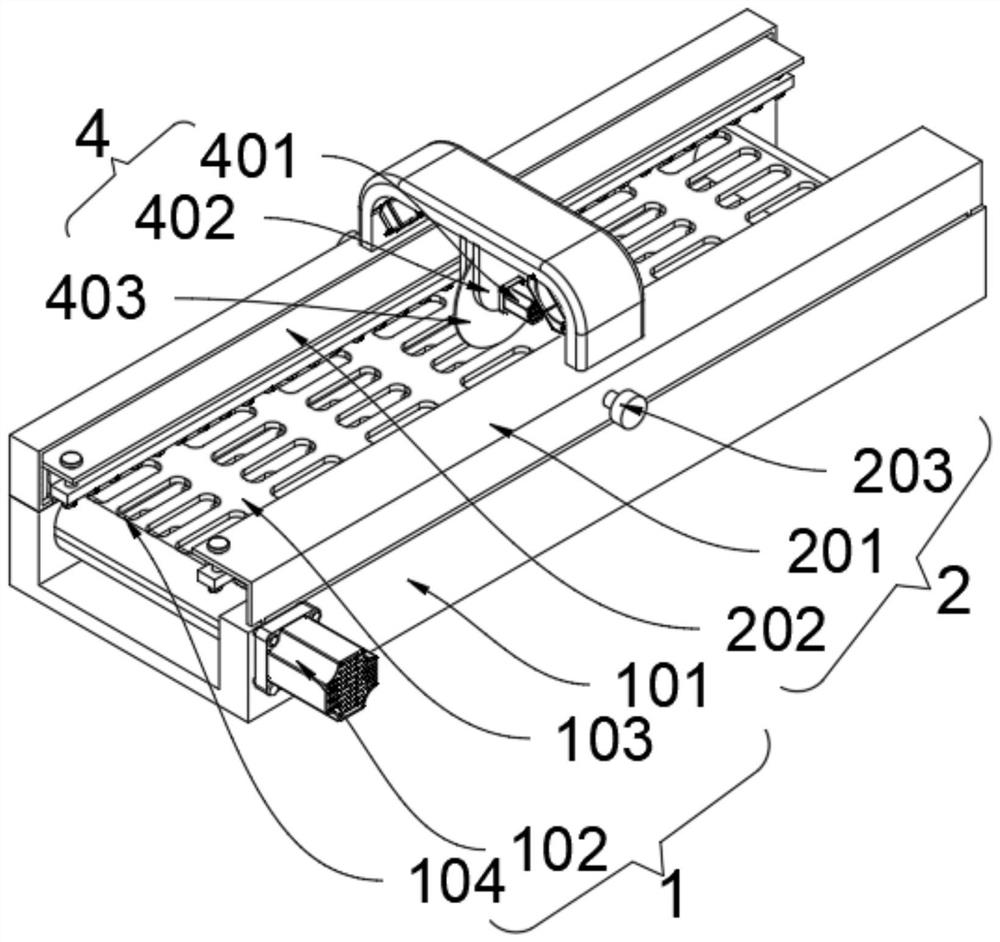

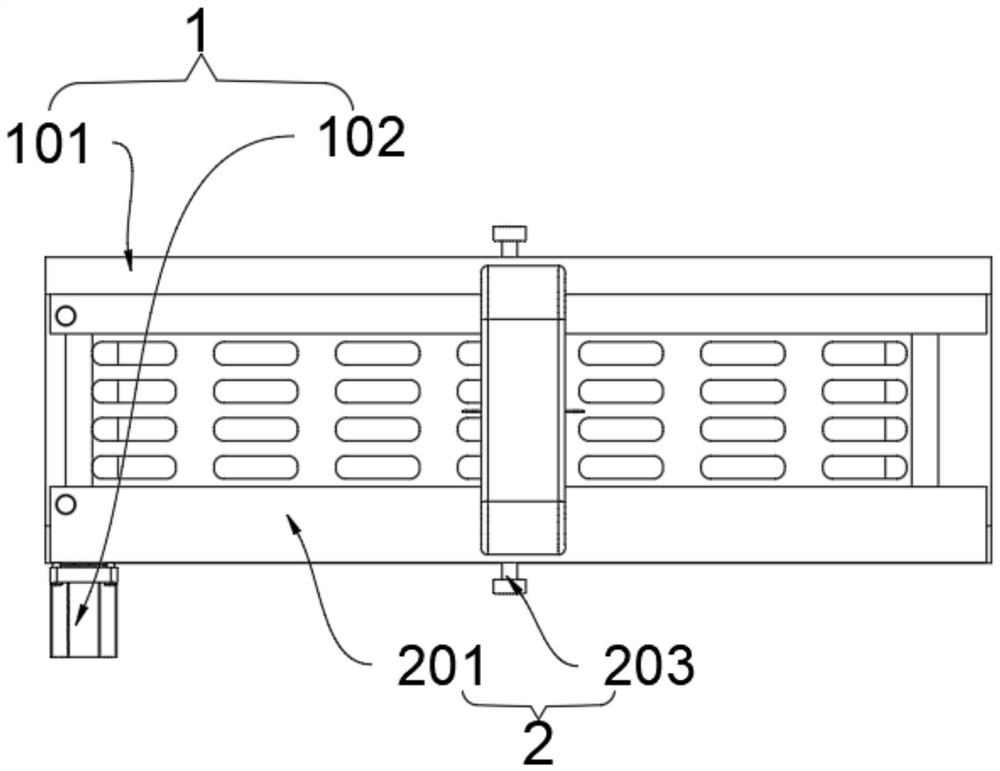

Swing type slitting knife device

The invention provides a novel thermal contraction film slitting device of a swing structure. The slitting device comprises a rolling shaft, constant speed rollers, positioning rollers, a power roller, a detection roller, a CCD sensor, an enabling roller, a rolling-out roller, an unrolling and deviation rectification execution mechanism and a swing device. The rolling shaft, the constant speed rollers, the positioning roller (4), the power roller, the detection roller, the CCD sensor, the enabling roller, the rolling-out roller and the unrolling and deviation rectification execution mechanism are connected in sequence; the swing device comprises a driving system, a sleeve, a breather pipe, a cutting knife arm, slitting knife blades, a cutting knife arm fixing track and a cylinder, the slitting knife blades are fixed on the cutting knife arm which moves on the cutting knife arm fixing track, one end of the cutting knife arm fixing track is in sliding contact with the driving system of the swing device, and the other end of the cutting knife arm fixing track is connected with the cylinder; the driving system comprises a frequency converter, the frequency converter controls a servo motor and is combined with an eccentric wheel through a driving shaft, and when the eccentric wheel rotates, the cutting knife arm fixing track (14) making contact with the eccentric wheel does reciprocating motion because of changes of the rotation radius; a thermal contraction film penetrates through the slitting knife blades and is slit between the positioning rollers.

Owner:河南银金达新材料股份有限公司

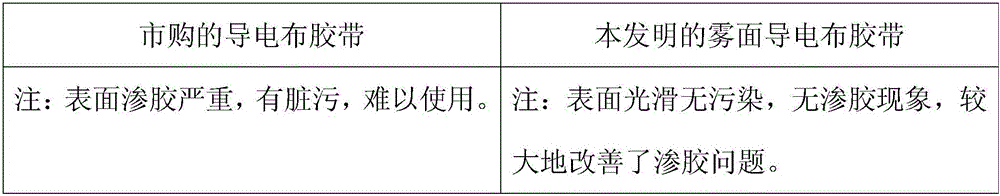

Non-bright, anti-fingerprint and scraping-resistant single-side adhesive tape for conductive fabric and preparation method

InactiveCN105754512AOptimize structureHigh toughnessNon-macromolecular adhesive additivesFilm/foil adhesivesPolyurethane adhesiveElectrically conductive

The invention discloses a non-bright, anti-fingerprint and scraping-resistant single-side adhesive tape for conductive fabric and a preparation method and belongs to the technical field of electromagnetic wave shielding. The conductive fabric material is subjected to special processing, a polyurethane adhesive film is applied to the surface of the conductive fabric material, and then an ink processing layer and a functional coating are applied. The original material structure is changed, the toughness of the material is enhanced, so that the tensile strength of the product is improved, and the surface has the anti-fingerprint, scraping-resistant and solvent-resistant functions. The working efficiency of a user can be increased, and the fraction defective of the product is reduced; the adhesive tape has good electrical properties, physical properties and market application prospect; besides, the preparation method is simple in process and easy to operate and facilitates industrial popularization and application.

Owner:江苏伊诺尔新材料科技有限公司

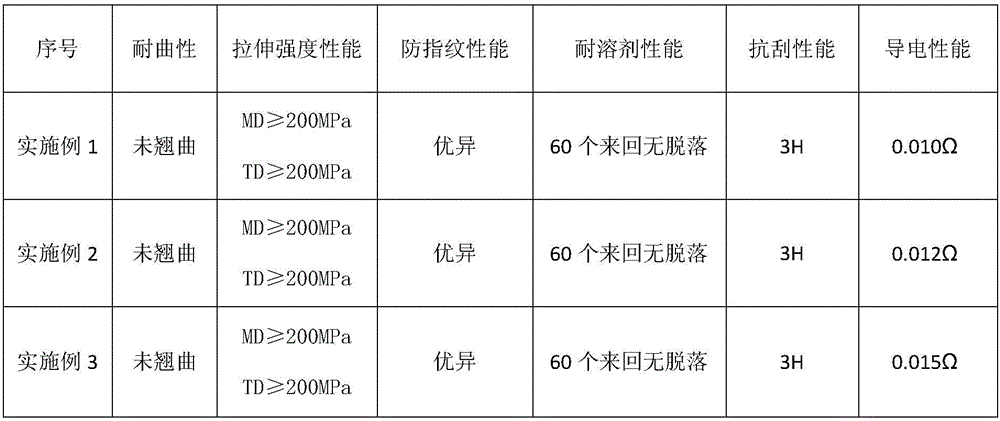

Predried non-film paperboard production equipment

InactiveCN106427068APrecise cuttingDo not interfereLiquid surface applicatorsMechanical working/deformationHigh energyPaperboard

The invention relates to predried non-film paperboard production equipment. The predried non-film paperboard production equipment comprises a corrugated paper pretreatment part, a facial tissue conveying part, cutting equipment and a positioning press-fit part; the corrugated paper pretreatment part is arranged at the front end of the facial tissue conveying part; the cutting equipment is arranged at the back end and the lower end of the facial paper conveying part; the positioning press-fit part is arranged at the back end of the cutting equipment; and the cutting equipment includes an upper synchronous cutter wheel and a lower synchronous support wheel. The predried non-film paperboard production equipment overcomes the problems of high energy consumption in production of corrugated paperboard, high pollution, unstable equipment operation, weak cutting effect and low paperboard strength.

Owner:CHANGXING SIAN MINFENG COLOR PRINTING FACTORY

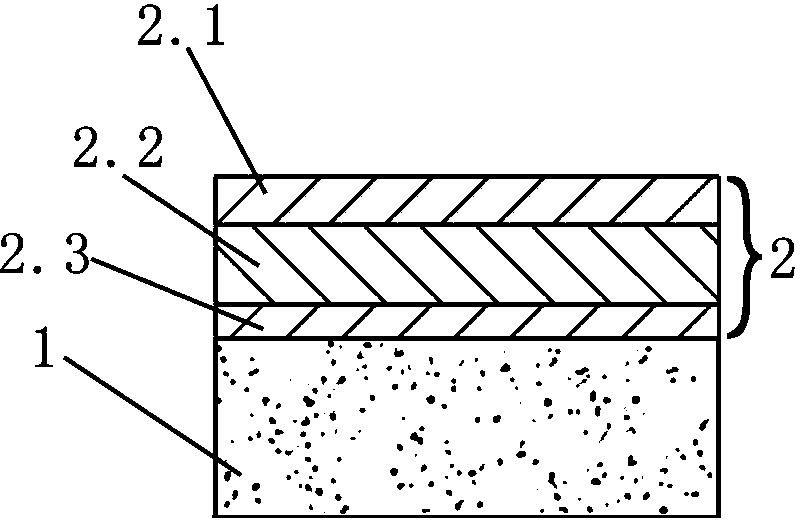

FDM (fused deposition modeling) 3 D (three dimensional) printing cold plate molding resin membrane

ActiveCN104015357AFlat surfaceNo edge warpingSynthetic resin layered productsCalcium carbonateHigh-density polyethylene

The invention discloses a FDM (fused deposition modeling) 3 D (three dimensional) printing cold plate molding resin membrane which has a thickness of 50-250mum, and comprises a hot melt layer, a base layer and a non-setting adhesive layer, the thickness ratio of hot melt layer to base layer to non-setting adhesive layer is 17-23:17-23:9-11; the hot melt layer is ethylene-vinyl acetate copolymer; the base layer contains high density polyethylene (75-85wt%), linear low density polyethylene (5-15wt%) and calcium carbonate (1-10wt%); the non-setting adhesive layer is an oily non-setting adhesive. The FDM (fused deposition modeling) 3 D (three dimensional) printing cold plate molding resin membrane has the advantages of low cost, when in use, a baseplate with a smooth and flat surface is required, and special requirements on the texture are not required. The problem of high cost of traditional 3D printing baseplates and adhesive films can be solved, and the problems of low safety and large machine loss caused by heating of the baseplates can be solved. In addition, the FDM (fused deposition modeling) 3 D (three dimensional) printing cold plate molding resin membrane is not only suitable for printing small-sized items, but also suitable for printing large-sized items (with the length, width and height up to 500mm), and edge warping problem may not be produced when in printing of the large-sized items.

Owner:HEBEI DAAI INTELLIGENT TECH CO LTD

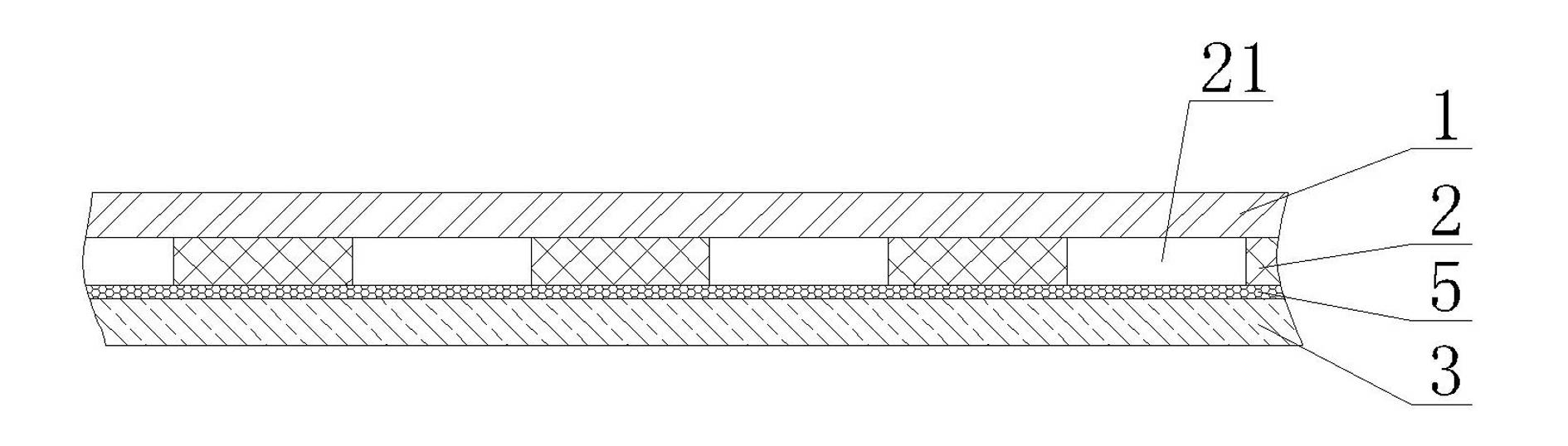

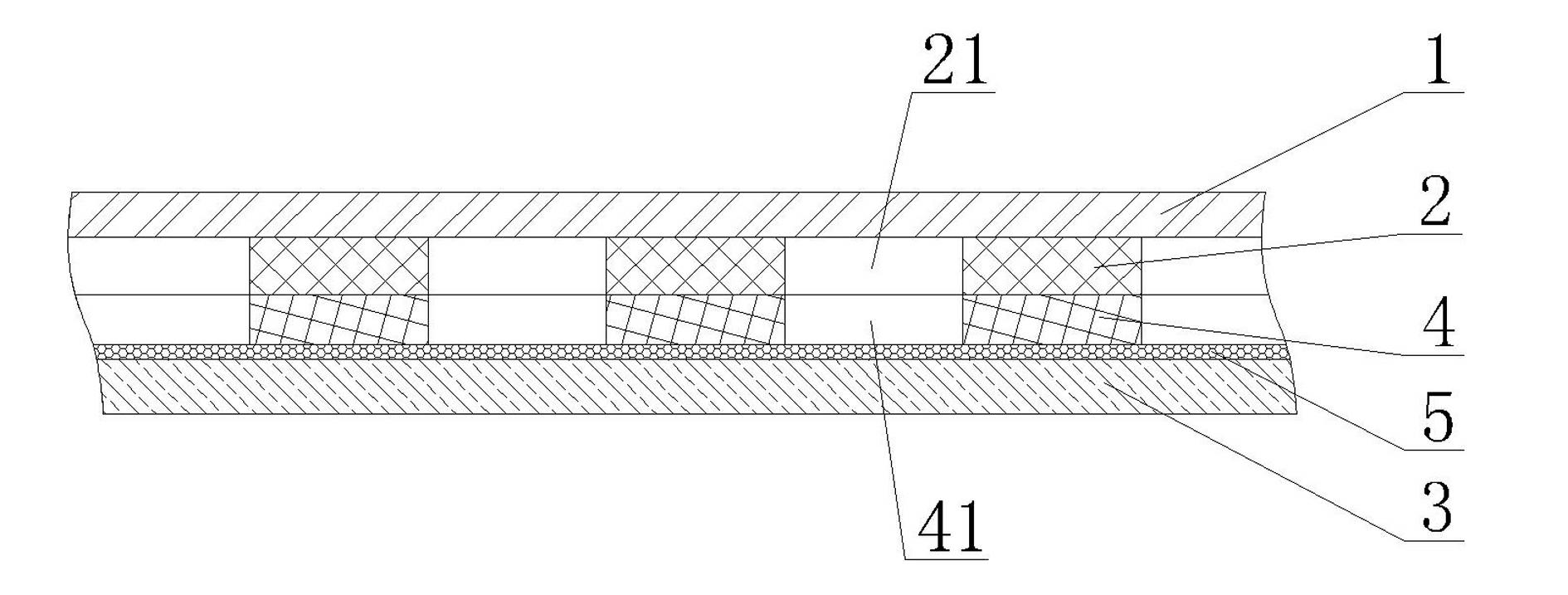

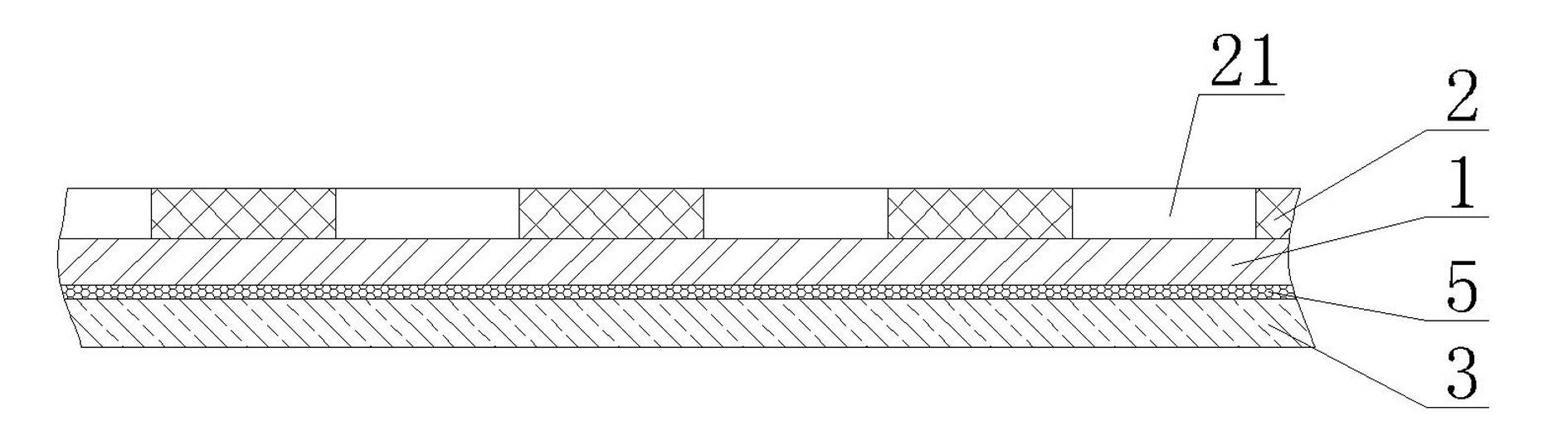

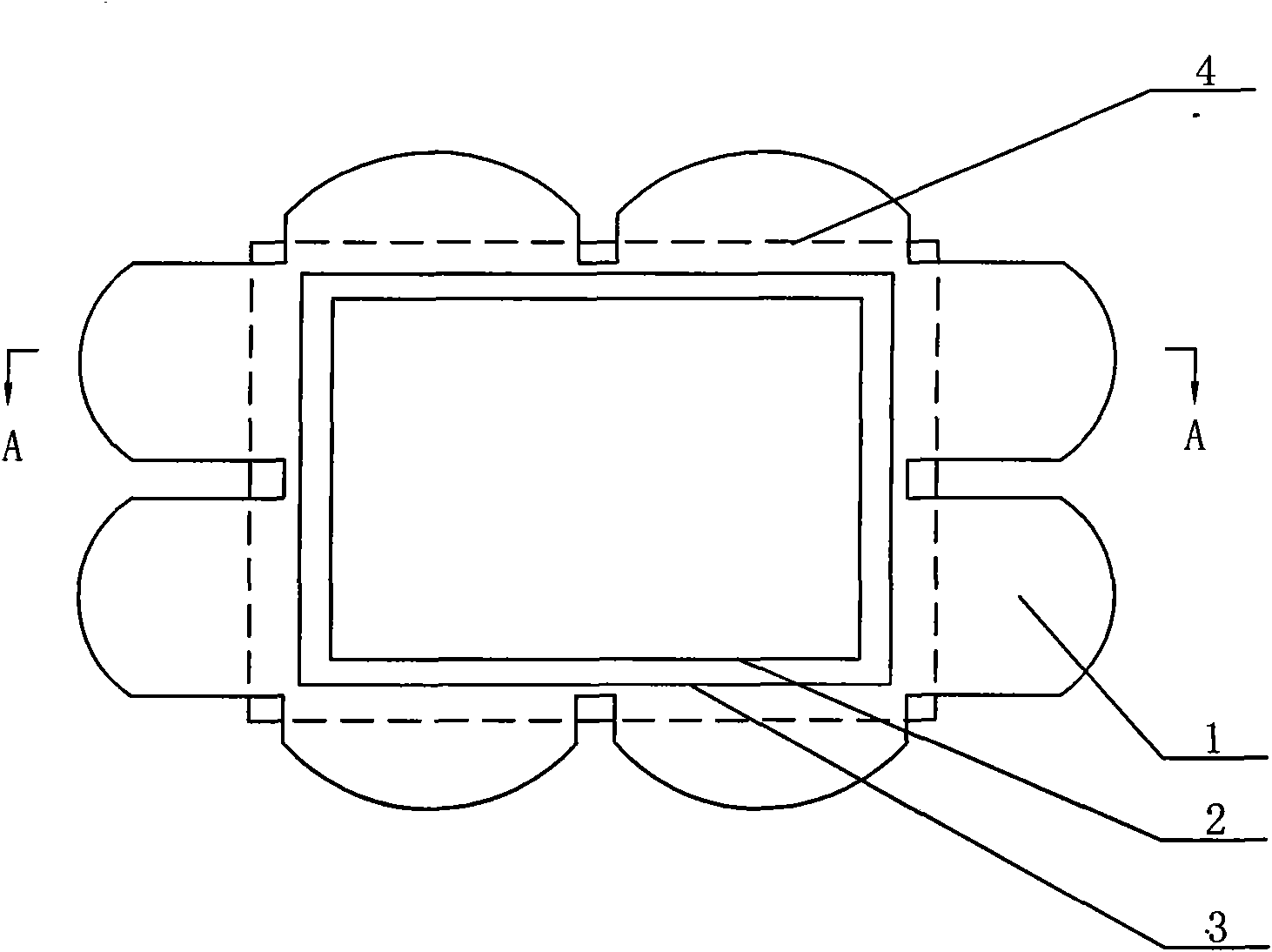

An externally-applied patch

InactiveCN101675920AFast absorptionPromote absorptionSkeletal disorderSheet deliveryThermostatPlastic film

An externally-applied patch relates to an externally-applied patch, which is composed of nonwoven (1), automatic thermostat heater (2), hydrogel transdermal ointment (3) and plastic film (4). The nonwoven (1) and the automatic thermostat heater are tightly connected, the hydrogel transdermal ointment is coated on the back line of the nonwoven, the automatic thermostat heater is arranged in the middle, and the surface of the hydrogel transdermal ointment (3) is covered with the plastic film. The present invention makes the hydrogel transdermal ointment enable to play medical action for a long time at a certain temperature by the continuous heating of the automatic thermostat heater, thereby reducing the effective time of the medicine, and improving the effect of medicine absorption; and thepresent invention has the advantages of convenient and comfortable use, large drug loading, strong penetrability, easy absorption, no residue, and no contaminated clothing.

Owner:倪海军

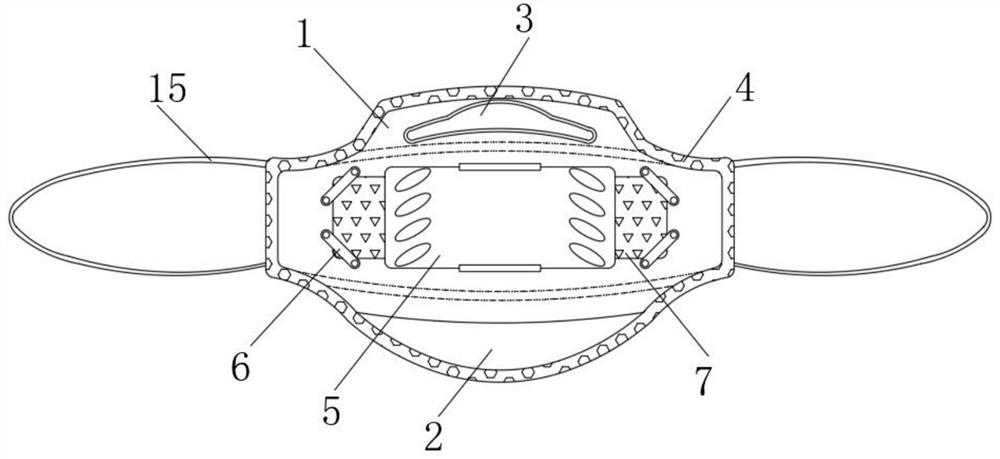

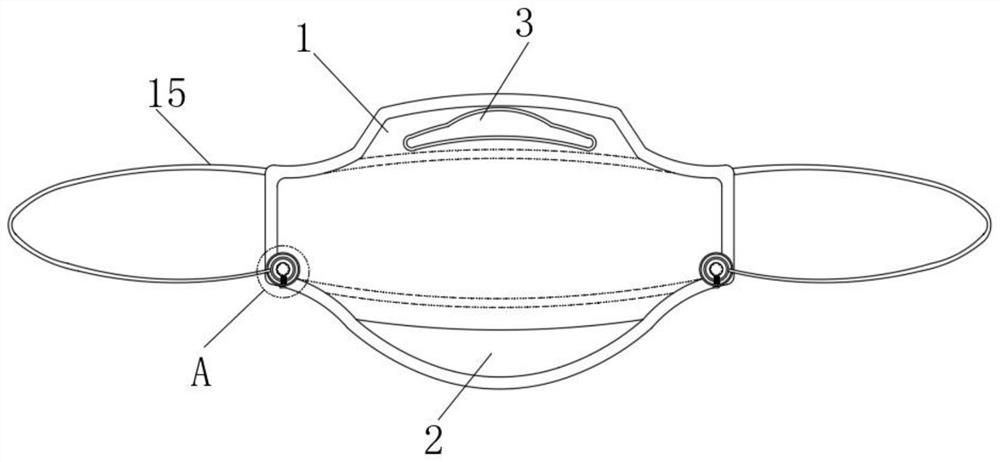

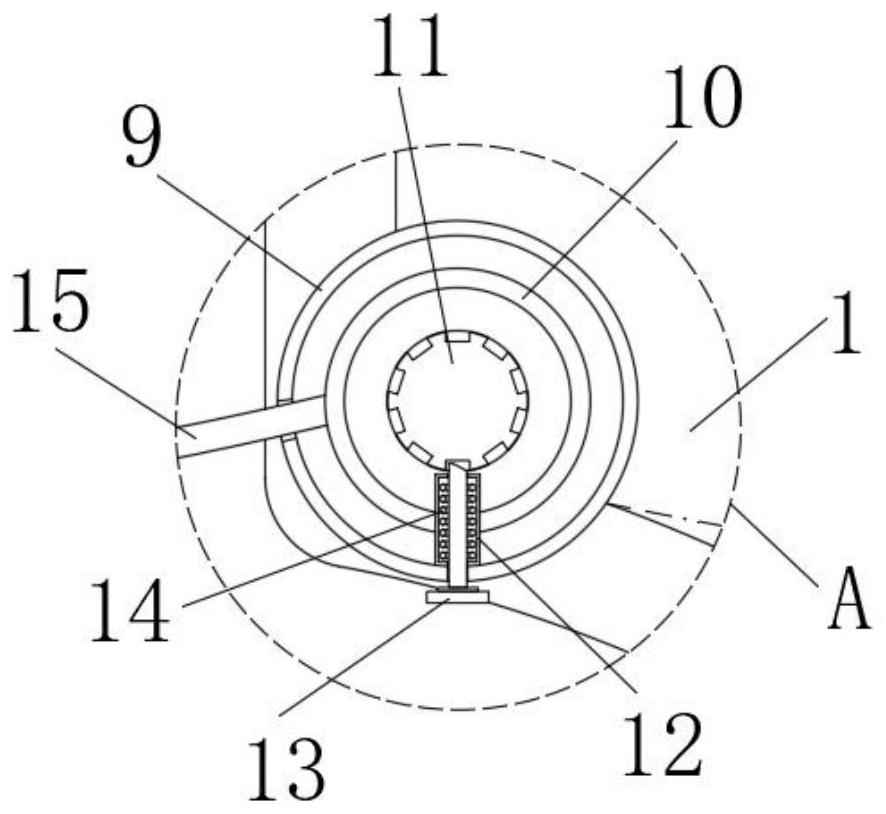

Novel mask with adjustable ear rope length

PendingCN111602889AAdjustable lengthEasy to replaceGarment special featuresGarment beltsEngineeringNonwoven fabric

The invention discloses a novel mask capable of adjusting the length of ear ropes. The mask comprises a mask body and a fixing block. A protective edge is sewn on the lower side of the mask body; a nose strip is arranged on the upper side of the mask body; limiting non-woven fabric is sewn in the mask body, a protective strip is sewn on the outer side of the limiting non-woven fabric; a filter element is installed in the limiting non-woven fabric, a pressing block is arranged on the back face of the mask body, a clamping block is arranged on the front face of the pressing block, the fixing block is fixedly connected to the front face of the clamping block, a coil is connected to the back face of the fixing block through a bearing, and a rotating block is fixedly connected to the front faceof the coil. By arranging a pull rod and a telescopic spring, a user can conveniently adjust the length of the ear ropes according to own requirements and can be well attached to the face of the user, and by arranging the limiting non-woven fabric and the protective strip, the filter element can be conveniently replaced, and the operation is easy.

Owner:河南华企丰源企业管理咨询有限公司

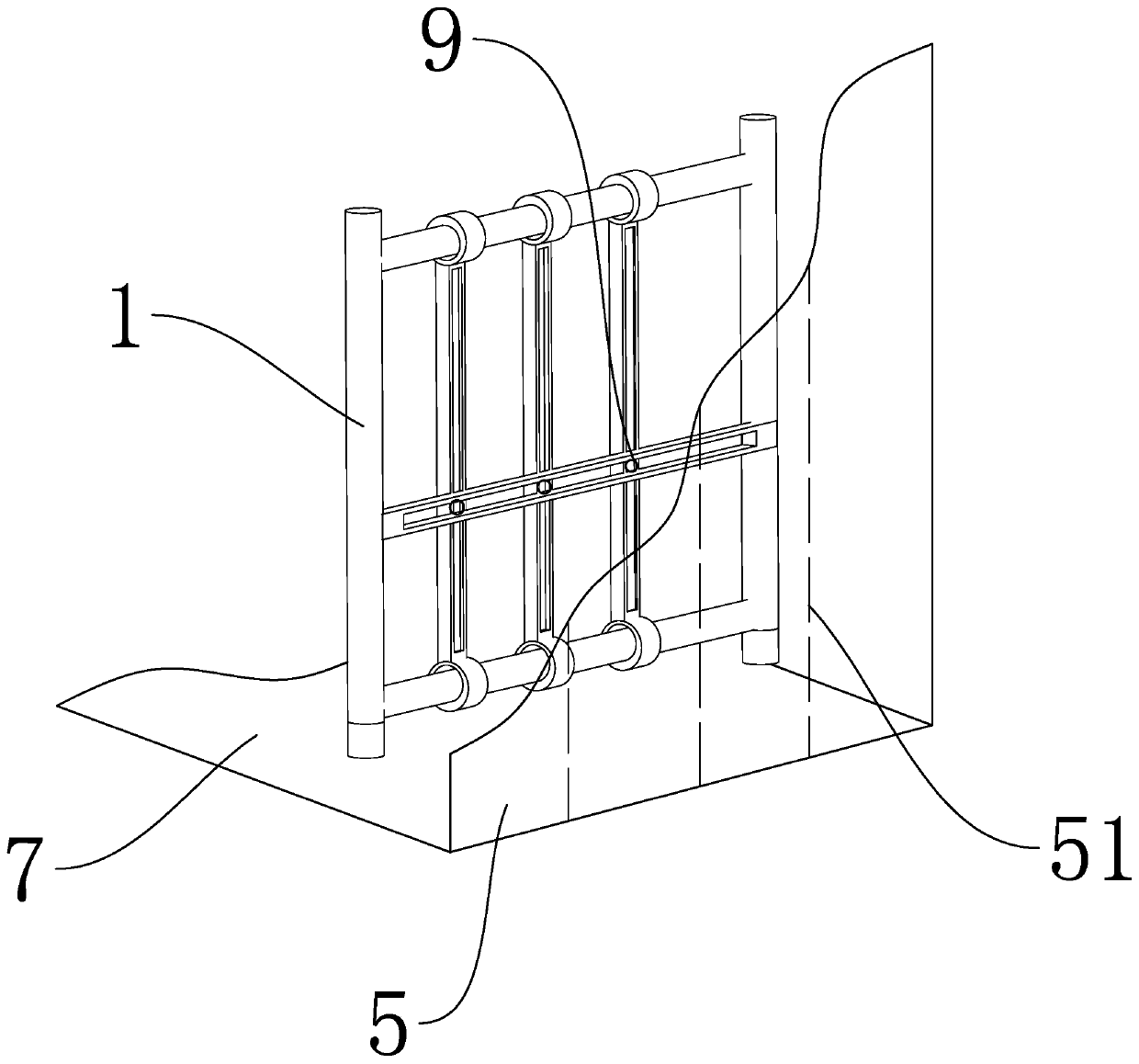

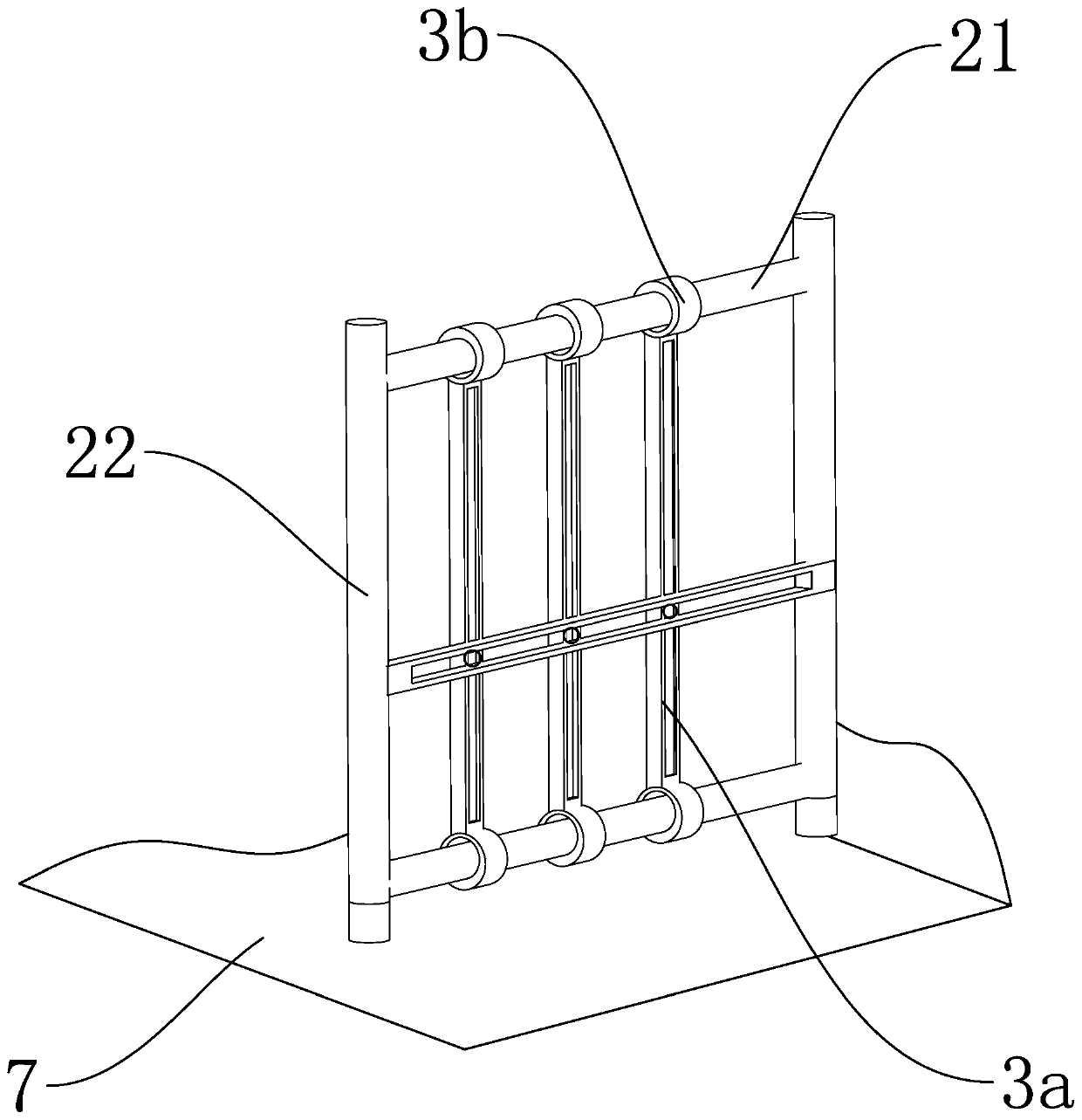

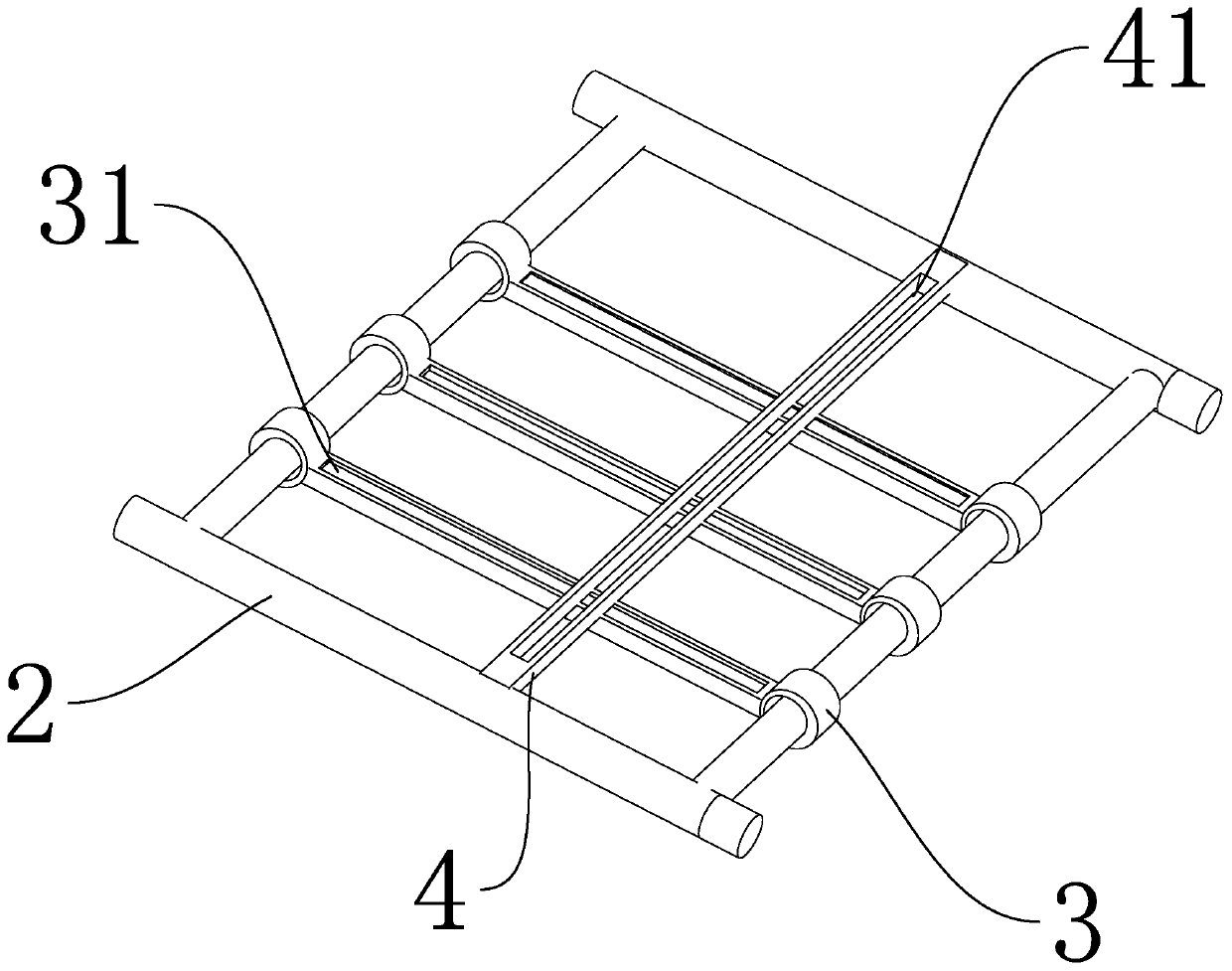

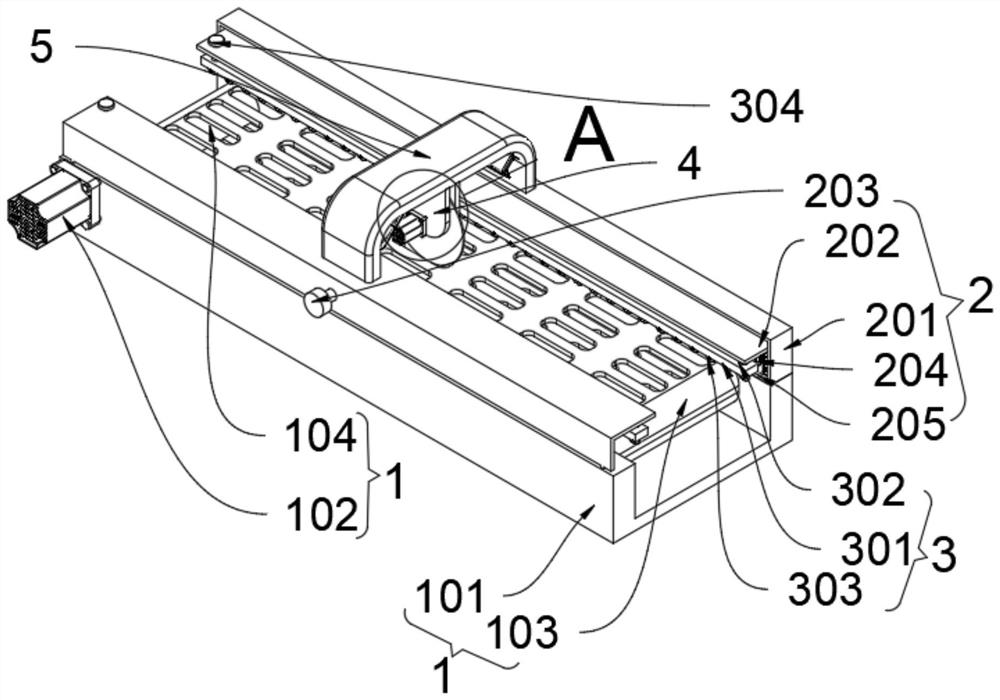

Adhesive scraping device for assisting in wallpaper mounting and adhesive scraping method

The invention discloses an adhesive scraping device for assisting in wallpaper mounting and an adhesive scraping method, and aims to solve the technical problems that in the prior art, a large amountof adhesive is stripped from a wall in an adhesive scraping process in the wallpaper mounting process, and edge warping is prone to occurring at a wallpaper joint after long-term use due to insufficient adhesive. The adhesive scraping device comprises a pre-arranging groove member and an adhesive scraping member. The pre-arranging groove member comprises a frame, a vertical sliding rod and a horizontal sliding rod; the two ends of the vertical sliding rod are separately movably sleeved with an upper connecting rod and a lower connecting rod of the frame; the upper connecting rod and the lowerconnecting rod are each provided with a limiting assembly for positioning the vertical sliding rod; the two ends of the horizontal sliding rod are separately movably sleeved with a left connecting rodand a right connecting rod of the frame; a vertical sliding groove is formed in the vertical sliding rod along the length direction of the vertical sliding rod; a horizontal sliding groove is formedin the horizontal sliding rod along the length direction of the horizontal sliding rod; and a groove forming part is movably connected at the intersection point of the vertical sliding groove and thehorizontal sliding groove. The adhesive scraping member comprises a scraping plate used for scraping and leveling a wallpaper splicing seam, and an adhesive storage opening is formed in a scraping blade, for leveling adhesive on wallpaper, of the scraping plate.

Owner:GREENTOWN DECORATION ENG GRP CO LTD

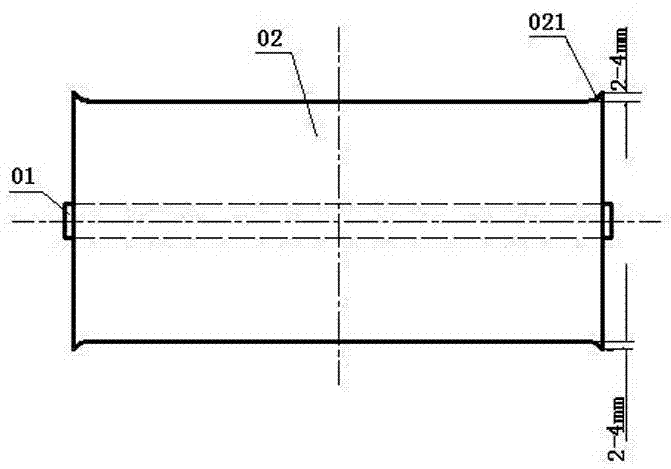

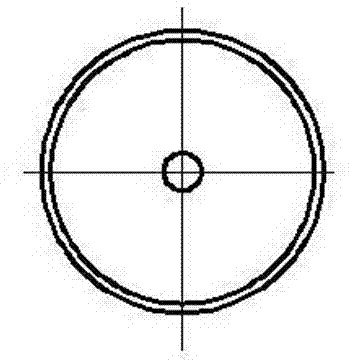

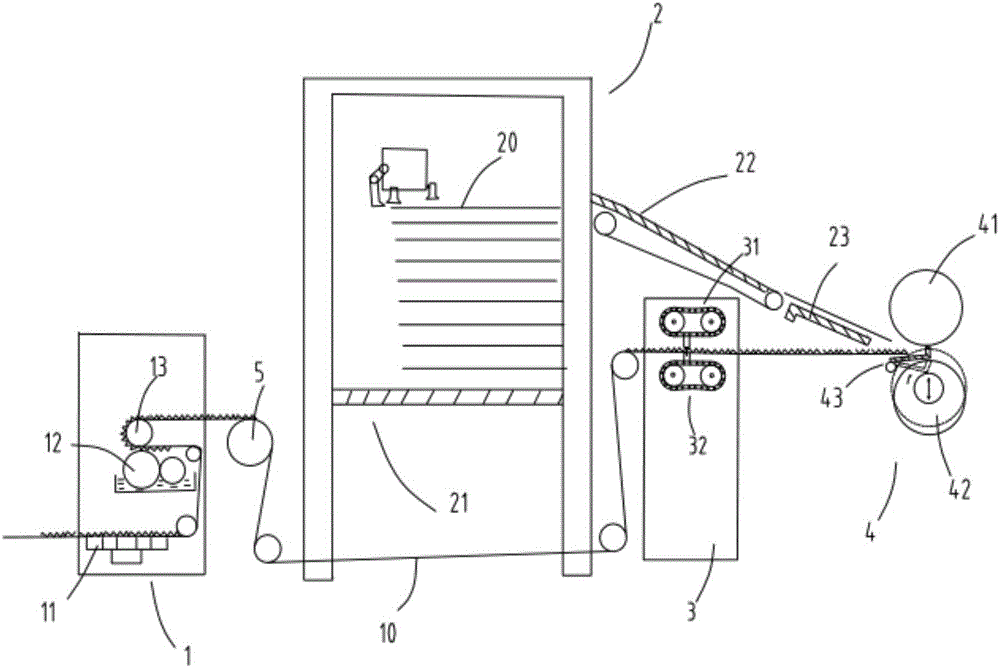

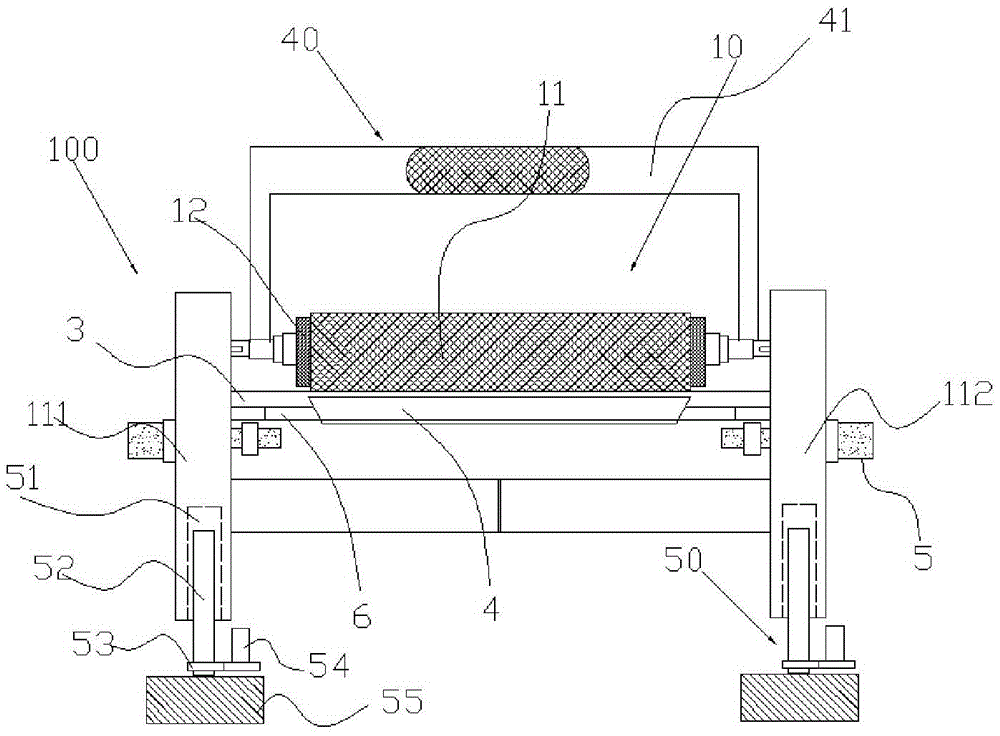

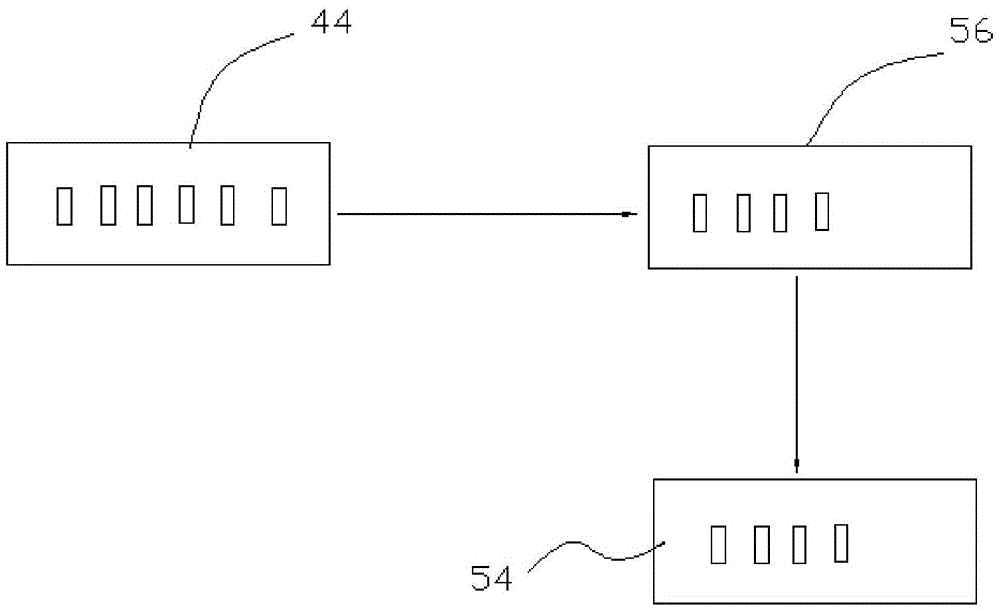

Circular screen printer device with antiskid roller

The invention discloses a circular screen printer device with an antiskid roller. The circular screen printer device comprises a circular screen and a printing conduction band and further comprises a long-strip-shaped trough arranged below the circular screen and the printing conduction band. Fixed frames are fixedly connected to the outer sides of the two ends of the long-strip-shaped trough in the longitudinal direction correspondingly. The fixed frames are fixed to a first vertical pillar and a second vertical pillar which are vertically arranged correspondingly. A roller printing device is fixed to the first vertical pillar and the second vertical pillar. The two ends of the roller printing device are rotationally connected with the first vertical pillar and the second vertical pillar correspondingly. The roller printing device is of a step type. The two ends of the roller are each provided with a small segment of step. The diameter of the middle area segment of the roller is larger than that of the area segments of the two ends of the roller. An antiskid structure used for increasing friction force is arranged on the part, located in the milled area segment, of the outer surface of the roller. The antiskid structure is antiskid lines formed on the outer surface of the roller printing device. The circular screen printer device is simple and reasonable in structure and ingenious in design concept.

Owner:SUZHOU HUACE TEXTILE SCI & TECH

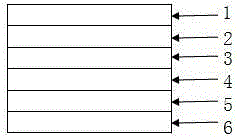

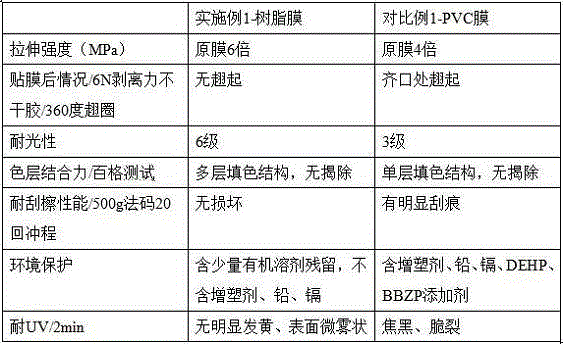

Green casting level automobile film and preparation method thereof

ActiveCN106553407AIncrease reflectionSteady fadeSynthetic resin layered productsLaminationPolyester resinReflective layer

The invention discloses a green casting level automobile film and a preparation method thereof. The film is successively provided with a color layer, a pressure-sensitive glue layer and release paper. A reflective layer is arranged between the color layer and the pressure-sensitive glue layer. The reflective layer is a white polyurethane layer or a white polyester resin layer. The green casting level automobile film mainly uses materials such as polyurethane and polyester resin, and the layers are combined through a coating process. The prepared casting level automobile film is good in elasticity. An edge warping phenomenon is unlikely to happen in a film pasting process, the construction efficiency is high and the yield is high. A protective layer is further arranged on the other side of the color layer of the casting level automobile film, so that the inner structure of the automobile film is protected well. The film can be of a capsule structure and can be made from a nanoscale material, so that the film is good in self-repairing property and high in self-cleanliness.

Owner:GUANGZHOU BAOLI TRADE

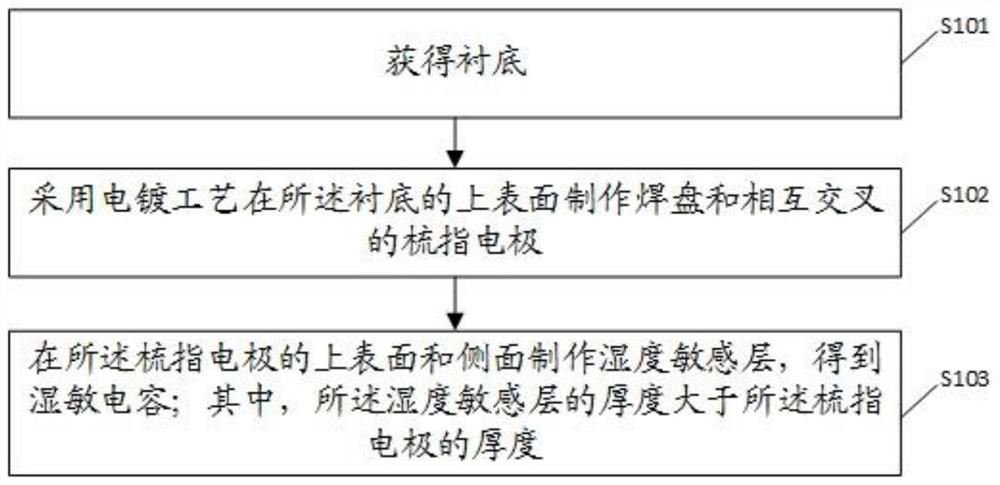

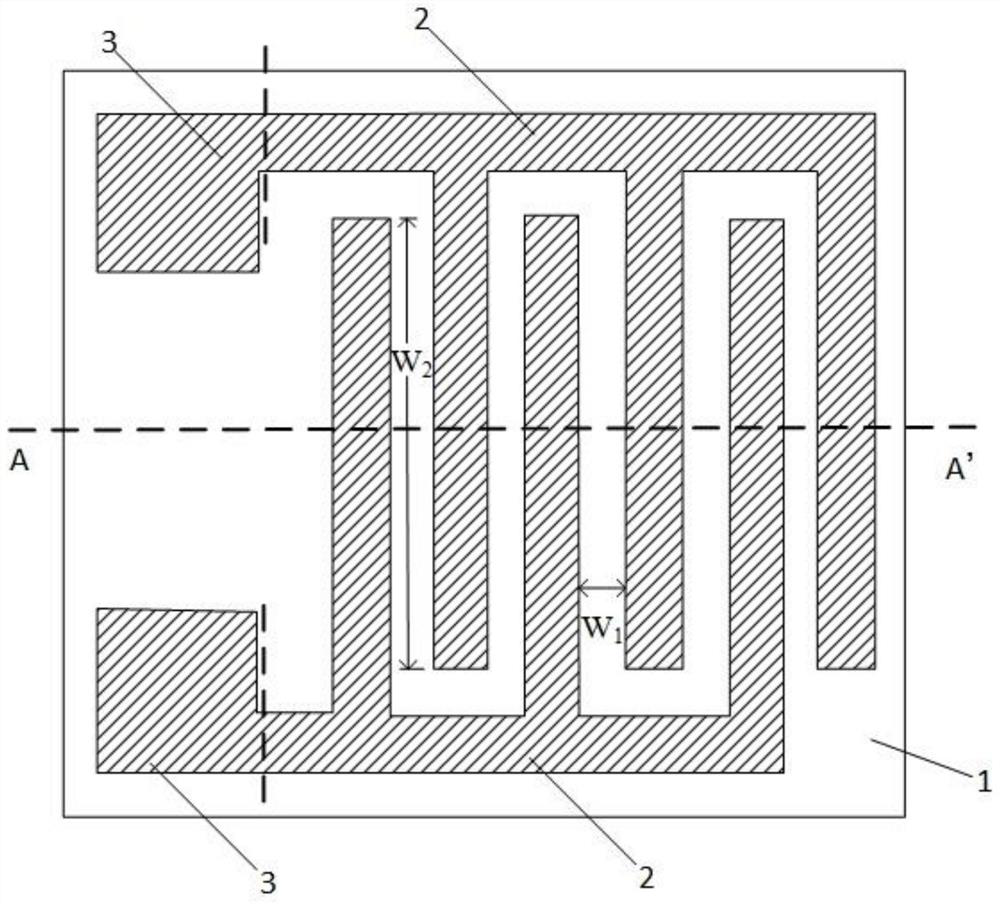

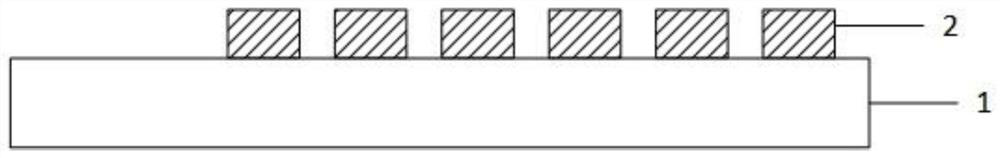

Humidity sensitive capacitor and manufacturing method thereof and humidity measuring equipment

PendingCN113380549AIncreasing the thicknessHigh sensitivityMaterial capacitanceNon-mechanically variable capacitorsHemt circuitsCapacitor

The invention discloses a humidity sensitive capacitor manufacturing method. The method comprises the steps of obtaining a substrate, manufacturing a bonding pad and mutually crossed comb finger electrodes on the upper surface of the substrate by adopting an electroplating process, and manufacturing humidity sensitive layers on the upper surface and the side face of the comb finger electrode to obtain a humidity sensitive capacitor, wherein the thickness of the humidity sensitive layer is greater than that of the comb finger electrode. According to the invention, the comb finger electrodes are manufactured in an electroplating mode, the electroplating process is a thick film metal process, the thickness of the comb finger electrodes can be larger than 1 micrometer, the thickness of the comb finger electrodes is increased, the opposite area between the crossed comb finger electrodes is increased so as to increase the basic capacitance and the capacitance variation of the humidity sensitive capacitor, improve the capacitance sensitivity and reduce the design difficulty of the humidity-sensitive capacitance detection circuit, and the manufacturing cost can be reduced through the electroplating mode. The invention further provides a humidity sensitive capacitor and humidity measuring equipment with the advantages.

Owner:NINGBO CRRC TIMES TRANSDUCER TECH CO LTD

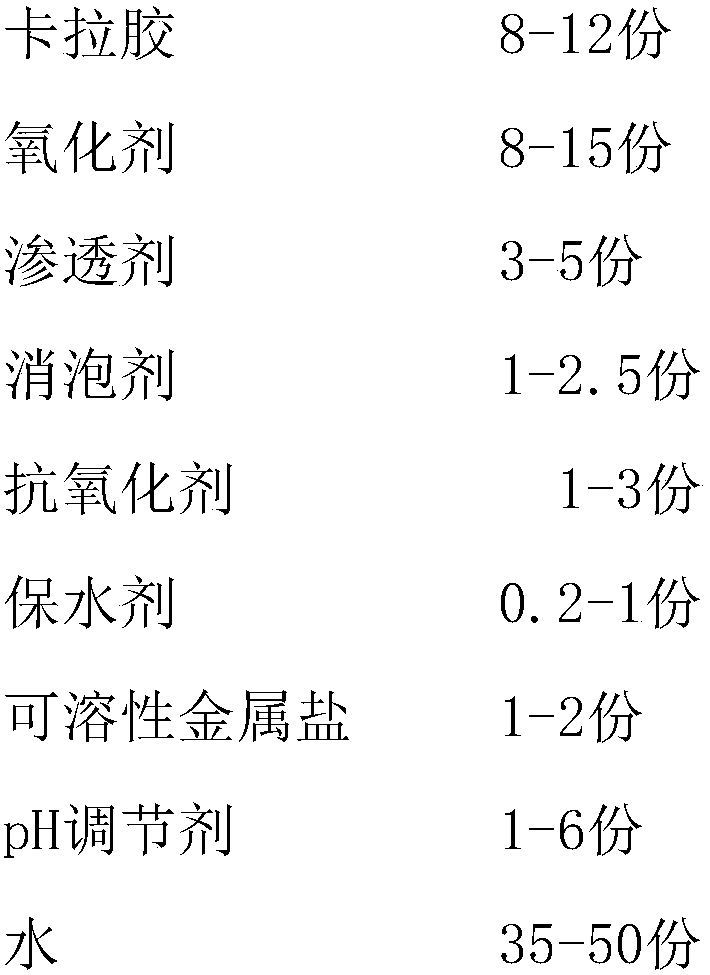

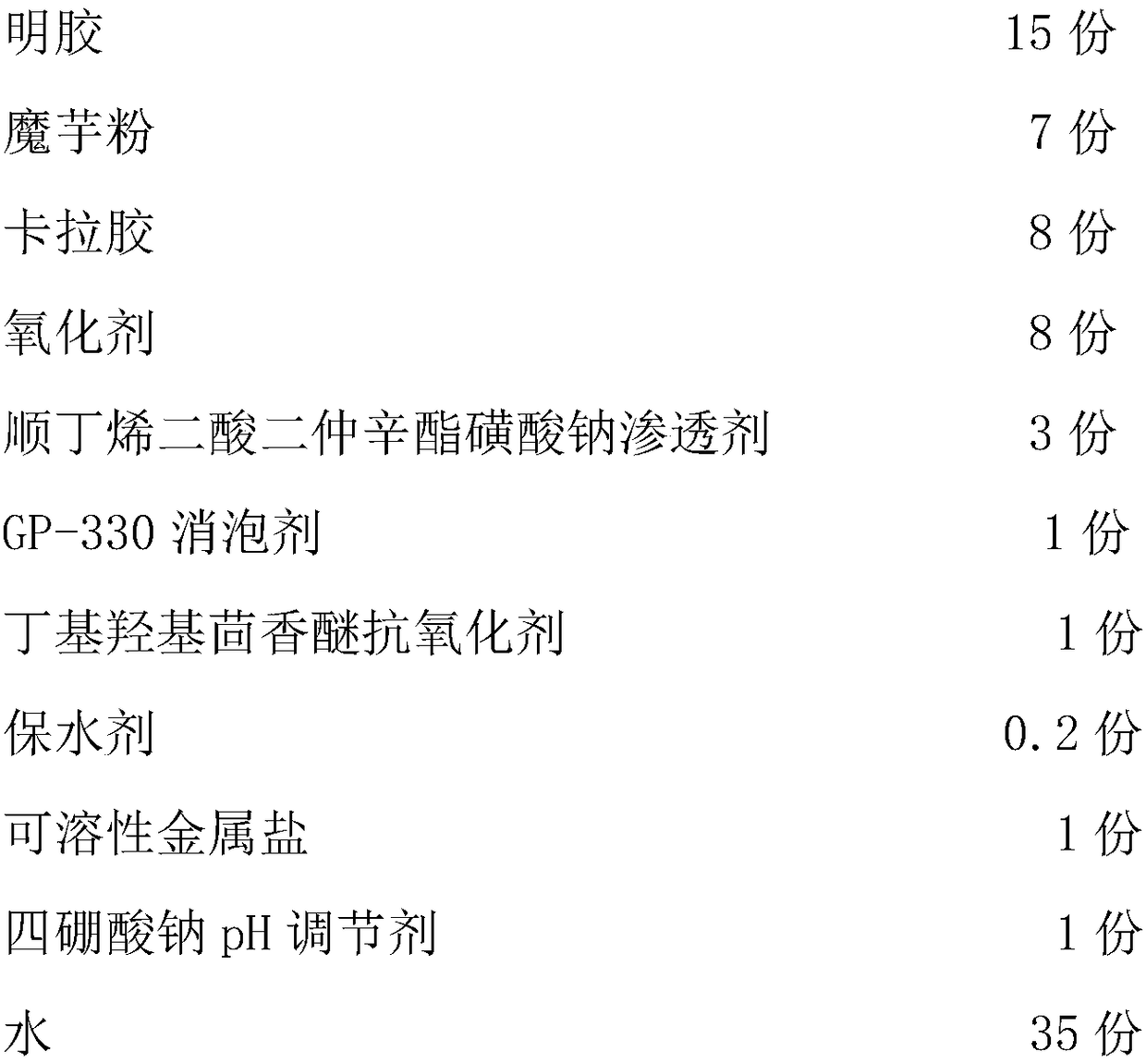

Environmentally friendly jelly glue and preparation method thereof

InactiveCN109439275AGood bonding performanceStable heat resistanceNon-macromolecular adhesive additivesProtein adhesivesDefoaming AgentsChemistry

The invention relates to the technical field of adhesives, in particular to environmentally friendly jelly glue and a preparation method thereof. The environmentally friendly jelly glue comprises thefollowing raw materials in parts by weight: 15-20 parts of gelatin, 7-15 parts of konjaku flour, 8-12 parts of carragheen, 8-15 parts of an oxidizing agent, 3-5 parts of a penetrating agent, 1-2.5 parts of a defoaming agent, 1-3 parts of an antioxidant, 0.2-1 part of a water-retaining agent, 1-2 parts of soluble metallic salt, 1-6 parts of a pH adjusting agent and 35-50 parts of water. The viscosity of the environmentally friendly jelly glue at the temperature of 60 DEG C is 900-1100 cps, a product produced by the environmentally friendly jelly glue can resist edge warping within 200-400 h inan environment at the temperature of 40-50 DEG C, and glue failure can be avoided within 200-350 h in an environment with the humidity of 90%-95%.

Owner:捷成实业(深圳)有限公司

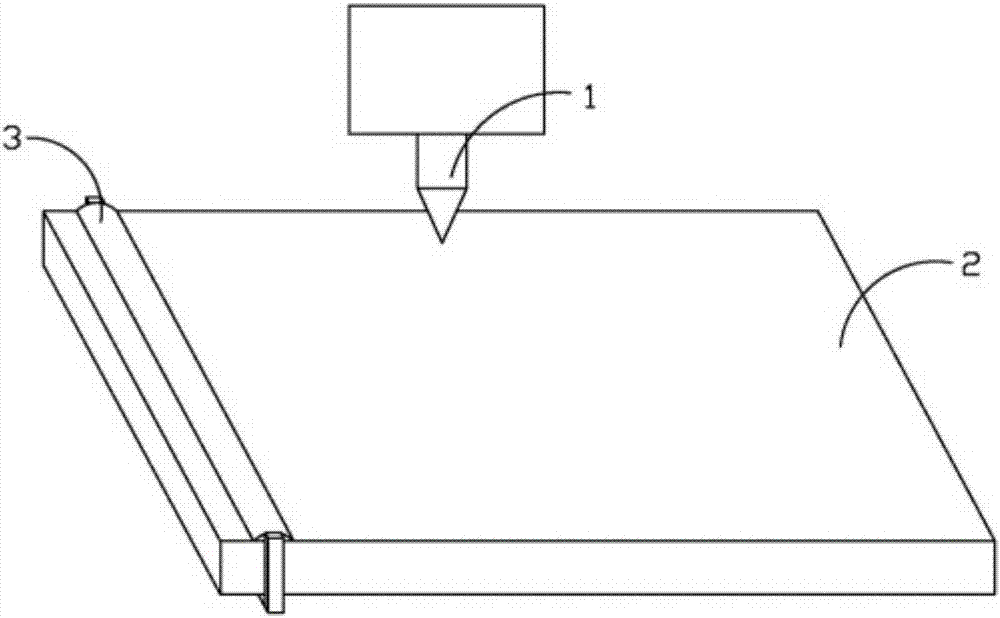

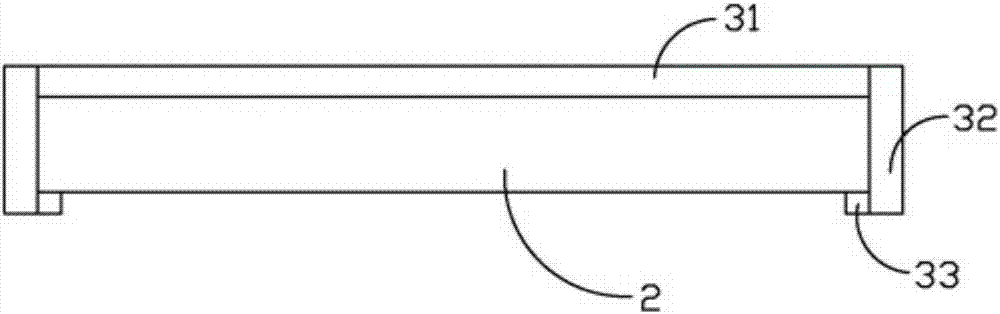

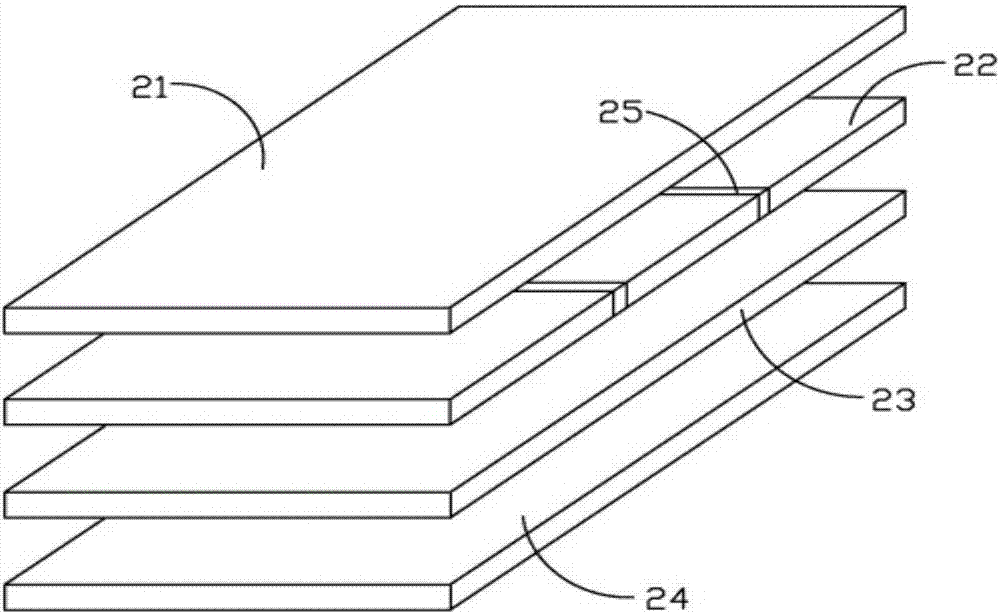

3D printer workbench

InactiveCN107443744AImprove removal efficiencySmall temperature fluctuationsManufacturing platforms/substratesManufacturing heating elementsThermal insulationControl switch

The invention provides a 3D printer workbench which comprises a printing platform under a 3D printer spray head and a cleaning mechanism for cleaning residues on the printing platform, wherein the cleaning mechanism and the printing platform are movably connected; the printing platform comprises a bottom plate, a thermal insulation layer, a constant temperature layer and a panel which are sequentially stacked from bottom to top; the constant temperature layer comprises a plurality of constant temperature plates which are arranged on the same horizontal plane in parallel and thermal insulation stripes arranged between every two thermal insulation plates, and each constant temperature plate is connected with a control unit which is used for controlling a temperature of the constant temperature plate. The workbench disclosed by the invention has a high residue cleaning efficiency and saves time and labor; a temperature of a contact face between a printed product and the panel is even to avoid the edge warping phenomenon, so that printing quality is improved; by controlling switches and temperatures of different constant temperature plates, energy waste caused by wholly heating the panel is avoided.

Owner:CHANGSHA YUANDAHUA INFORMATION TECH CO LTD

fdm 3D printing cold plate forming resin film

ActiveCN104015357BUnbreakableImprove tensile propertiesSynthetic resin layered productsLow-density polyethyleneLinear low-density polyethylene

The invention discloses a FDM (fused deposition modeling) 3 D (three dimensional) printing cold plate molding resin membrane which has a thickness of 50-250mum, and comprises a hot melt layer, a base layer and a non-setting adhesive layer, the thickness ratio of hot melt layer to base layer to non-setting adhesive layer is 17-23:17-23:9-11; the hot melt layer is ethylene-vinyl acetate copolymer; the base layer contains high density polyethylene (75-85wt%), linear low density polyethylene (5-15wt%) and calcium carbonate (1-10wt%); the non-setting adhesive layer is an oily non-setting adhesive. The FDM (fused deposition modeling) 3 D (three dimensional) printing cold plate molding resin membrane has the advantages of low cost, when in use, a baseplate with a smooth and flat surface is required, and special requirements on the texture are not required. The problem of high cost of traditional 3D printing baseplates and adhesive films can be solved, and the problems of low safety and large machine loss caused by heating of the baseplates can be solved. In addition, the FDM (fused deposition modeling) 3 D (three dimensional) printing cold plate molding resin membrane is not only suitable for printing small-sized items, but also suitable for printing large-sized items (with the length, width and height up to 500mm), and edge warping problem may not be produced when in printing of the large-sized items.

Owner:HEBEI DAAI INTELLIGENT TECH CO LTD

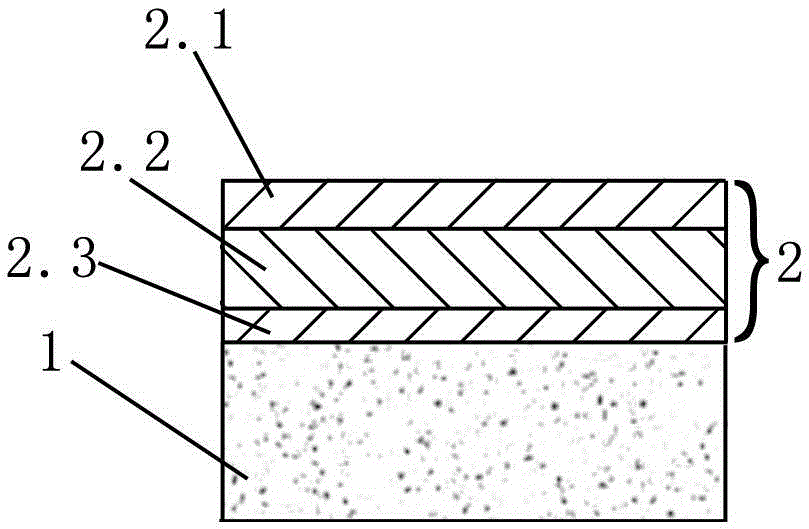

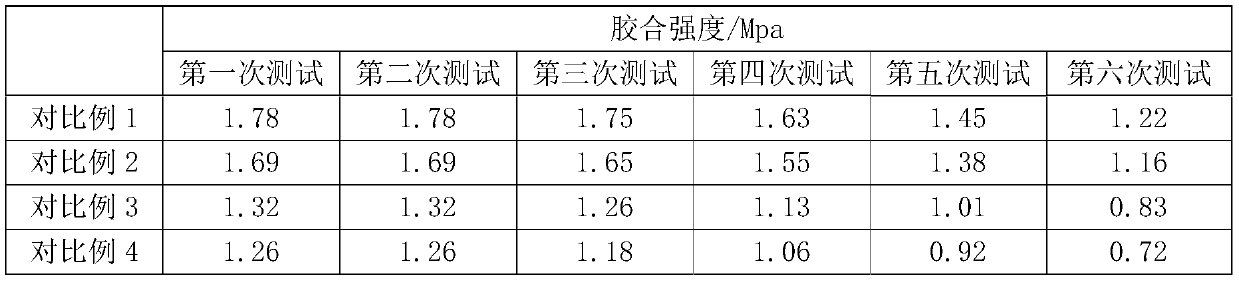

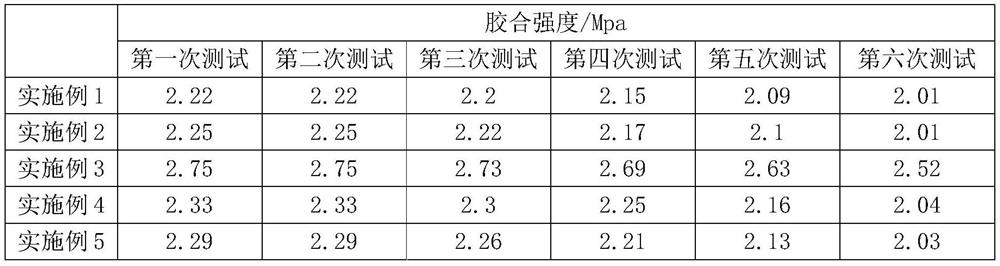

Preparation method of laminated board for wood floor

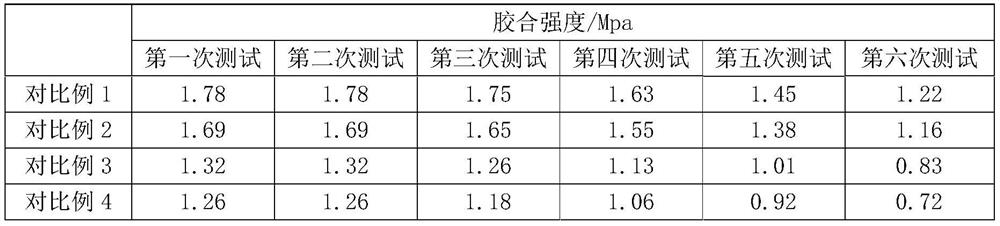

ActiveCN111086296AStrong Bond StrengthImprove bonding strengthMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesSurface finishingFirming agent

The invention discloses a preparation method of a laminated board for a wood floor. The preparation method comprises the following steps: (1) sorting a base board and a panel; (2) preparing an adhesive, wherein the adhesive is prepared from the following raw materials in parts by weight: 90-95 parts of urea-formaldehyde resin; 15-20 parts of polyvinyl acetate; 1-2 parts of a titanate coupling agent; 0.5-1 parts of chlorinated olefin; 0.1-0.5 parts of a retarding agent; 0.5-1 parts of a curing agent; 10-15 parts of a filling agent. The preparation method comprises the following steps: mixing and stirring the raw materials until the glue solution is pasty viscous liquid; (3) performing gluing; (4) performing veneering; (5) performing pressing; (6) performing trimming and edge sawing; and allowing the pressed wood board to be subjected to surface finishing, performing edge sawing according to the required specification to obtain the laminated board. The laminated board for the wood floorprepared through adoption of the method has high bonding strength, and it is guaranteed that the edge warping phenomenon does not occur in the using process.

Owner:广东柏高智能家居有限公司

A swing type cutting knife device

The invention provides a novel thermal contraction film slitting device of a swing structure. The slitting device comprises a rolling shaft, constant speed rollers, positioning rollers, a power roller, a detection roller, a CCD sensor, an enabling roller, a rolling-out roller, an unrolling and deviation rectification execution mechanism and a swing device. The rolling shaft, the constant speed rollers, the positioning roller (4), the power roller, the detection roller, the CCD sensor, the enabling roller, the rolling-out roller and the unrolling and deviation rectification execution mechanism are connected in sequence; the swing device comprises a driving system, a sleeve, a breather pipe, a cutting knife arm, slitting knife blades, a cutting knife arm fixing track and a cylinder, the slitting knife blades are fixed on the cutting knife arm which moves on the cutting knife arm fixing track, one end of the cutting knife arm fixing track is in sliding contact with the driving system of the swing device, and the other end of the cutting knife arm fixing track is connected with the cylinder; the driving system comprises a frequency converter, the frequency converter controls a servo motor and is combined with an eccentric wheel through a driving shaft, and when the eccentric wheel rotates, the cutting knife arm fixing track (14) making contact with the eccentric wheel does reciprocating motion because of changes of the rotation radius; a thermal contraction film penetrates through the slitting knife blades and is slit between the positioning rollers.

Owner:河南银金达新材料股份有限公司

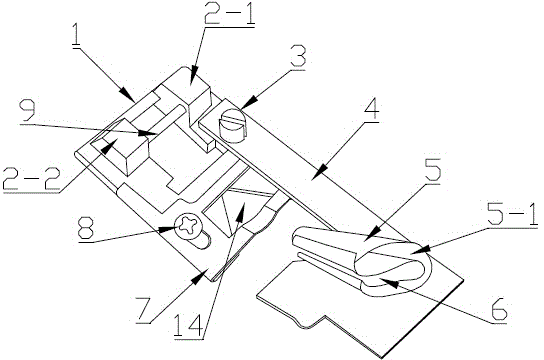

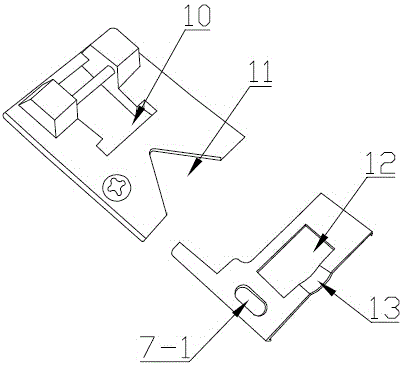

Braided fabric binding presser foot for sewing machine

The invention discloses a braided fabric binding presser foot for a sewing machine. The braided fabric binding presser foot comprises a presser foot bottom plate and a binding connecting plate. The front end of the presser foot bottom plate is provided with a triangular fork opening with which a slide piece is sleeved. A through hole is formed in the slide piece. The front end of the through hole is provided with a guide groove. The binding connecting plate is installed on the presser foot bottom plate through a first adjusting bolt. An edge curling plate is welded to the binding connecting plate. The two sides of the edge curling plate are bent towards the middle to form an edge curling groove. A guide plate is arranged in the edge curling groove. According to the braided fabric binding presser foot, binding of cloth and sewing of braided fabric and other decoration strips can be completed through one procedure; sewing lines are neat, no edge warping or edge omission occurs, and many processing steps are omitted.

Owner:嘉兴莱天华服饰有限公司

Environment-friendly processing equipment for thermal insulation ceramic tiles

InactiveCN114311336AEasy to processEfficient clamping operationWorking accessoriesBuilding constructionsThermal insulationDust control

The invention provides environment-friendly processing equipment for thermal insulation ceramic tiles, relates to the technical field of ceramic tile processing, and solves the problems that in the actual application process of existing ceramic tile processing equipment, dust generated during processing cannot be collected when ceramic tiles are cut; in order to solve the problems that a large amount of dust is generated during cutting, so that environmental pollution is caused by a large amount of dust generated during cutting, and in addition, ceramic tiles cannot be always guided in the forward direction in the cutting process, so that the ceramic tiles are damaged due to cutting deflection, the tile cutting device comprises two forward mechanisms, and the number of the forward mechanisms is two. A pressing plate and a pulley move downwards to efficiently clamp a ceramic tile through the pulley, the design can ensure that the situation that the edge of the ceramic tile is warped due to uneven stress when the ceramic tile is cut is avoided, and after the ceramic tile moves to the position under a support in a dust removal mechanism, a cutting blade is driven through a motor B; and therefore, efficient cutting operation can be conducted on the ceramic tiles.

Owner:董琳

Production process of PE (Poly Ethylene) protection film

PendingCN113980592AImproves UV resistanceImprove scratch resistanceFilm/foil adhesive release linersLow-density polyethyleneElastomer

The invention discloses a PE protection film production process, which comprises the following steps: S1, raw material preparation: preparing the following raw materials in parts by weight: 90 to 150 parts of low-density polyethylene, 2 to 5 parts of a thermoplastic elastomer, 8 to 18 parts of PE nano zinc oxide master batch, 0.8 to 1.6 parts of an ultraviolet absorbent, 0.8 to 1.6 parts of an UV antioxidant, 0.6 to 1.6 parts of an UV stabilizer, 10 to 24 parts of a dendritic toughening agent, 8 to 24 parts of an allyl elastomer, 10 to 20 parts of water-based acrylic acid and 30 to 60 parts of cross-linked polyacrylic acid; S2, base layer preparation; S3, adhesive preparation; S4, coating with an adhesive; S5, protection layer preparation; S6, coating with a protection layer: coating the surface of an adhesive on one side of a base layer with a protection layer by using a coating machine; S7, pressing and curing treatment; and S8, irradiation crosslinking modification treatment. According to the invention, a protection layer is laminated on the surface of a base layer through an adhesive, so that the ultraviolet resistance and the scratch resistance of the PE protection film are improved, and the PE protection film has relatively high dust and gravel impact resistance.

Owner:宿迁市日茂新材料有限公司

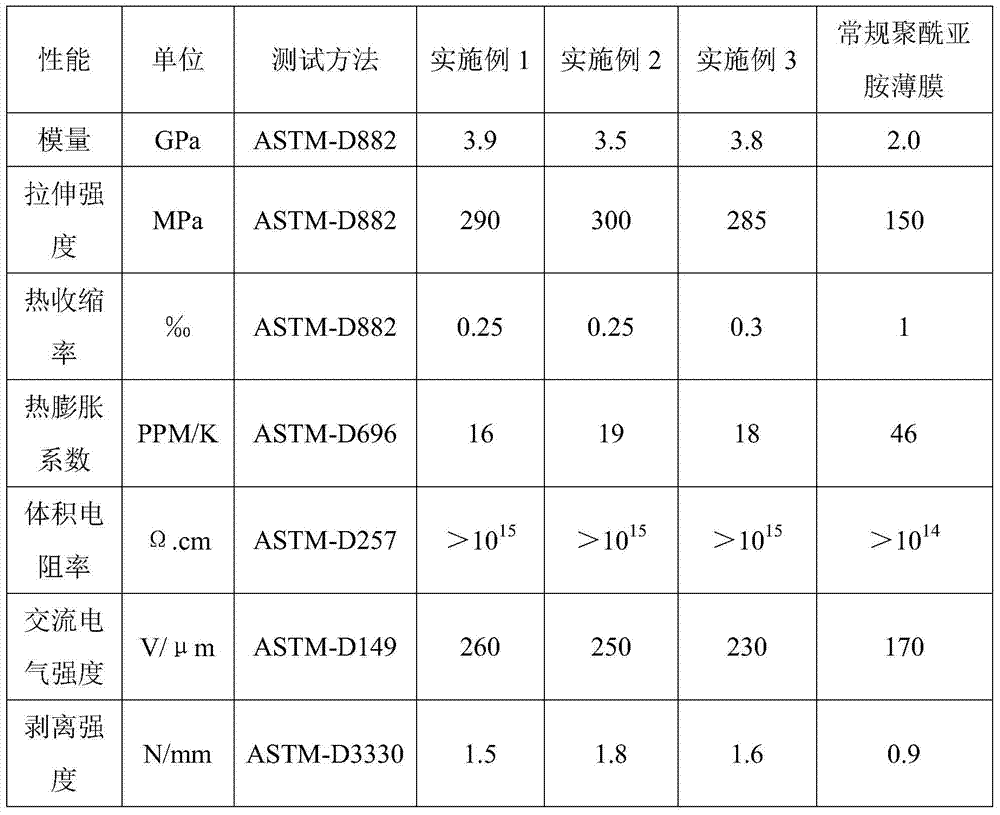

Preparation method of polyimide film with low thermal expansion coefficient

The preparation method of the low thermal expansion coefficient polyimide film of the present invention comprises the following steps: (1) placing pyromellitic dianhydride and p-phenylenediamine in a dimethylacetamide solvent for polycondensation reaction to obtain polyamic acid Glue A; (2) 2,3',3,4'-biphenyltetracarboxylic dianhydride and 4,4'-diaminodiphenyl ether were placed in dimethylacetamide solvent for polycondensation reaction to obtain poly Amic acid glue B; (3) polyamic acid glue A and polyamic acid glue B are mixed, and high-speed stirring reaction is obtained polyamic acid glue C; (4) polyamic acid solution C is made by casting process Form a film, and finally send the film into an imidization furnace for treatment to obtain the polyimide film with low thermal expansion coefficient. The CTE of the low thermal expansion coefficient polyimide film prepared by the invention is 15-17ppm / K, and it also has performance advantages such as high strength, high stability and high electric strength.

Owner:安徽统唯新材料科技股份有限公司

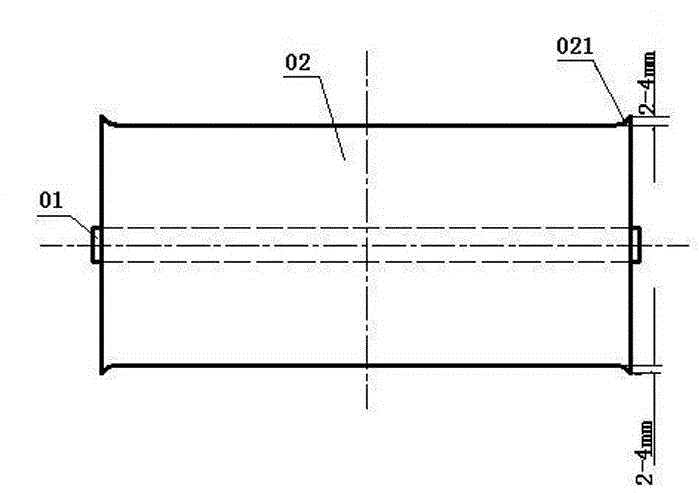

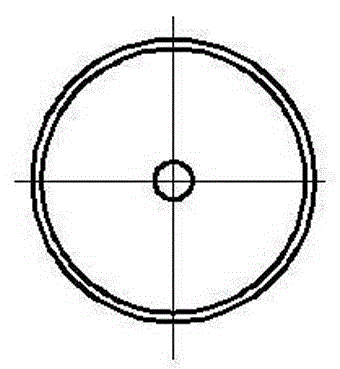

Perspective film

InactiveCN102371709AIncrease paste areaNo edge warpingLamination ancillary operationsLayered product treatmentEngineeringLight intensity

The invention discloses a perspective film, comprising a transparent film and backing paper, wherein a color-development printing layer is printed on the transparent film and is composed of color-development printing bodies and light transmitting areas, wherein the color-development printing bodies and the light transmitting areas are staggered; and the transparent film is laminated on the backing paper. According to the invention, because the color-development printing layer is directly printed on the transparent film, a pictured sprayed and drawn on the transparent is very clear by means of the color-development printing layer; in addition, because the color-development printing layer is composed of the staggered color-development printing bodies and light transmitting areas, the requirements of a light transmitting effect and a perspective effect can be met under the condition of guaranteeing the clear display of the sprayed picture; because the transparent film per se is not punched, the transparent film at the light transmitting areas can be used for blotter and coloring, the precision of the picture is high, the definition of the front face of the picture is greatly increased compared with that of the traditional unidirectional perspective patch, and the picture can be displayed from a back face and is not influenced by light intensity at two sides of a transparent plate; and the color-development printing layer is arranged on the transparent film in a printing manner, so that the production efficiency is greatly increased, the manufacture is more convenient and the production cost is low.

Owner:GUANGZHOU JIECHENG TECH CO LTD

A kind of preparation method of plywood for wooden floor

ActiveCN111086296BHigh bonding strengthNo edge warpingMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesAdhesive cementPolyvinyl acetate

The invention discloses a preparation method of a veneer for wood flooring, which comprises the following steps: (1) sorting the substrate and the panel; (2) configuring an adhesive: the adhesive includes the following raw materials in parts by weight: urea-formaldehyde resin: 90-95 parts; polyvinyl acetate: 15-20 parts; titanate coupling agent: 1-2 parts; chlorinated olefins: 0.5-1 parts; retarder: 0.1-0.5 parts; curing agent: 0.5-1 parts; Agent: 10-15 parts; mix and stir the above raw materials until the glue is a paste-like viscous liquid, and it is obtained; (3) glue coating; (4) veneer; (5) pressing; (6) trimming and sawing; Surface finishing of the pressed planks and edge sawing to the required specifications, vested. The wood floor veneer prepared by the method has strong bonding strength, which ensures that no edge warping occurs during use.

Owner:广东柏高智能家居有限公司

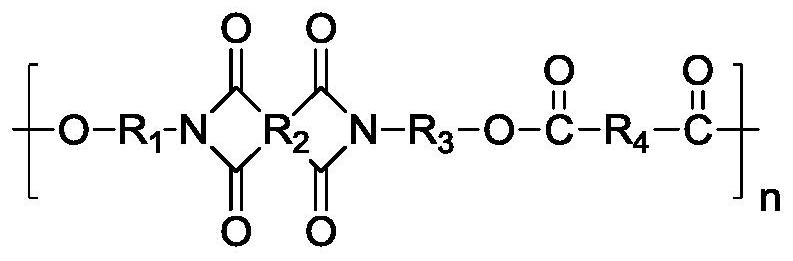

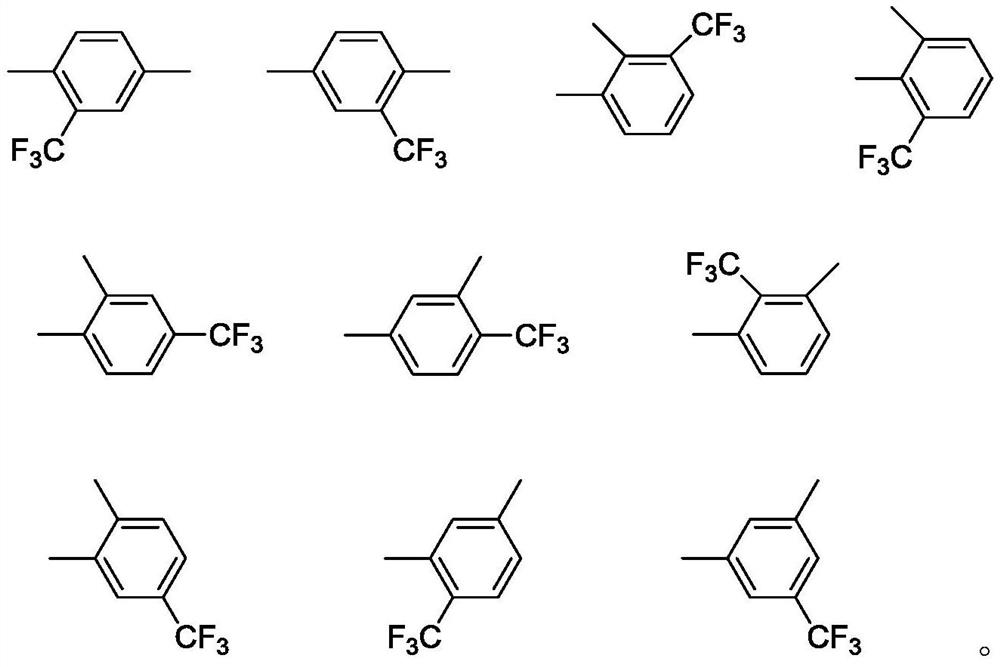

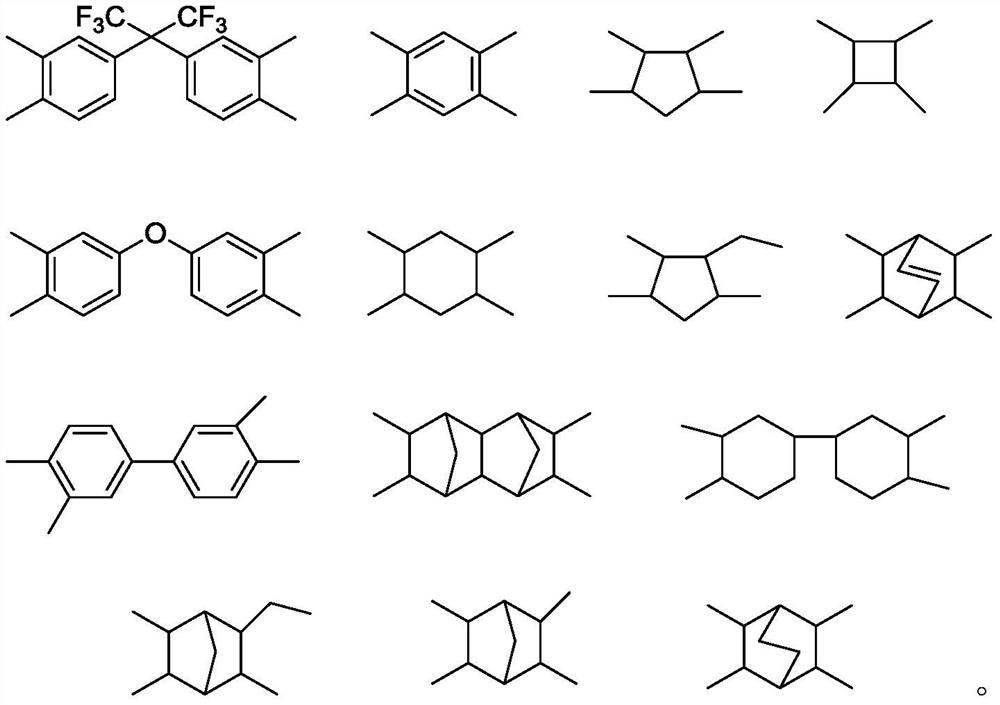

A kind of polyimide film with low thermal expansion coefficient and preparation method thereof

ActiveCN111592758BSmall coefficient of thermal expansionGood flexibilityThermal dilatationPolymer science

The invention proposes a polyimide film with low thermal expansion coefficient and a preparation method thereof. By introducing structural units such as ester bonds into the molecular structure, the polyimide film with low thermal expansion coefficient and high mechanical performance is obtained.

Owner:ZHEJIANG OCAS NEW MATERIALS CO LTD

A kind of green foundry grade car film and preparation method thereof

ActiveCN106553407BIncrease reflectionSteady fadeSynthetic resin layered productsLaminationPolyester resinReflective layer

The invention discloses a green casting level automobile film and a preparation method thereof. The film is successively provided with a color layer, a pressure-sensitive glue layer and release paper. A reflective layer is arranged between the color layer and the pressure-sensitive glue layer. The reflective layer is a white polyurethane layer or a white polyester resin layer. The green casting level automobile film mainly uses materials such as polyurethane and polyester resin, and the layers are combined through a coating process. The prepared casting level automobile film is good in elasticity. An edge warping phenomenon is unlikely to happen in a film pasting process, the construction efficiency is high and the yield is high. A protective layer is further arranged on the other side of the color layer of the casting level automobile film, so that the inner structure of the automobile film is protected well. The film can be of a capsule structure and can be made from a nanoscale material, so that the film is good in self-repairing property and high in self-cleanliness.

Owner:GUANGZHOU BAOLI TRADE

Method for preventing overflow of hot melt adhesive

The invention provides a method for preventing overflow of a hot melt adhesive. The method comprises the following specific steps: (1) carrying out heating hot melting on hot melt adhesive to melt the adhesive; (2) controlling the temperature of the hot melt adhesive to be constant by using a temperature controller, coating molten hot melt adhesive to a to-be-pasted label, wherein a blank edge of 0.3-0.7mm is reserved at the edge of the label; and (3) operating a labeling machine to complete a labeling procedure. According to the method, due to specific edge reserving distance and selection of the hot melt adhesive, the phenomenon of edge warping can be avoided while realizing zero overflow of the adhesive during an operation, and therefore, the method is suitable for meeting the requirements of large-scale industrial production.

Owner:天津市西祥塑料制品有限公司

Preparation method of polyimide film

ActiveCN105111476BMulti-flex keySmall coefficient of thermal expansionComposite filmDiaminodiphenyl ether

The preparation method of the polyimide film of the present invention comprises the following steps: (1) placing pyromellitic dianhydride and 4,4'-diaminodiphenyl ether in a dimethylacetamide solvent for polymerization reaction to obtain Polyamic acid glue A; (2) 3,3',4,4'-benzophenone tetracarboxylic dianhydride and p-phenylenediamine are placed in dimethylacetamide solvent for polymerization reaction to obtain polyamide Acid glue B; (3) mixing polyamic acid glue A and polyamic acid glue B; (4) preparing nano-montmorillonite ultrafine powder dispersion; (5) mixing nano-montmorillonite ultrafine powder The body dispersion is fully dispersed in the multi-component polyamic acid glue to obtain the polyamic acid composite glue; (6) the polyamic acid composite glue is made into a film through the salivation molding process, and finally the film is sent into the imidization furnace After processing, the polyimide film is obtained. The polyimide film prepared by the invention has performance advantages such as low coefficient of thermal expansion, high strength, high stability and high electric strength.

Owner:安徽统唯新材料科技股份有限公司

Waterborne PP (polypropylene) straight surface sticker and manufacturing process thereof

InactiveCN110055004AImprove performanceCompact structureFilm/foil adhesive primer layersCoatingsPolypropyleneViscosity

The invention discloses a waterborne PP straight surface sticker and a manufacturing process thereof. The waterborne PP straight surface sticker is composed of a base material, a coating, glue, a bottom layer and a release paper, wherein the coating is uniformly applied onto the lower surface of the base material, one surface of the bottom layer is adhered to one surface of the coating, the othersurface of the bottom layer is coated with the glue to form a glue layer, and the release paper is adhered to the glue layer. By improving the formula and the manufacturing method of the straight surface sticker, the properties of the straight surface sticker can be improved, the manufactured straight surface sticker can be structurally compact among layers and less prone to loosening and deformation during application, meanwhile, the glue layer is high in viscosity and less prone to falling off during application, so that the waterborne PP straight surface sticker has a broad market space.

Owner:中山市旭森涂层材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com