Environmentally friendly jelly glue and preparation method thereof

A jelly glue and environmental protection technology, applied in the field of environmental protection jelly glue and its preparation, can solve the problems of formaldehyde residue, glue opening, affecting the service life of products, etc., and achieve the effects of simple preparation method, stable heat resistance and excellent bonding performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

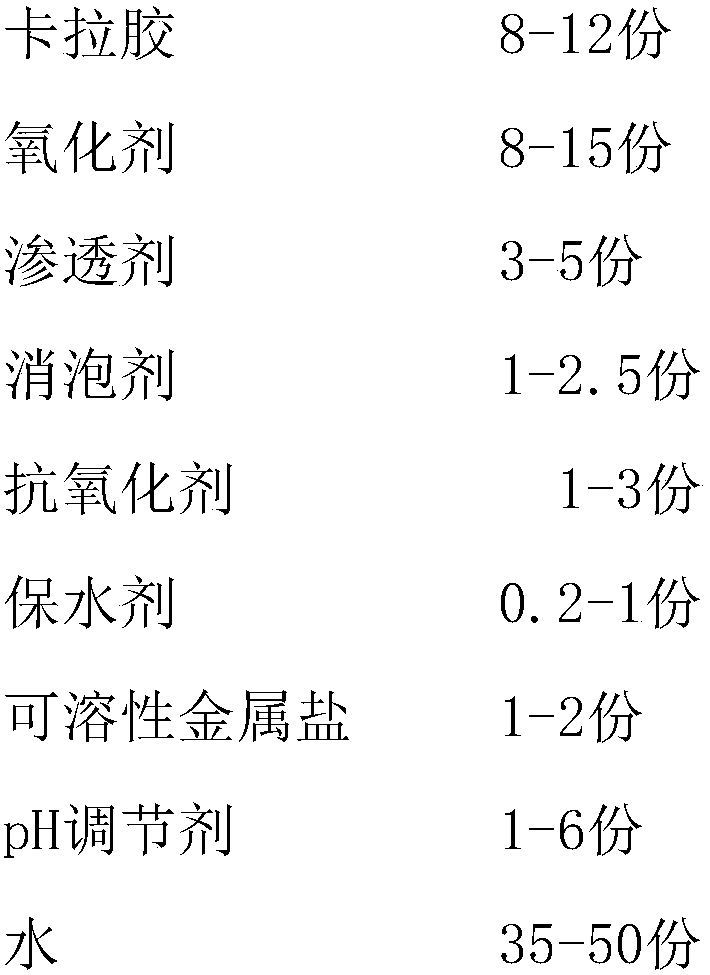

[0033] A kind of environment-friendly jelly glue, comprises the raw material of following weight portion:

[0034]

[0035] Wherein, carrageenan is the mixture that k-type carrageenan and I-type carrageenan form by weight ratio of 2:1;

[0036] The soluble metal salt is a mixture of potassium chloride and calcium chloride in a weight ratio of 1:2;

[0037] The water retaining agent is a mixture of starch graft copolymerized acrylamide and clay in a weight ratio of 2:1;

[0038] The clay is a mixture of bentonite and sericite powder in a weight ratio of 1:4;

[0039] The oxidizing agent is a mixed solution composed of 100g / L sodium hydroxide aqueous solution and 300g / L hydrogen peroxide aqueous solution in a volume ratio of 1:1.

[0040] The preparation method of above-mentioned environment-friendly jelly glue, comprises the following steps:

[0041] S1. Mix gelatin, konjac flour, carrageenan, water retaining agent and water according to the above parts by weight, raise the...

Embodiment 2

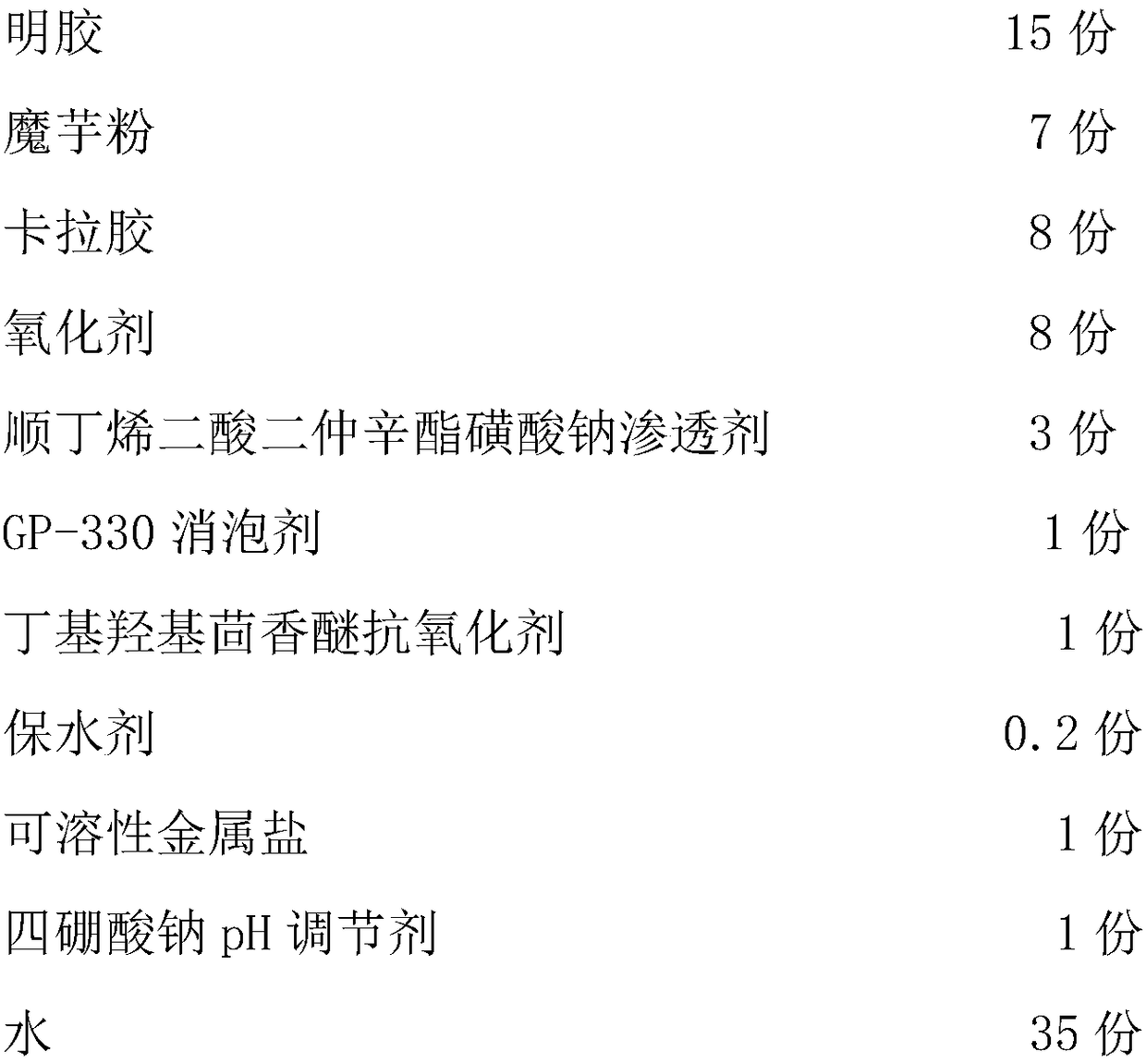

[0045] A kind of environment-friendly jelly glue, comprises the raw material of following weight portion:

[0046]

[0047] Wherein, carrageenan is a mixture of k-type carrageenan and I-type carrageenan in a weight ratio of 2.5:1;

[0048] The water retaining agent is a mixture of starch graft copolymerized acrylamide and clay in a weight ratio of 3:1;

[0049] The clay is a mixture of bentonite and sericite powder in a weight ratio of 1:5;

[0050] The soluble metal salt is a mixture of potassium chloride and calcium chloride in a weight ratio of 2:2;

[0051] The defoamer is a mixture of GP-330 defoamer and isooctyl alcohol defoamer in a weight ratio of 1:3;

[0052] The oxidizing agent is a mixed solution composed of 100g / L sodium hydroxide aqueous solution and 300g / L hydrogen peroxide aqueous solution in a volume ratio of 1:1.

[0053] The preparation method of above-mentioned environment-friendly jelly glue, comprises the following steps:

[0054] S1. Mix gelatin, ...

Embodiment 3

[0058] A kind of environment-friendly jelly glue, comprises the raw material of following weight portion:

[0059]

[0060]

[0061] Wherein, carrageenan is a mixture of k-type carrageenan and I-type carrageenan in a weight ratio of 3:1;

[0062] The water retaining agent is a mixture of starch graft copolymerized acrylamide and clay in a weight ratio of 4:1;

[0063] The clay is a mixture of bentonite and sericite powder in a weight ratio of 1:6;

[0064] The soluble metal salt is a mixture of potassium chloride and calcium chloride in a weight ratio of 3:2;

[0065] The oxidizing agent is a mixed solution composed of 100g / L sodium hydroxide aqueous solution and 300g / L hydrogen peroxide aqueous solution in a volume ratio of 1:1.

[0066] The preparation method of above-mentioned environment-friendly jelly glue, comprises the following steps:

[0067] S1. Mix gelatin, konjac flour, carrageenan, water retaining agent and water according to the above parts by weight, ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com