Environment-friendly processing equipment for thermal insulation ceramic tiles

A technology for processing equipment and thermal insulation ceramics, used in stone processing equipment, stone processing tools, work accessories, etc., can solve the problems of dust collection operation, cutting skew, unable to guide the operation of tiles, etc., and achieve efficient cutting operation and efficient forward operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

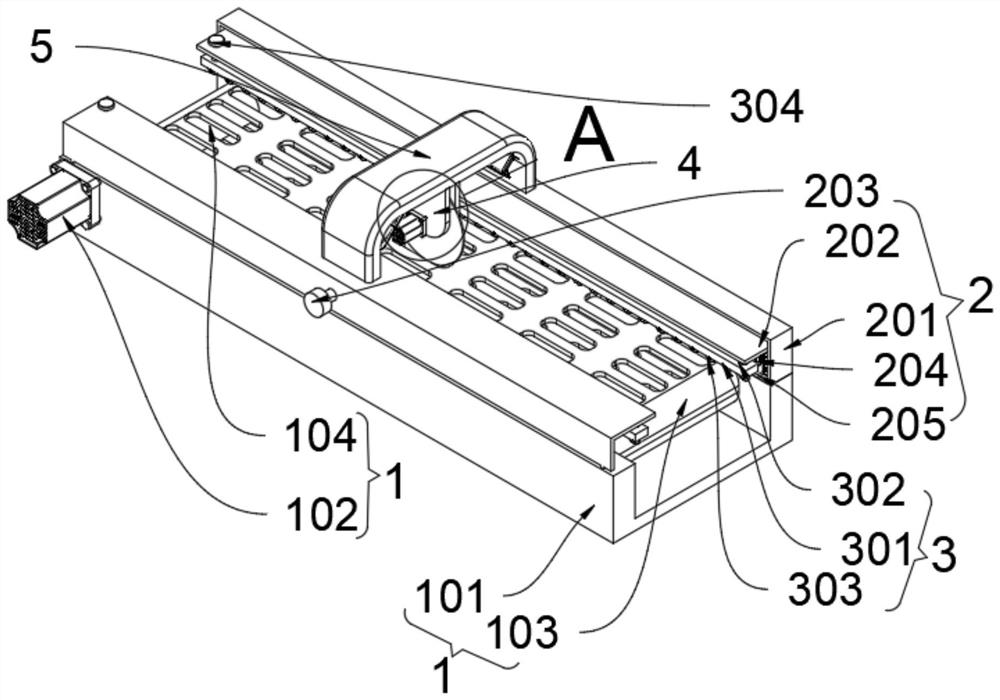

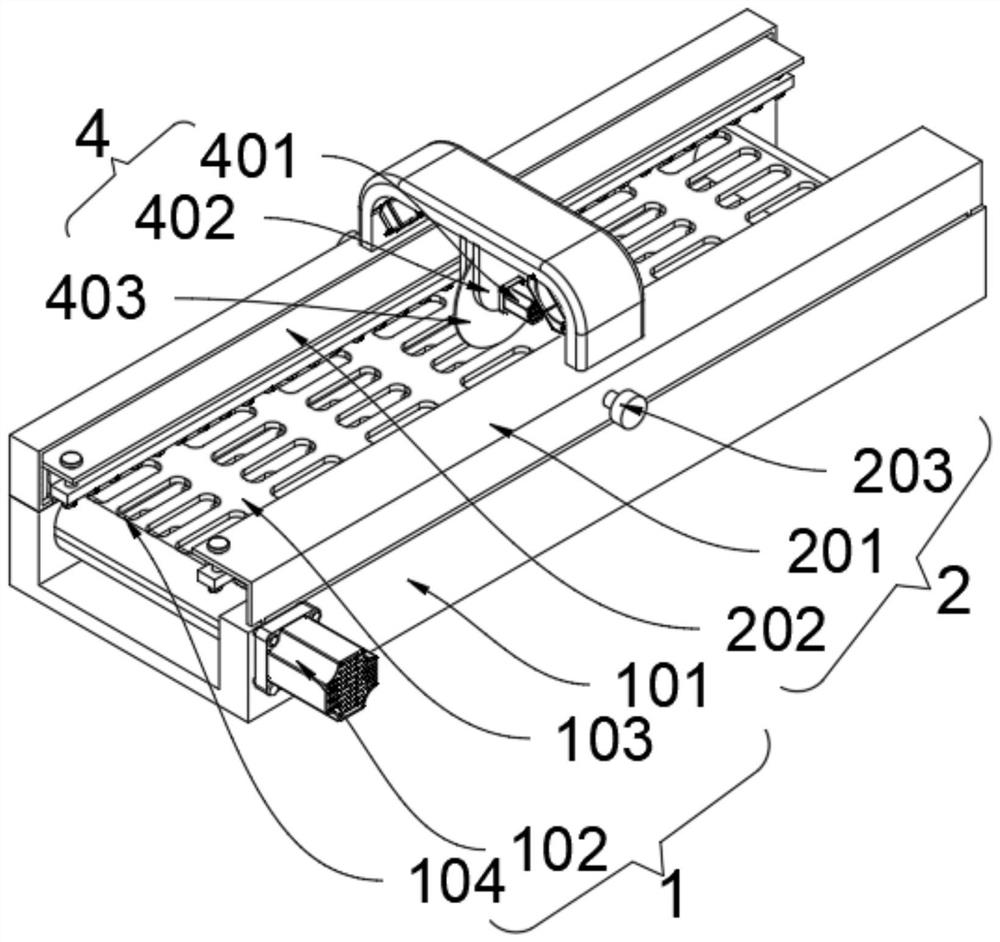

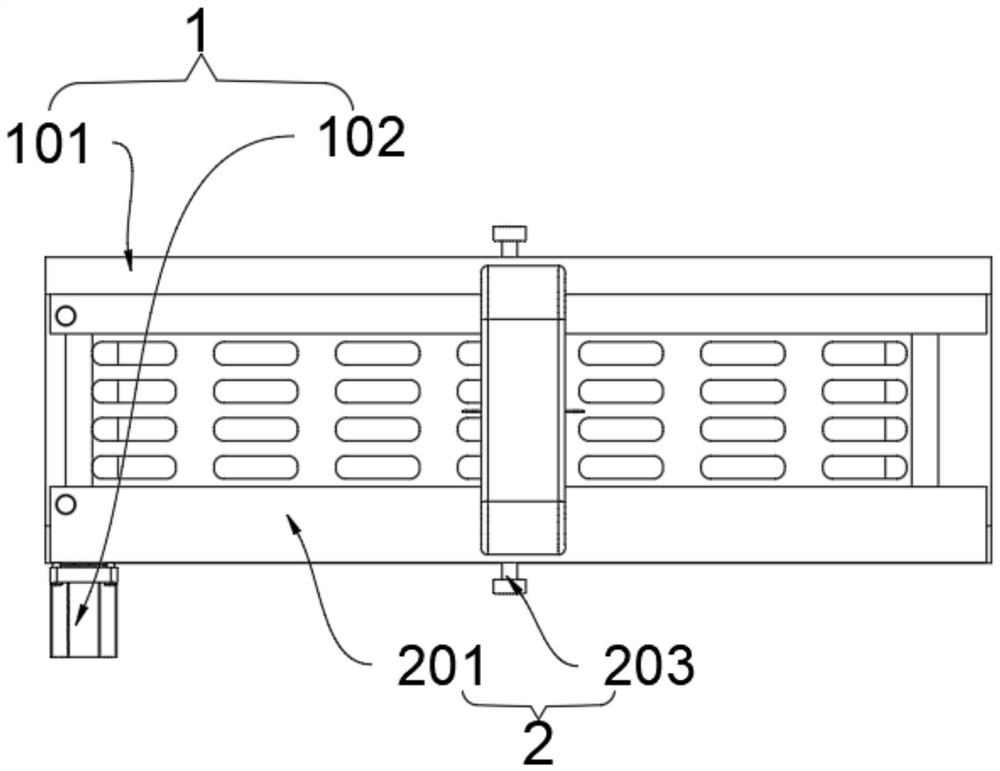

[0031] as attached figure 1 to attach Figure 8 Shown:

[0032] The invention provides an environmental protection processing equipment for thermal insulation ceramic tiles, including: a forward mechanism 2 and a dust removal mechanism 5, there are two forward mechanisms 2, and the two forward mechanisms 2 are respectively installed on the bearing mechanism The front and rear sides of the top of 1, and the guide mechanism 3 is installed on the inner side of the two forward mechanisms 2; There is a cutting mechanism 4; the dust removal mechanism 5 also includes a housing 503 and a dust-proof net 504. There are two housings 503 in total, and the two housings 503 are respectively sleeved on the outer positions of the two dust removal fans 502 to prevent dust. There are four nets 504 in total, and two dust-proof nets 504 form a group, and the two groups of dust-proof nets 504 are respectively installed on the upper and lower sides of the two housings 503 .

[0033]Wherein, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com