Perspective film

A technology of see-through film and transparent film, applied in the field of see-through film, which can solve the problems of slow punching speed, polluted screen, easy accumulation of dust and other problems of inkjet film, so as to meet the effect of light transmission and see-through, improve production efficiency, and avoid noise pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

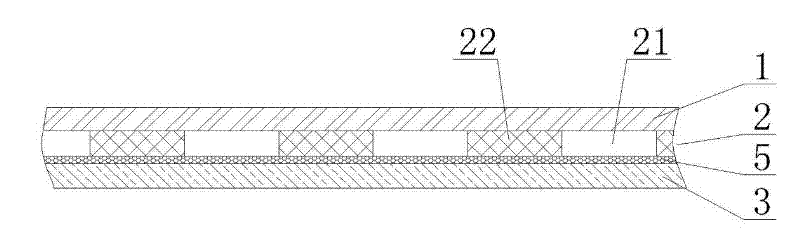

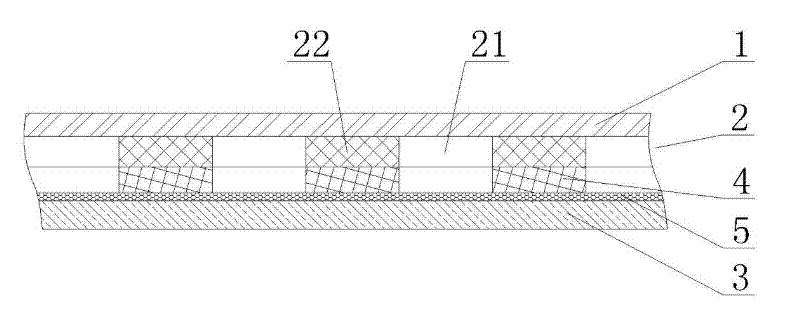

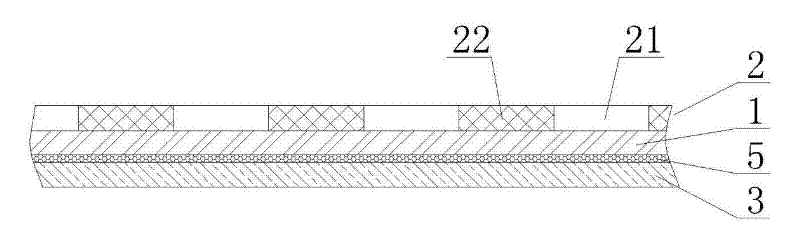

[0029] Such as Figure 1-Figure 11As shown, the see-through film of the present invention includes a transparent film 1 and a backing paper 3, and a color-developing printing layer 2 is printed on the transparent film 1, and the color-developing printing layer 2 is composed of color-developing printing bodies 22 and Light-transmitting area 21 is formed, and the picture sprayed on the surface of transparent film 1 can be displayed clearly through this color-developing printing layer 2; When the picture is displayed clearly, it can meet the light transmission and perspective effect. Since the transparent film 1 at the light transmission area 21 is also sprayed with the color of the picture, the picture sprayed on the front is clearer than the traditional one-way perspective sticker. Many, at the same time, so that people can also see the content of the sprayed picture from the reverse side of transparent plates such as glass and car windows. Moreover, in order to make the struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com