Prevulcanized annular crown of extra-large tire and its preparation method and application

A pre-vulcanization, tire crown technology, applied in the direction of tire tread/tread pattern, application, tire parts, etc., to avoid poor heat dissipation, avoid adverse effects, and improve heat dissipation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

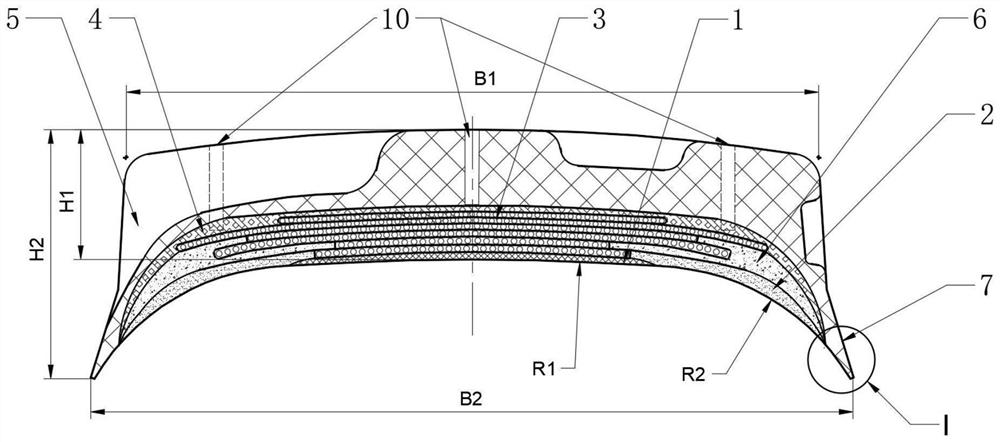

[0070] This embodiment is a pre-vulcanized annular crown of 59 / 80R63 extra-jumbo tire, which is characterized in that the middle section inside the section of the annular crown is a multi-section arc, and the inner side of the shoulder extension at both ends is an arc tangent to the middle section.

[0071] 1. After the tire is used, its size and structure are quite different from the new tire. Therefore, before retreading the tire, it is necessary to inspect the main body size and crown structure size of the corresponding new tire, and then determine the structural dimensions of the pre-vulcanized annular crown.

[0072] The new tire parameters are as follows:

[0073] The tire section width is 1490mm; the outer diameter is 4025mm; the driving surface width is 1300mm; the driving surface arc radius is 3900mm; the pattern depth is 88mm.

[0074] The basic size of the annular crown is the same as that of a new tire, and the other main characteristic dimensions of the annular cr...

Embodiment 2

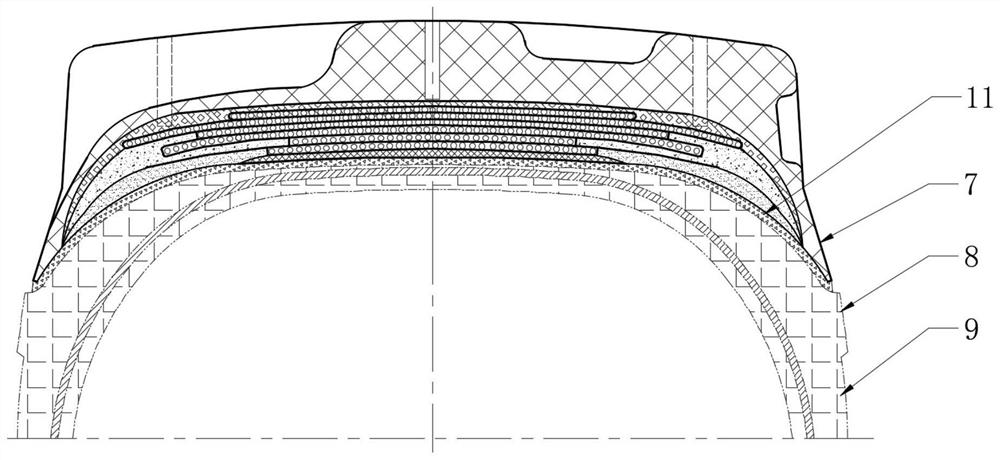

[0087] This embodiment is a pre-vulcanized annular crown of 59 / 80R63 extra-jumbo tire, which is characterized in that the middle section inside the section of the annular crown section is a multi-section arc, and the inner side of the shoulder extension at both ends is a tangential arc transition with the middle section. straight line.

[0088] The same parts of the new tire parameters and the main characteristic dimensions of the annular crown are referred to in Example 1. The difference is that the inner side of the tire shoulder extension 7 is a straight line tangent to the arc, and the angle between the straight line and the center line of the section is 35°. °, the radius of the transition arc between the straight line and the inner surface of the crown is 100mm.

[0089] According to the above size data, a pre-vulcanized annular tire crown for extra-large tires is realized as follows:

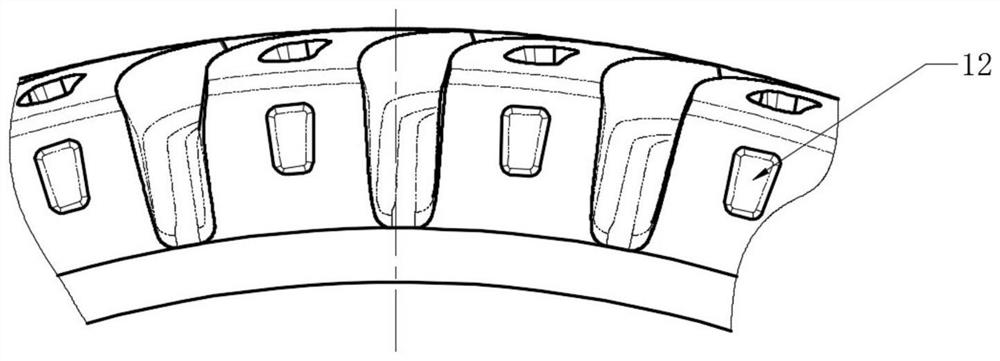

[0090] like Image 6 As shown, the pre-vulcanized annular rubber crown includes the...

Embodiment 3

[0096] The difference between this embodiment and Embodiment 1 is that blind holes 10 for installing sensors are distributed on the surface of the tread rubber, and the bottom ends of the blind holes 10 are located between the base rubber and the belt layer.

[0097] The tread adds a preset blind hole for sensor installation. When it is necessary to install a tread sensor to monitor the use of extra-large retreaded tires, it can be installed directly without drilling holes on the tread surface, which can improve the position accuracy of the later sensor installation. and work efficiency. The blind hole of the tread corresponds to the raised cylindrical structure on the vulcanization mold. The cylindrical structure is in the pattern block during vulcanization, which increases the heat transfer point inside the tread compound and can improve the heat in the tread during vulcanization. The distribution state is beneficial to the vulcanization uniformity of the pattern block rubbe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com