Green casting level automobile film and preparation method thereof

A car film and green technology, applied in the field of green casting grade car film and its preparation, can solve the problems of increased rigidity of the finished car film, brittle protective film, stress retraction, etc., to improve the scratch resistance and reduce the surface Tension, the effect of simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

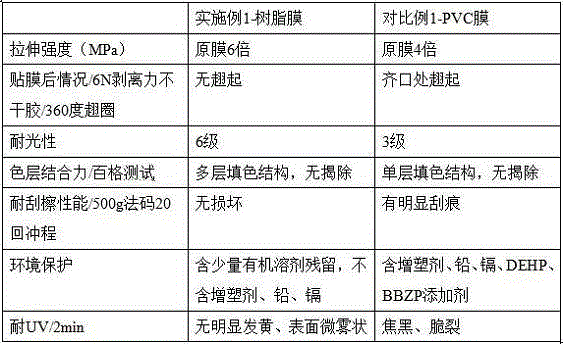

Embodiment 1

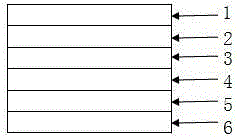

[0028] as shown in the picture 1 It is a green cast-grade car film, which is sequentially provided with a color layer 3 , a pressure-sensitive adhesive layer 5 and a release paper 6 , and a reflective layer 4 is arranged between the color layer 3 and the pressure-sensitive adhesive layer 5 . Wherein, the reflective layer 4 is a white composite layer, and the composite layer is made of polyurethane, polyester resin and acrylate.

[0029] The other side of the colored layer 3 is provided with a protective layer 2 . Wherein, the protective layer 2 is a capsule polyurethane layer. The other side of the protective layer 2 is provided with a temporary protective film 1 . The release paper 6 is provided with an air guide picture shape. its air guide picture The depth of the case is 10 μm.

[0030] The preparation method of described cast-grade car film comprises the steps:

[0031] S1. Preparation of protective layer or reflective layer: dissolve aliphatic polyurethane, poly...

Embodiment 2

[0037] Example 2 Except that the mass ratio of aliphatic polyurethane and polyester resin in steps S1 and S2 is 5:60; the mass ratio of polyester resin, solvent, auxiliary agent and functional material in the protective layer is 35:45:3:3 ; The mass ratio of polyester resin, solvent, auxiliary agent and functional material in the reflective layer is 25:35:3:20; the mass ratio of polyester resin, solvent, auxiliary agent and functional material in the color layer is 35:35 : 3:10; the mass ratio of aliphatic polyurethane, acrylate, solvent, additives, and functional materials in the pressure-sensitive adhesive layer is 20:30:2; the forced drying temperature in step S1 is 25°C, steps S1 and S2 The medium heat curing temperature is except that 25 ℃, other conditions are with embodiment 1;

Embodiment 3

[0039] Except that the mass ratio of aliphatic polyurethane and polyester resin in steps S1 and S2 is 40:95; the mass ratio of polyester resin, solvent, auxiliary agent and functional material in the protective layer is 45:55:8:8; the reflective layer The mass ratio of polyester resin, solvent, auxiliary agent and functional material is 35: 45: 8: 30; the mass ratio of polyester resin, solvent, auxiliary agent and functional material in the color layer is 45: 45: 8: 20; the mass ratio of aliphatic polyurethane, acrylate, solvent, additives, and functional materials in the pressure-sensitive adhesive layer is 40:40:30; the forced drying temperature in step S1 is 160°C, and heat curing in step S1 or S2 Temperature is other with embodiment 1 except 80 ℃;

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com